Sterilizing tray utilizing ultraviolet lights

A technology of ultraviolet rays and disinfection boxes, applied in the field of sanitation and disinfection, can solve problems affecting reliability, accidents, equipment failures, etc., and achieve the effects of simplifying circuit wiring, simplifying equipment structure, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

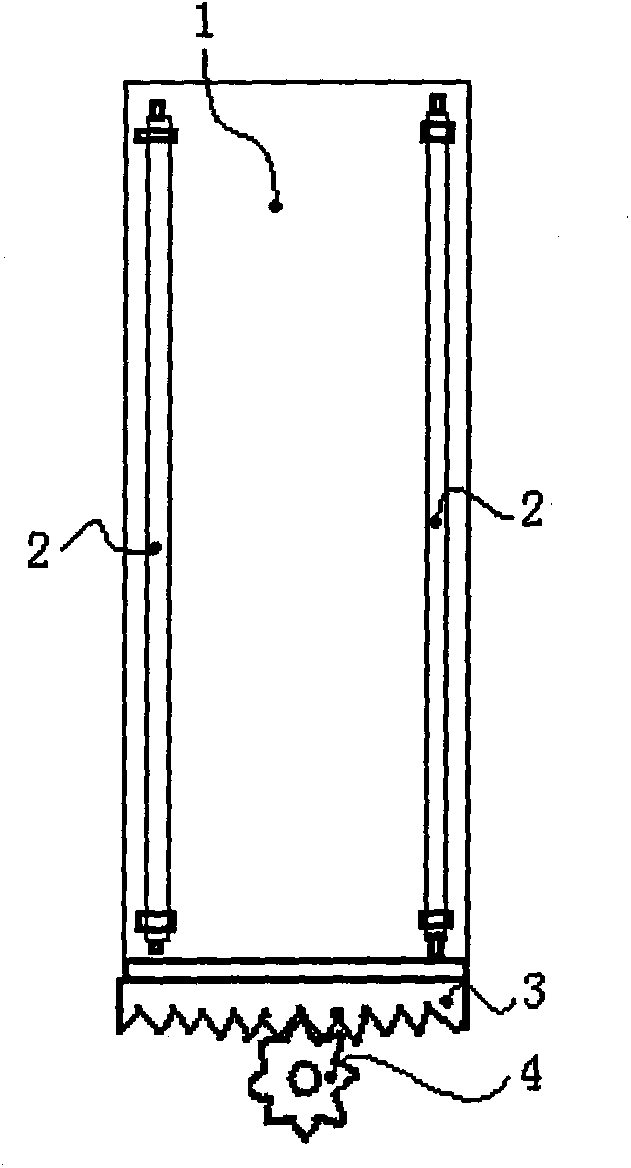

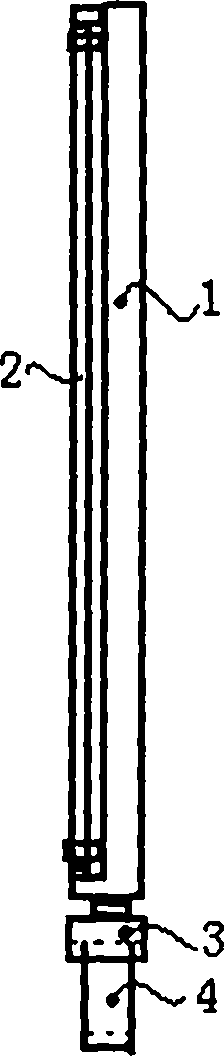

[0026] Figure 8 It is a schematic diagram of an ultraviolet disinfection box, which is composed of two protective frames 7 of ultraviolet lamps, ultraviolet lamps 2, a drive system, a timer, a power switch, and circuit components related to ultraviolet lamps. In the two protective frames, the ultraviolet lamps The pipe 2 is fixed on a plane plate surface 1, one side of the plane plate surface 1 is connected with the toothed slide bar 3 in the slideway 8 on the protective frame 7, and the toothed slide bar 3 is connected with the drive system. The 4 teeth of the output wheel are occluded and connected; when the disinfection operation is confirmed, first press the timer, when the two protective frames 7 of the ultraviolet disinfection box are closed, the power switch in the circuit is closed, the device is powered, and the ultraviolet lamp tube 2 lights up and emits ultraviolet rays that kill microorganisms such as bacteria and viruses, and the motor 6 (TY-50 synchronous motor)...

