A fluidized bed slag cooling system and method with biomass gasification and co-combustion function

A fluidized bed and biomass technology, applied in the energy field, can solve the problems of large heat loss in slag discharge and lack of matching high-efficiency slag cooling methods, etc., to achieve the effects of ensuring slag discharge, prolonging the gas-solid contact time, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

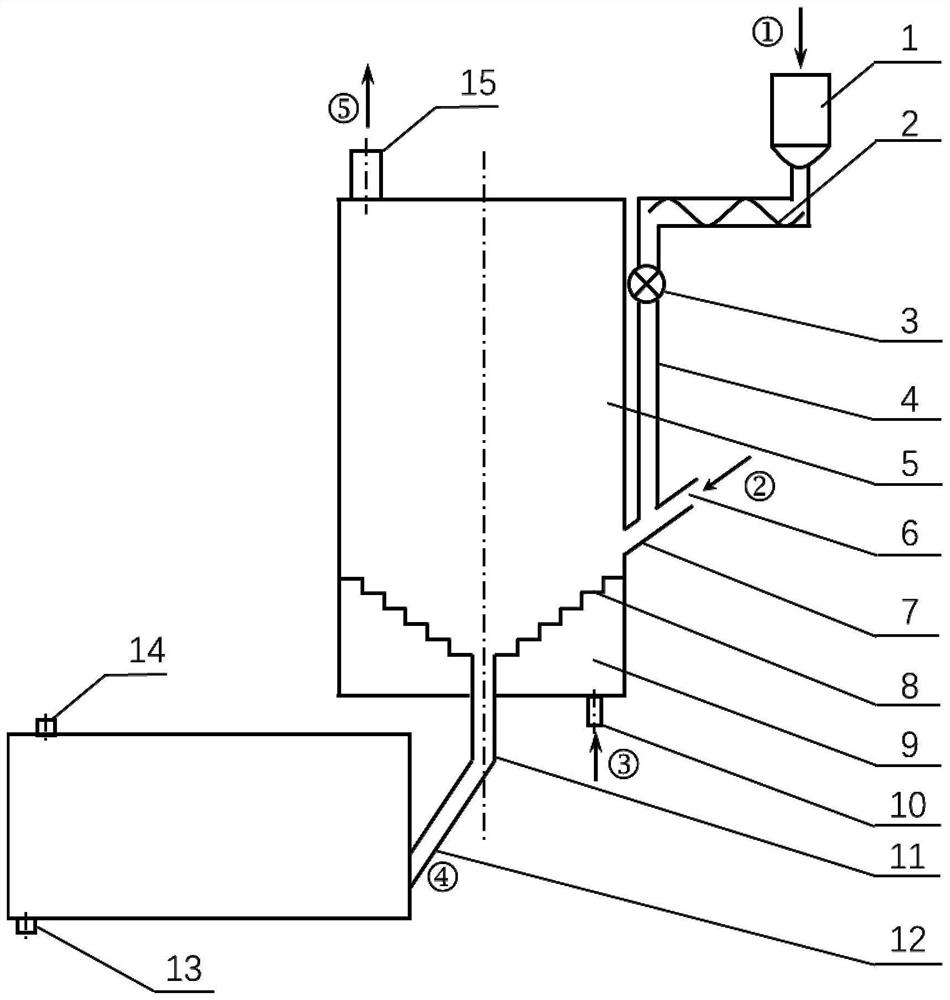

[0050] The structural representation of specific embodiment one and figure 1 Consistent, the operation mode of the fluidized bed cooling slag system with biomass gasification co-combustion function is the same as the above.

