Demounting, mounting and maintenance tool for flotation machine

A technology of disassembly and maintenance, flotation machine, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reducing the operation rate, reducing the service life of the flotation machine, reducing the smoothness between components, etc., to prevent sudden changes. Rolling and falling, flexible and controllable adjustment methods, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

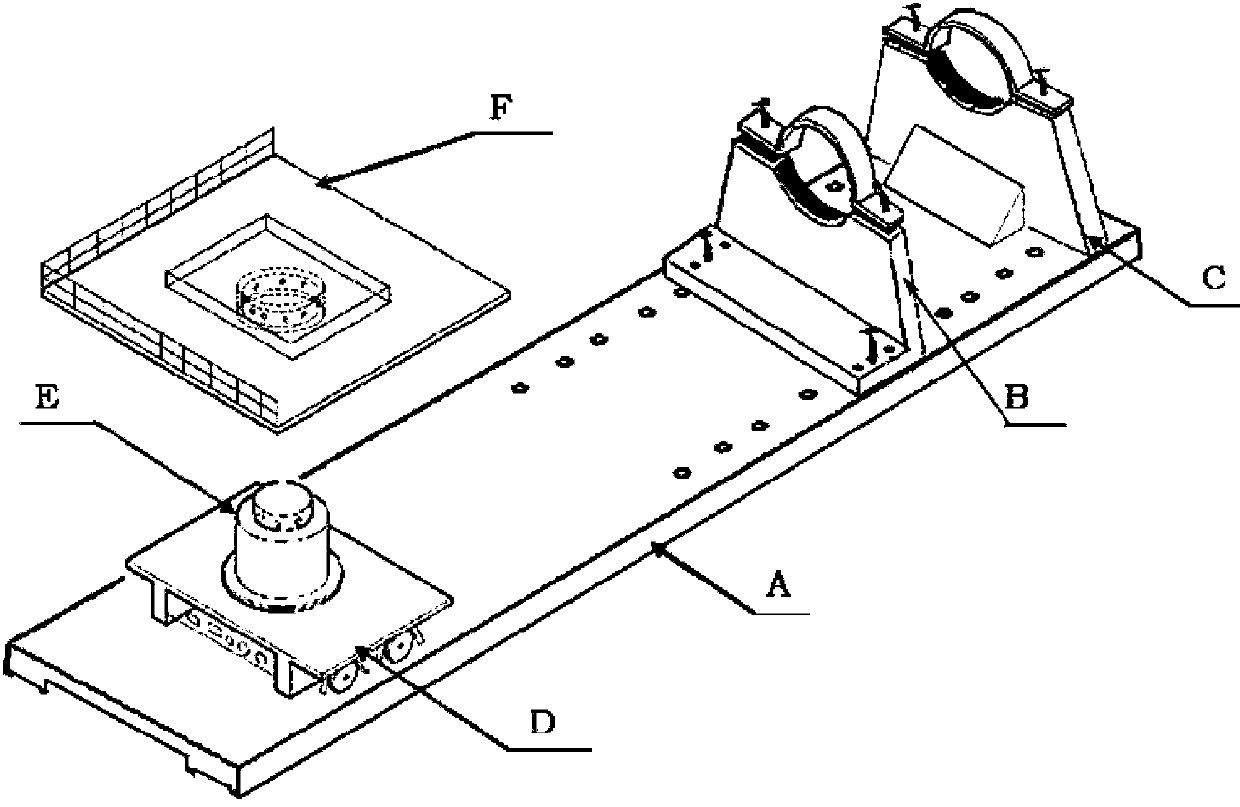

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

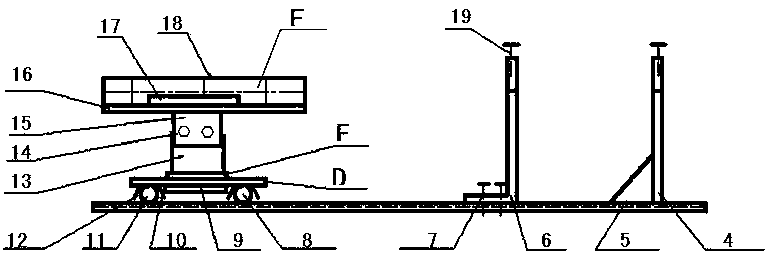

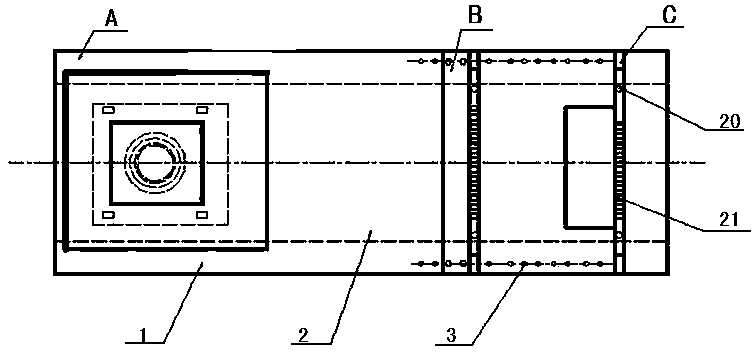

[0036] Such as Figure 1-3 As shown, the flotation machine disassembly and maintenance tools include base platform A, mobile support bracket B, fixed support bracket C, mobile rail car D, hydraulic lifting system E and maintenance pallet system F, the base platform A The right end is relatively installed with a mobile support bracket B and a fixed mobile support bracket C, and the left end of the base platform A is installed with a mobile rail car D, and a hydraulic lifting system E is installed on the mobile rail car D, and an inspection pallet system is installed above the hydraulic lifting system E F, as a whole constitutes a disassembly and maintenance tool for the flotation machine.

[0037] Wherein, the base platform A includes a channel steel track 1 and a steel plate 2, and the steel plate 2 is welded on the two channel steel trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com