Multi-shaft drilling-tapping machine tool

A machine tool and frame technology, applied in the field of multi-axis drilling and tapping machine tools, can solve the problems of high cost, high energy consumption, and high price of servo motors, and achieve the effect of cost reduction and energy saving of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

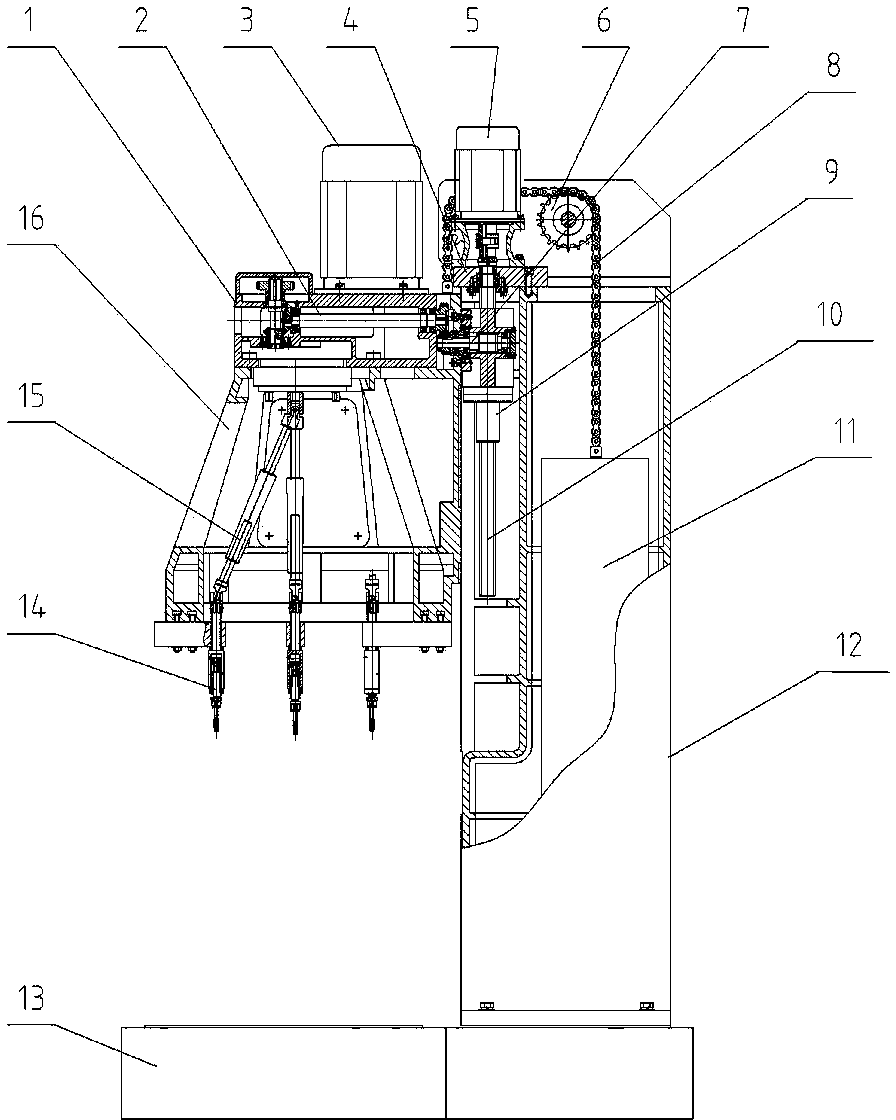

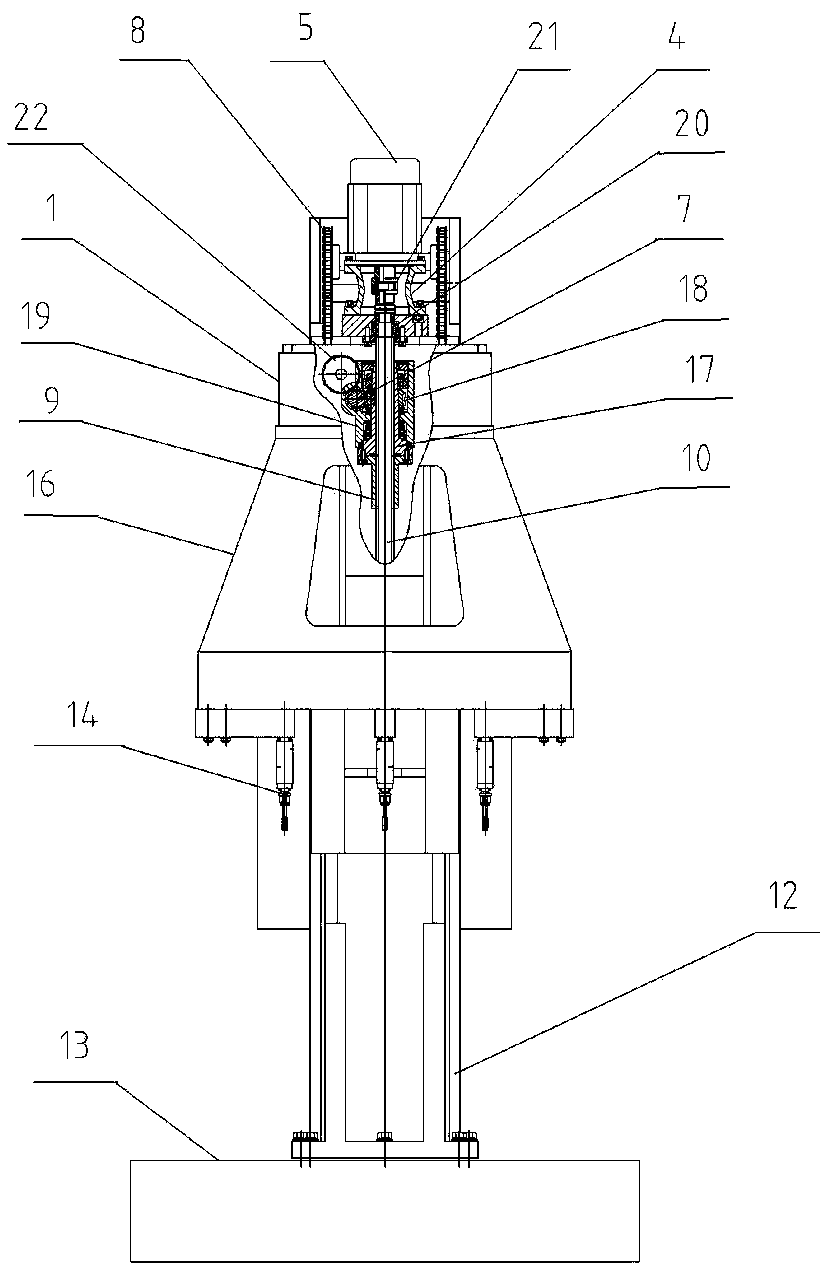

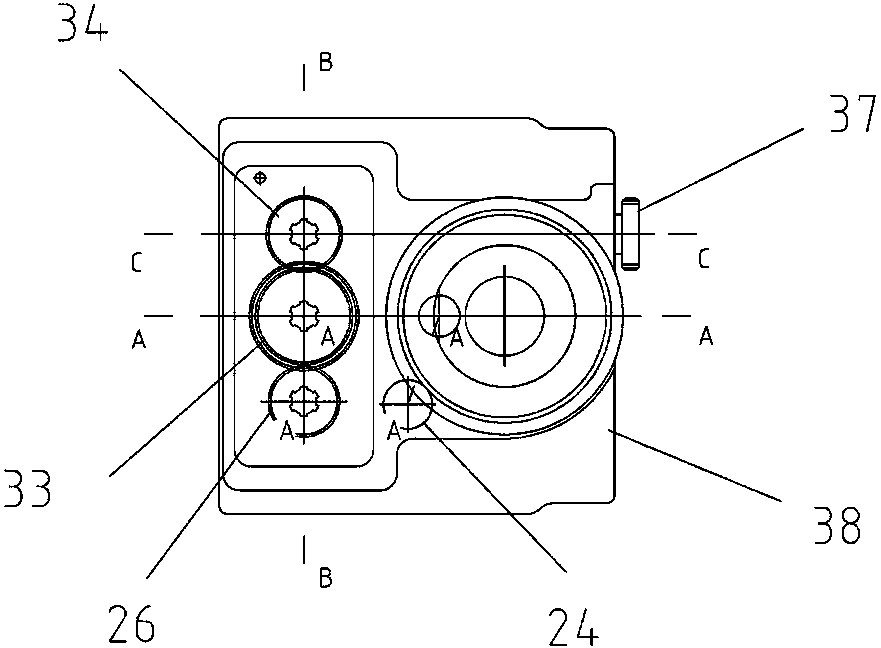

[0018] Description of drawings: gear box 1, power shaft 2, servo motor 3, motor bracket 4, drive motor 5, sprocket 6, worm 7, chain 8, screw nut 9, rotating screw 10, counterweight 11. Column frame 12, base 13, drill pipe assembly 14, universal joint assembly 15, power frame 16, worm gear shaft 17, worm gear 18, worm gear box 19, plane bearing 20, coupling 21, driving gear 22, the first One, the second duplex gear (23, 24,), the first driven gear 25, the replaceable transmission gear (26, 27), the second driven gear 28, the third and the fourth duplex gear (29, 30 ), transfer gear 31, second driven gear shaft 32, intermediate power gear 33, intermediate driven gear 34, intermediate driven gear shaft 35, bevel gear 36, working transmission gear 37, box body 38, rotating power Shaft 39, ball bearing 40, connecting screw 41.

[0019] Such as Figure 1 to Figure 8 As shown, a multi-axis drilling and tapping machine tool includes a column frame 12 installed on a base 13, and a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com