Device for measuring air intake flow of engine

A technology of air intake flow and measurement devices, which is applied in the direction of measurement devices, engine testing, machine/structural component testing, etc., can solve problems such as large errors, high costs, and restrictions on pipeline layout, and achieve small impact and fast response Fast, small pressure loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

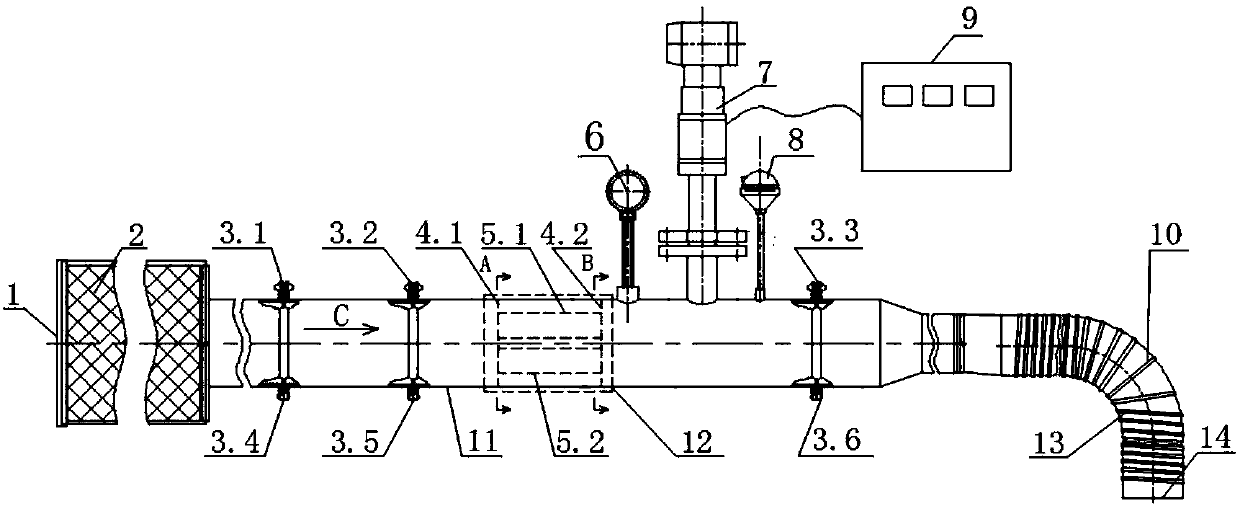

[0015] Below in conjunction with accompanying drawing, the utility model is further described:

[0016] Such as figure 1 As shown, an engine air intake flow measurement device includes an air inlet 1, a pressure transmitter 6, an air flow meter 7, a temperature sensor 8, an air pipeline 11, and an air connection port 14, which is characterized in that the air pipeline Air filter 2 is housed at the air inlet 1 place of 11 one ends, is used for preventing intake air duct 11 from being polluted.

[0017] The air connection port 14 of the other end of the air pipeline 11 is equipped with a steel wire hose 10 that is convenient to be connected with the engine air inlet. The steel wire hose 10 is embedded with a steel wire 13, which can prevent the unstable air pressure in the pipe from deforming the hose.

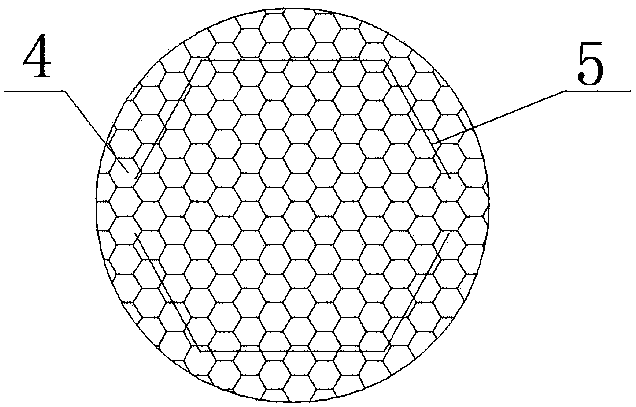

[0018] The air pipeline 11 is also equipped with a honeycomb rectifier 12, which can balance the internal pressure, reduce errors, and reduce the length of straight pipe sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com