Combustion supporting, coal saving, modified additive

An additive and modification technology, which is applied in the field of coal-saving additives, can solve the problems of insufficient technology, difficulty in popularization, and large negative effects, so as to reduce the emission of smoke and harmful gases, reduce the heat loss of exhaust smoke, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

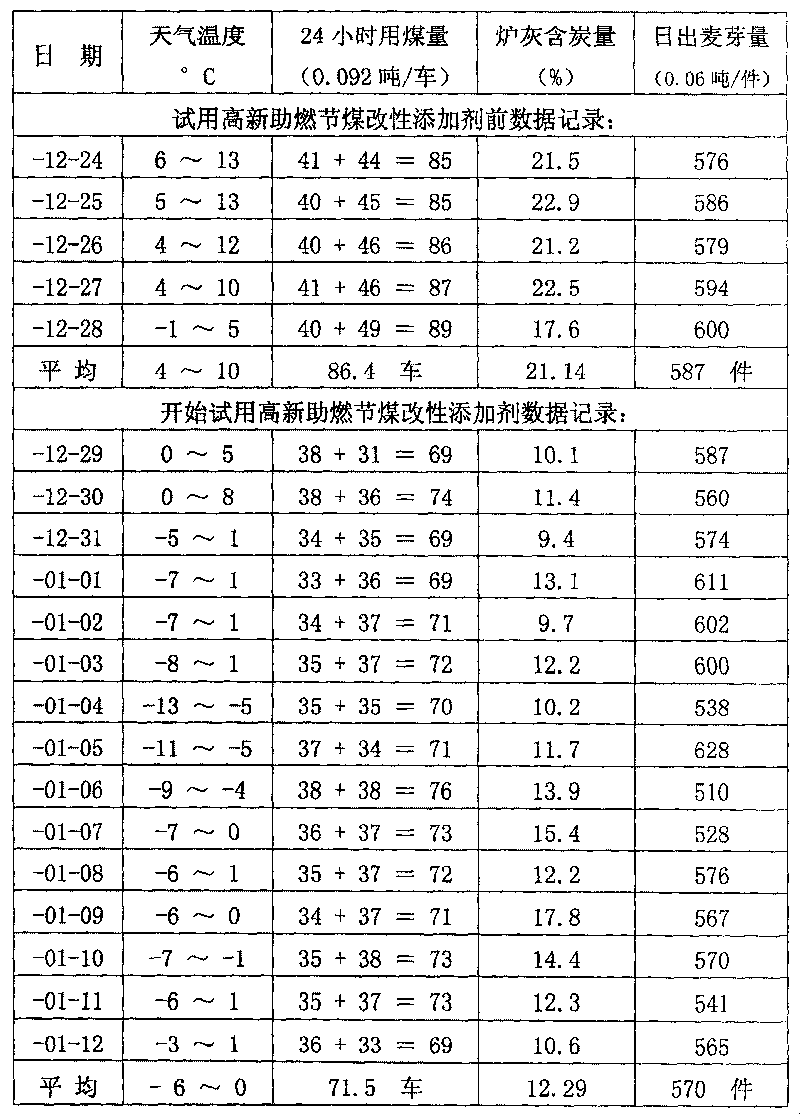

Examples

Embodiment 1-7

[0030] 1. Select the raw material slag and industrial waste slag that meet the content requirements respectively according to the proportion and technical requirements, and crush them to a fineness of 80 mesh to 300 mesh with a rubber iron mill, cool naturally, and set aside;

[0031] 2. According to the order of reducing agent→expansion agent→sulfur-fixing agent descaling→smoke cleaner→catalyst→oxidant, add them into the stirring tank in proportion, stir and homogenize for 1 minute, and the total amount of each batch should not exceed 1 ton;

[0032] 3. Put the evenly stirred material in a cool and dry place to passivate for 24 hours;

[0033] 4. After passing the inspection, the measured packaging is 25kg / bag, the outer layer is a polypropylene woven bag, and the inner layer is a plastic bag; storage is required to be stored in a dry and cool place, not exposed to the sun, rain, and not afraid of freezing. Example 1:

Embodiment 1

[0034] KClO 4 : 18 kg, NaNO 3 : 7 kg, MgO: 11 kg, Fe 2 o 3 : 6 kg, CaCO 3 : 15 kg, C 6 h 12 N 4 : 4 kg, Ba(NO 3 ) 2 : 13 kg, KCl: 12 kg, mAl 2 o 3 -nSiO 2 -xH 2 O: 4.3 kg, MgSiF 6 -6H 2 O: 9 kg. This optimized ratio scheme is suitable for cement calcining shaft kiln.

Embodiment 2

[0036] MnO 2 : 15kg, KNO 3 : 8.8 kg, K 2 CO 3 : 9 kg, SiO 2 -nH 2 O: 2 kg, Al 2 o 3 : 13 kg, MgCO 3 : 6 kg, NaOH: 5 kg, KClO 3 : 11 kg, CaO: 10.7 kg, NaCl: 20% kg. This optimal ratio scheme is suitable for circulating fluidized bed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com