Embodiment 2

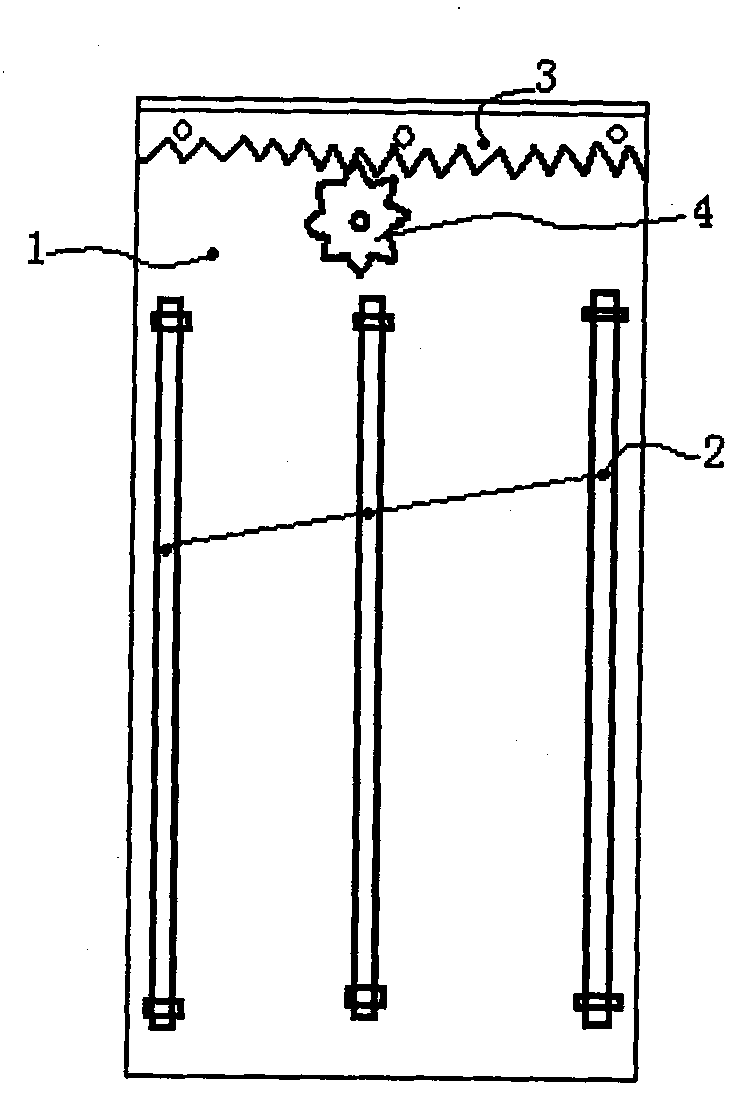

[0028] Figure 4It is a schematic diagram of another ultraviolet disinfection box, which is composed of protective frames 7 of two ultraviolet lamp tubes, ultraviolet lamp tube 2, drive system, timer and relevant circuit components of ultraviolet lamps. In the two protective frames, ultraviolet lamp tube 2 is Fixed on a plane deck 1, one side of the plane deck 1 is connected to the slide bar 31 in the slideway 8 on the protective frame 7, and the output wheel 4 of the motor 6 is connected to the slideway through the pull rope 5 The two ends of the slide bar (slide block) 31 in 8 are connected. When it is determined to carry out the disinfection operation, first press the timer, and when the two protective frames 7 of the ultraviolet disinfection box are closed, the power switch arranged on the protective frame 7 is closed, the device is powered, and the ultraviolet lamp 2 lights up and emits The ultraviolet rays that kill bacteria are emitted, and the motor 6 (TY-50 synchrono...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap