Horizontal engine

An engine, horizontal technology, applied in the direction of engine components, machines/engines, engine cooling, etc., can solve the problems of high heat load, inability to cool the heat of the heat sink, slow speed increase, etc. Efficiency, the effect of improving the air passage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

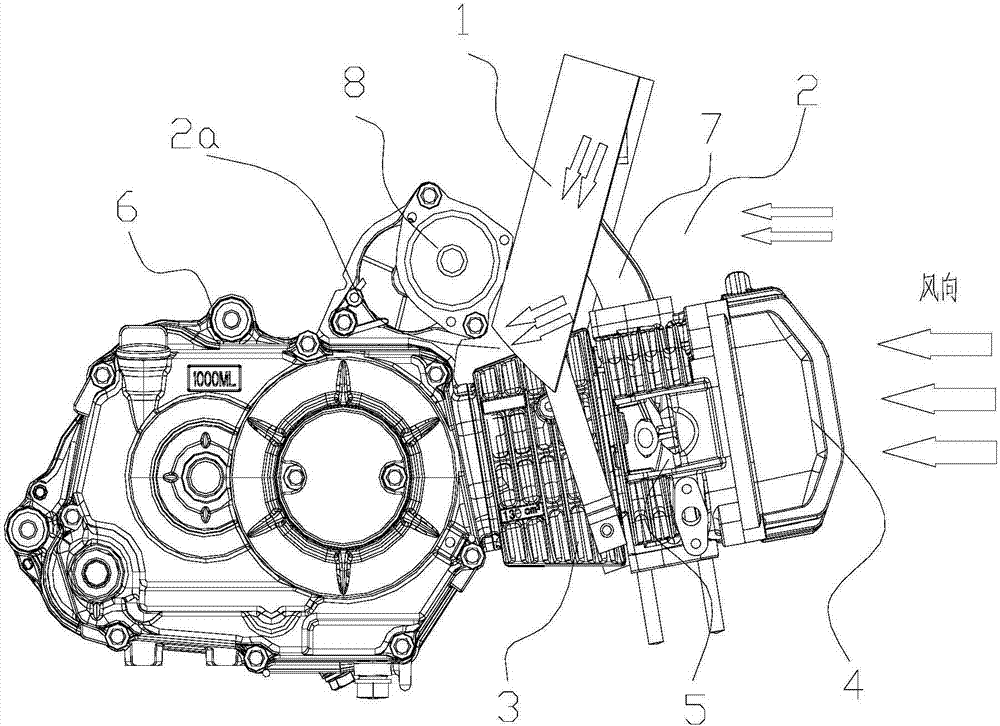

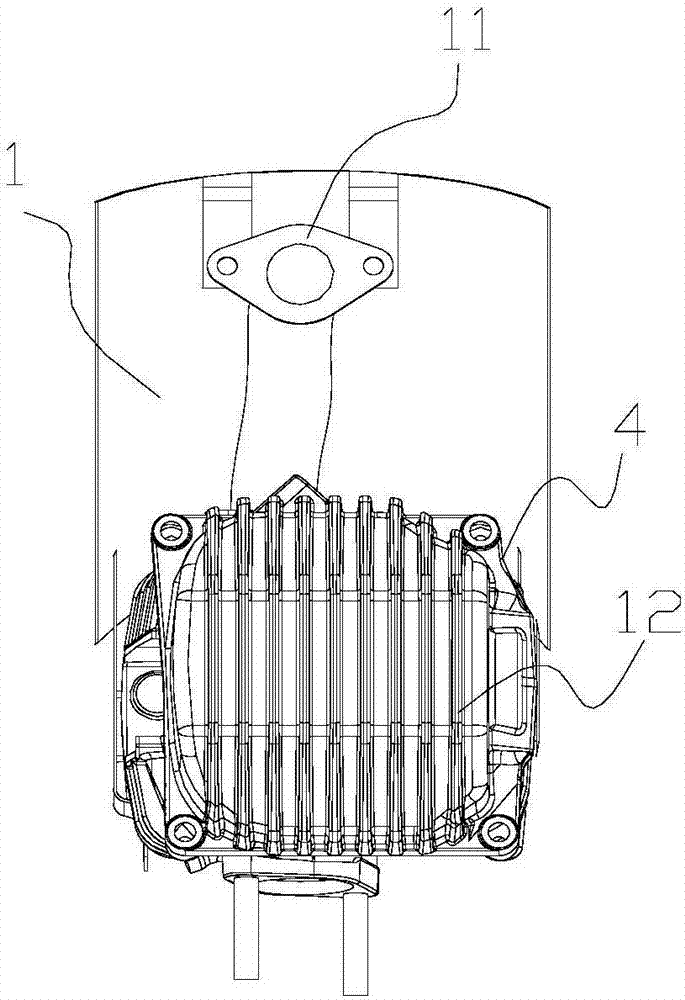

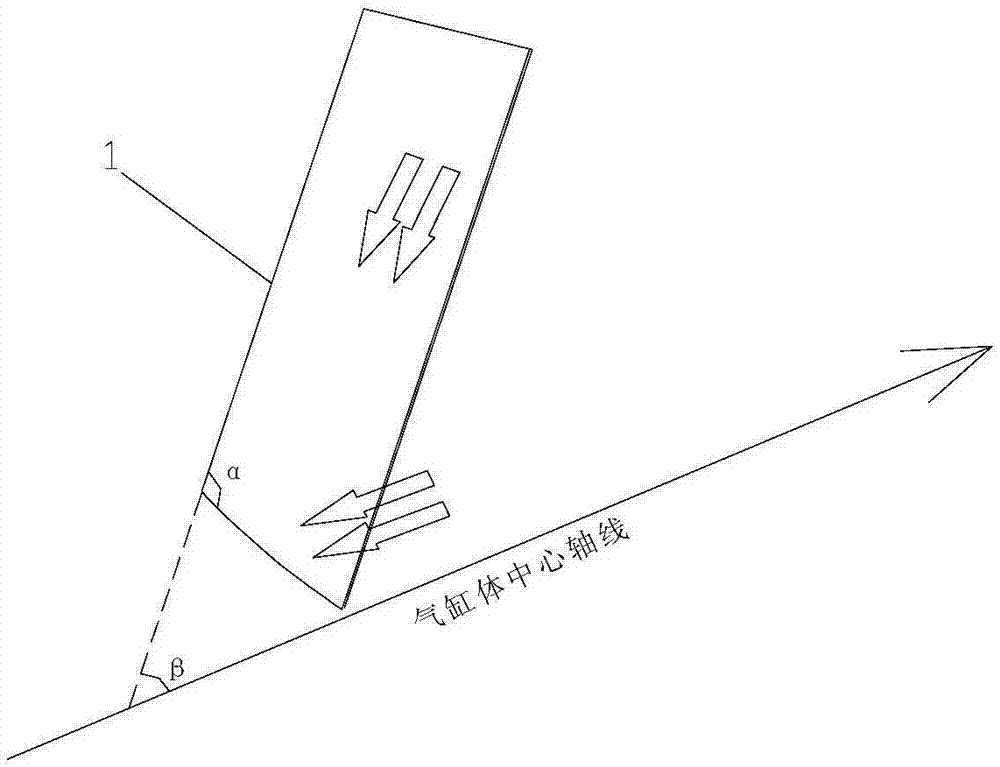

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 right view of the image 3 It is a schematic diagram of the angle of inclination of the wind gathering plate and the lower end surface of the wind gathering plate in the present invention, Figure 4 It is a structural schematic diagram of the connection assembly in the present invention. As shown in the figure, the horizontal engine in this embodiment; A wedge-shaped space 2 with a large front and a small rear is formed between the wind collecting plate 1 and the horizontal engine; the wedge-shaped space 2 is used as an air guide for cooling the horizontal engine; the wind collecting plate is fixed by casting, welding or detachable Fixed on the horizontal engine; the wind accumulating plate can be located above the cylinder block of the horizontal engine. The components with the largest heat generation of the horizontal engine are the cylinder block and the cylinder head. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com