Uniform heating method for use in pipeline

A uniform heating and piping technology, applied in water heaters, heat storage heaters, fluid heaters, etc., can solve the problems of natural gas consumption, uneconomical, and not a long-term solution, and achieve safety management, environmental protection, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is illustrated by examples below, but the protection scope of the present invention is not limited thereto.

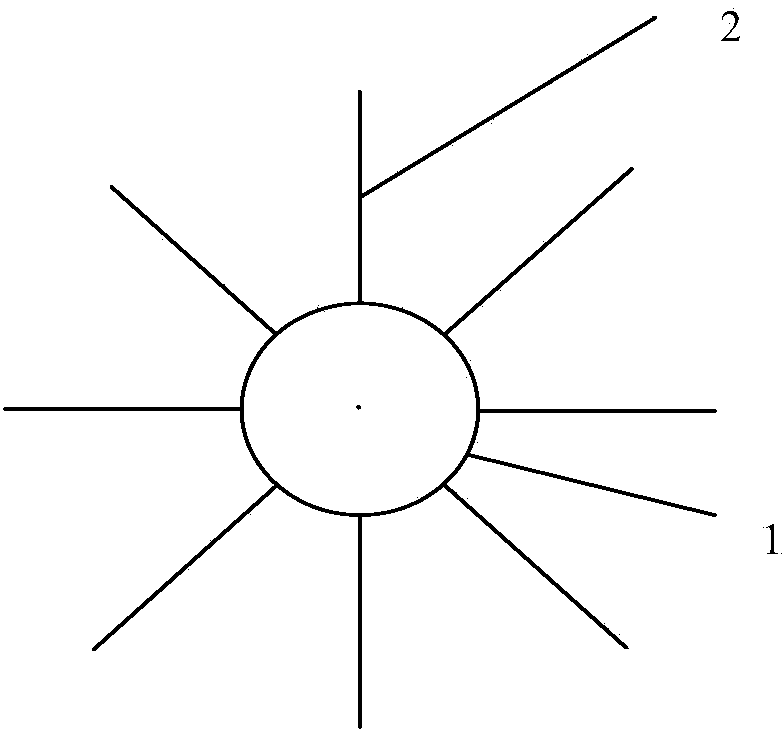

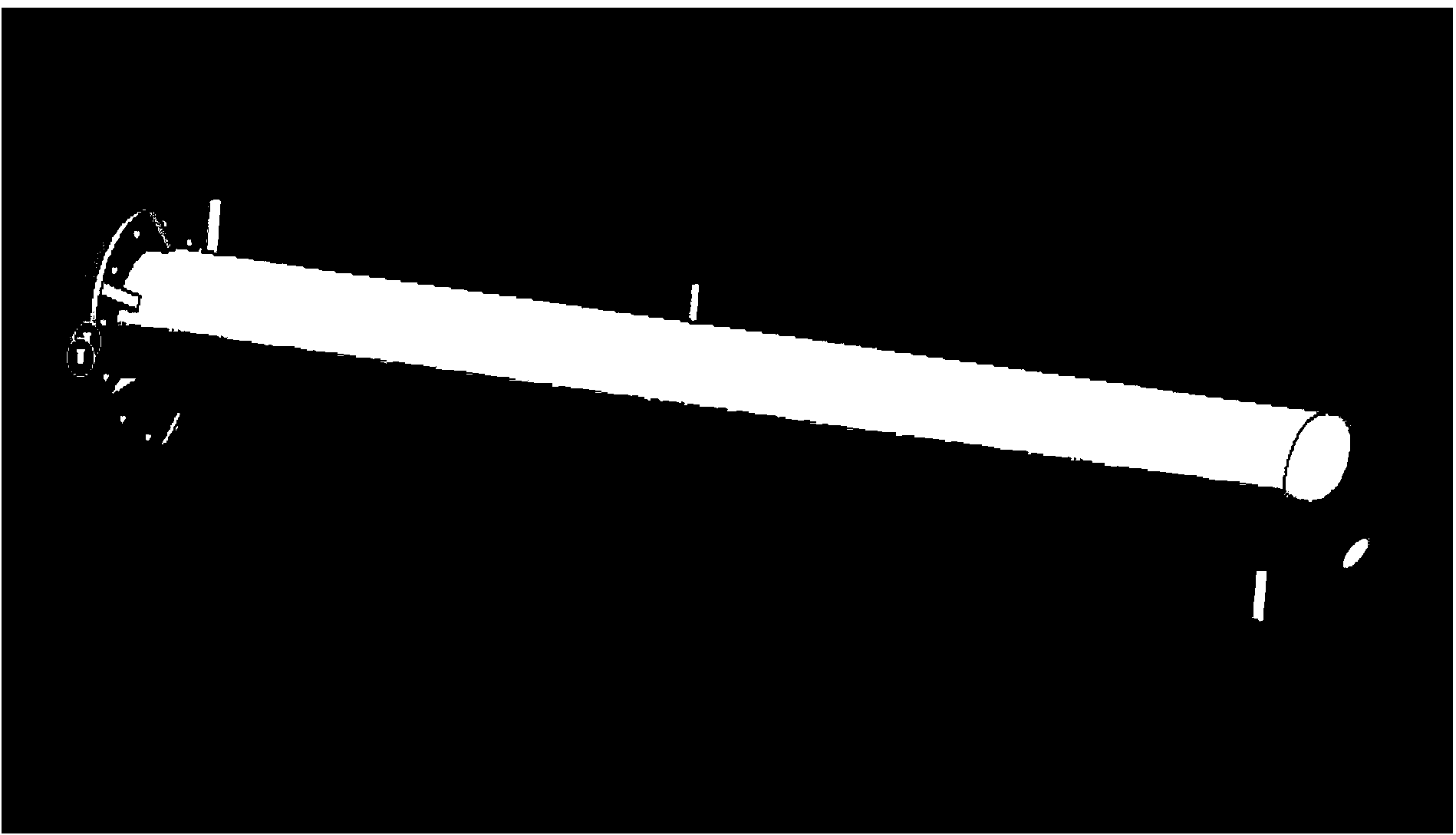

[0049] The invention provides a uniform heating method in a pipeline, which is characterized in that a fluid heat transfer device for heat transfer from the surface to the pipeline fluid is provided in the pipeline cavity; the fluid heat transfer device includes a tubular heat source supply part and a plate-shaped heat pipe, the The tubular heat source supply part is installed in the pipe along the axial direction of the pipe; the plate heat pipe connects with the outer wall of the tubular heat source supply part through its end along the heat conduction direction, and connects with the The plate-shaped heat pipe of the pipeline fluid heat transfer device transfers heat to the fluid in the pipeline.

[0050] In one embodiment of the method of the present invention, the pipeline includes a cavity (3), the cavity wall (4) of the pipeline is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com