Controller of acid seed reaction time for cotton seed delinting in acid solution

A technology of reaction time and cotton seed acid, applied in application, seed and rhizome treatment, agriculture, etc., can solve problems such as high residual acid, affecting germination rate, seed damage, etc., and achieve the effect of ensuring the quality of cashmere removal and saving sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] Specific implementation manners: the present invention is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

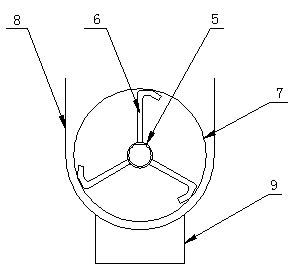

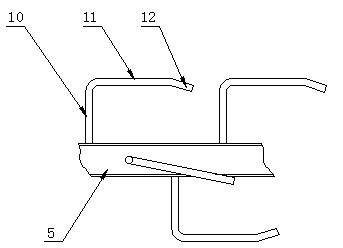

[0017] A cotton seed acid solution delinting acid seed reaction time controller, including a power drive device and a reaction propeller, the reaction propeller has a long open casing 8, the bottom surface of which is an arc concave surface, and the rotating shaft 5 is along the longitudinal direction of the casing 8 Erected on its two ends; the two ends of the rotating shaft 5 are respectively equipped with a feed auger blade 4 and a discharge auger blade 7, and the bottom of the casing 8 at the discharge auger blade 7 is provided with a discharge port 9, two auger blades Several gear rods 6 are evenly installed on the rotating shaft 5 between the blades; the reaction propeller is connected with the power driving device through the rota...

Embodiment

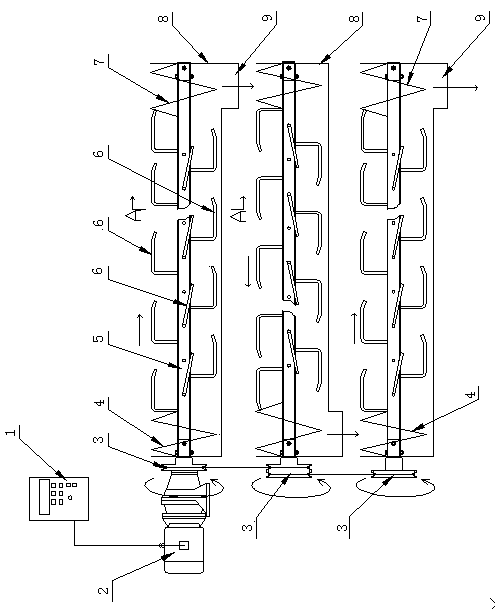

[0019] Example: such as Figure 1-3 As shown, a cotton seed acid solution delinting acid seed reaction time controller includes a frequency converter 1, a motor 2 and three sets of reaction propellers, the frequency converter 1 is connected to the motor 2, and the three groups of reaction propellers are arranged vertically to each other , the reaction propeller has an open casing 8 with an arc-shaped bottom surface, the rotating shafts 5 are mounted on both ends of the casing 8, the axis centerline coincides with the arc centerline of the bottom surface of the casing 8, and each rotating shaft 5 passes through the transmission outside the casing. The wheel 3 is connected with the motor 2, and the two ends of the rotating shaft 5 inside the casing 8 are respectively equipped with a feed auger blade 4 and a discharge auger blade 7, and an outlet is provided at the bottom of the casing 8 at the discharge auger blade 7. The opening position of the feed port 9 and the discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com