Novel dispenser with fluorescent powder thickness visual detection device

A visual inspection device and a technology for a glue dispenser, applied in the field of glue dispensers, can solve problems such as wasting productivity resources, and achieve the effect of improving automation procedures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings, but the embodiments of the present invention are not limited thereto.

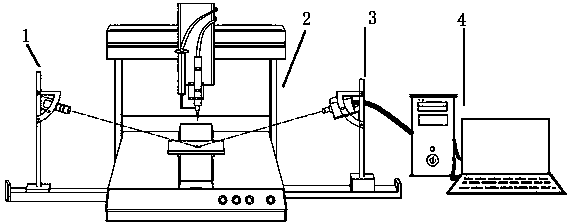

[0016] Such as figure 1 As shown, a new type of glue dispenser with a phosphor thickness visual inspection device includes the glue dispenser 2 and a visual inspection device arranged on the LED dispenser 2 for detecting the thickness of the phosphor.

[0017] Further, the visual inspection device includes a laser transmitter 1 arranged on a mechanical fixing device on one side of the dispenser 2 and a camera with image processing function arranged on a mechanical fixing device on the other side of the dispenser 2. 3. The camera is connected to the PC 4 in a circuit.

[0018] Further, the laser transmitter 1 and the camera 3 are fixed by a mechanical device, so that the emitted laser light hits the surface of the LED chip at a certain oblique and fixed angle, and the light reflected from the surface of the LED chip is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com