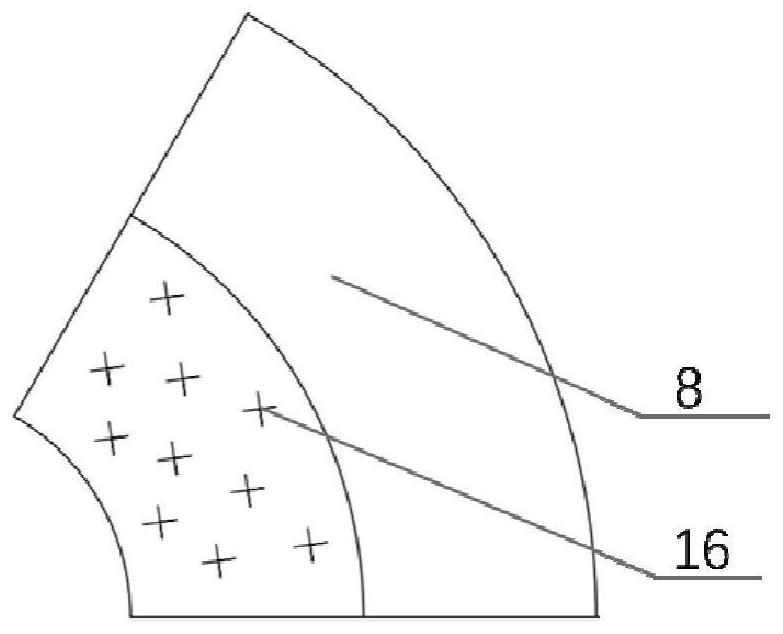

[0051] In particular, the structural parameters of the fluidized bed gasification unit are as follows: the height-to-diameter ratio of the gasification chamber is 12, the inverted conical air distribution plate 8 has a width-to-height ratio of 3, and the air distribution plate is annular and stepped, with 9 layers in total. Such as figure 2 As shown, the width of each air distribution plate is 60mm, and each layer of air distribution plate is provided with 4 rows of vertical air distribution holes 16, the diameter of the vertical air distribution holes is 4mm, and the air distribution holes are arranged in a staggered arrangement with an opening rate of 1.5%. Each layer of air distribution plate is provided with 2 rows of horizontal air distribution hol...

specific Embodiment 2

[0054] The structural representation of specific embodiment one and figure 1 Consistent, the operation mode of the fluidized bed cooling slag system with biomass gasification co-combustion function is the same as the above.

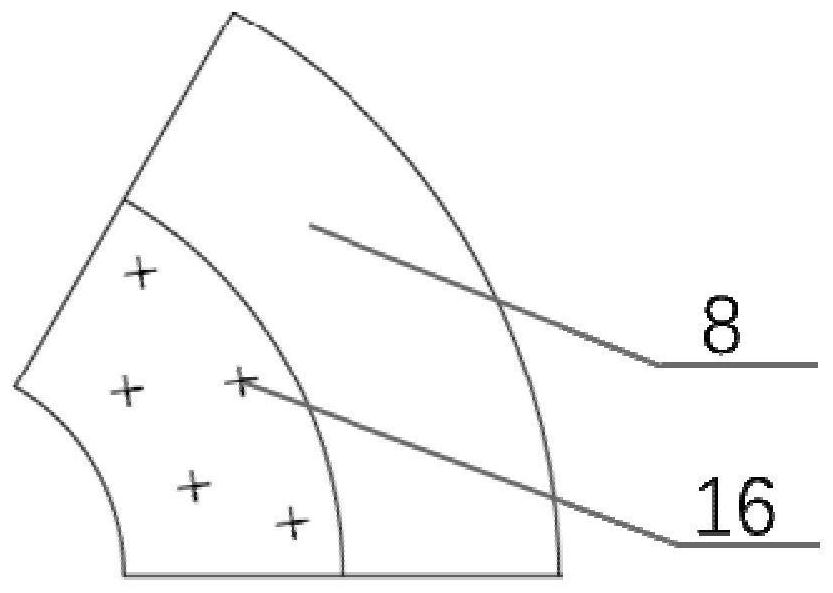

[0055] In particular, the structural parameters of the fluidized bed gasification unit are as follows: the height-to-diameter ratio of the gasification chamber is 9, the inverted conical air distribution plate 8 has a width-to-height ratio of 2, and the air distribution plate is annular and stepped, with 8 layers in total. Such as image 3 As shown, the width of each air distribution plate is 40mm, and each layer of air distribution plate is provided with 2 rows of vertical air distribution holes, the diameter of the vertical air distribution holes is 2mm, the air distribution holes are arranged in staggered arrangement, and the opening rate is 0.8%. Each layer of air distribution plate is provided with a row of horizontal air distribution holes, the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com