Breeding method for special early season rice varieties for rice noodle processing

A technology for cultivar and early rice, applied in the field of rice breeding, can solve the problems of large measurement workload, high measurement cost, inability to separate offspring individual plants and lines to process rice vermicelli, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

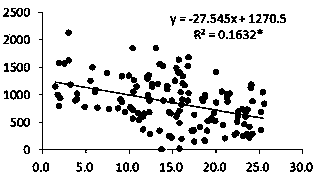

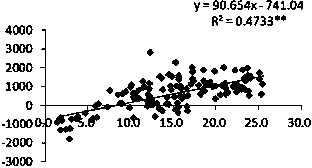

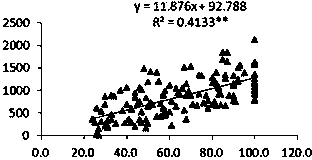

[0025] Four early rice varieties dedicated to rice flour and two common rice varieties were selected, and after roughening, fine grinding, and milling (the mill comes with a 80-mesh sieve), they were stored under the same conditions for later use. Adjust the weighing amount according to the moisture content to carry out the RVA spectrum determination, and the obtained spectrum is as follows Figure 5 Shown:

[0026] Compared with ordinary rice varieties, the early rice varieties for rice flour show that the viscosity drops more gently and the drop rate is smaller during the gelatinization and disintegration process, and the disintegration value is lower, while the viscosity rises larger during the cooling retrogradation process, and the retrogradation The value is higher, indicating that the disintegration value and retrogradation value can be used as indicators to measure the difference between early rice varieties dedicated to rice flour and ordinary rice varieties.

Embodiment 2

[0028] The RVA spectra of 10 early rice varieties (strains) dedicated to rice flour and 5 common rice varieties (strains) were measured, and the amylose content and gel consistency were measured at the same time. The results are shown in Table 1.

[0029] Table 1. Comparison of RVA spectrum characteristic values, amylose content and gel consistency of 10 early rice varieties (strains) dedicated to rice flour and common rice varieties

[0030]

[0031] The early rice varieties for rice noodles all show that the cold slurry viscosity is higher than the peak viscosity by more than 1000cP, that is, the retrogradation value is ≥1000cP, and the disintegration value is lower than 500cP. However, the disintegration value of ordinary rice varieties is mostly above 1000cP, while the retrogradation value is lower than 1000cP, and most of them are negative. Therefore, the amylose content of 25±1%, the retrogradation value ≥ 1000cP and the disintegration value ≤ 500cP are used as the pa...

Embodiment 3

[0033]1) Select rice varieties Zhongxuan 181 and Jiayu 253 with amylose content of 23.6% and 26.0% respectively, use a rapid viscometer to measure the peak viscosity of Zhongxuan 181 PKV=2195cP, cold pulp viscosity CPV=3714 cP, and disintegrate Value BDV=286cP, retrogradation value SBV=1519 cP; Jiayu 253 peak viscosity PKV=2450cP, cold slurry viscosity CPV=4423cP, disintegration value BDV=215cP, retrogradation value SBV=1973cP;

[0034] 2) Selected 181 as the female parent and Jiayu 253 as the male parent for hybridization;

[0035] 3) From F 2 At the beginning, select individual plants with excellent agronomic properties, harvest the seeds and perform RVA spectrum measurement after roughening, grinding, and milling, and keep the individual plants with SBV ≥ 1000cP and BDV ≤ 500cP, and plant the lines;

[0036] 4) F 3 Select excellent lines based on leaf shape, seed setting rate, resistance and yield, and select excellent individual plants from the excellent lines. Harvest t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com