Automatic clamping mechanism of car acoustic component detecting tool

An acoustic component and automatic clamping technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of long detection time, low efficiency, unfavorable quality assurance detection products, etc., to achieve short operation time, high efficiency, cleverly structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

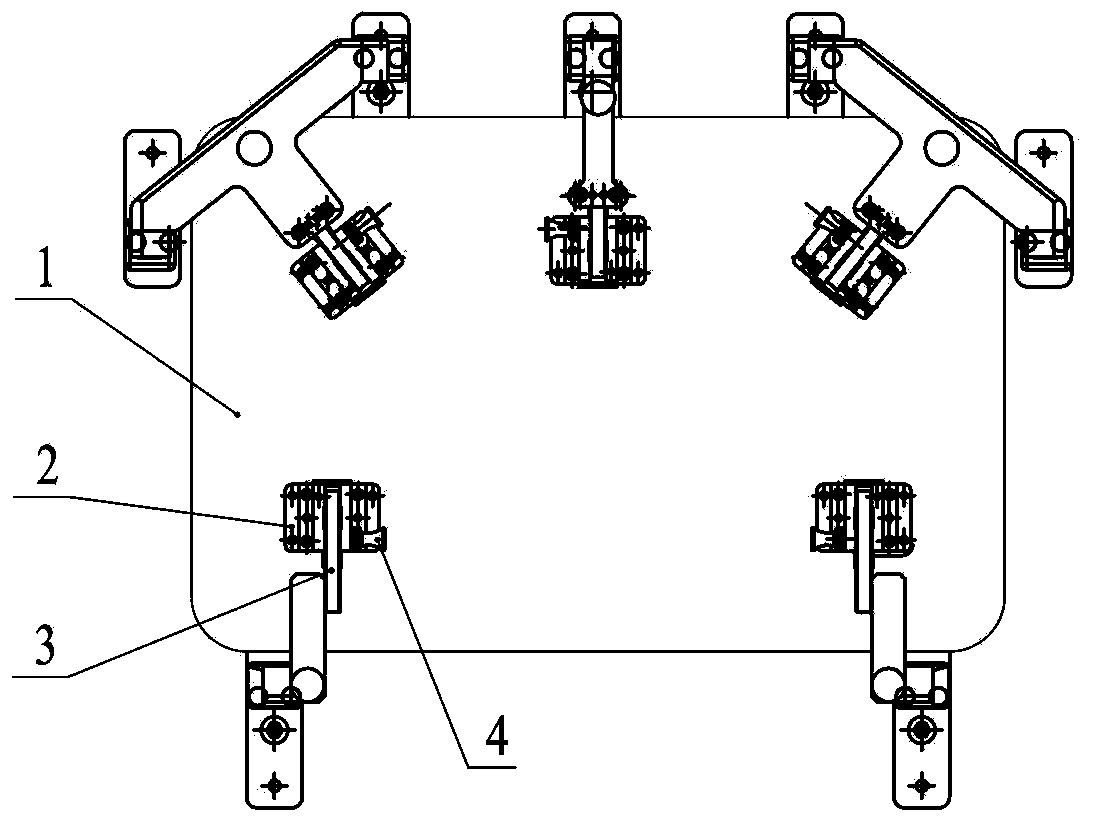

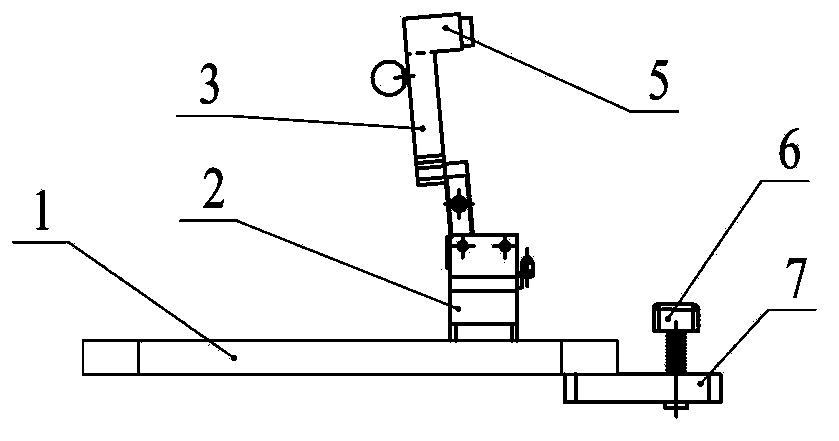

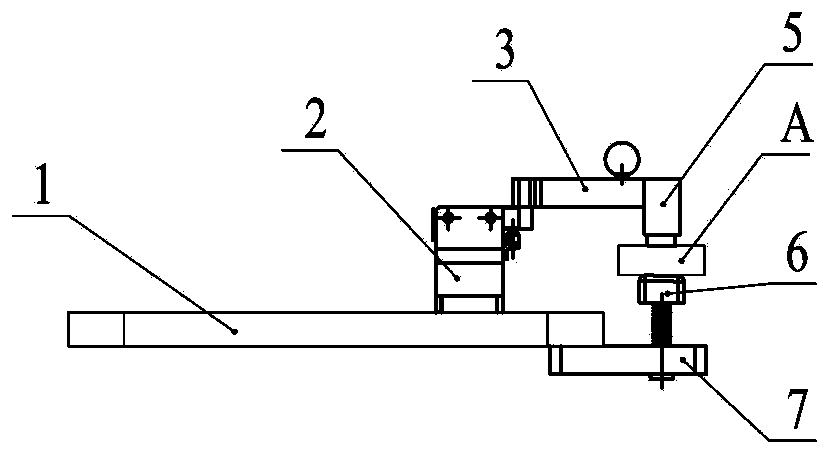

[0015] like Figure 4~Figure 6 As shown, the automatic clamping mechanism of the automobile acoustic component inspection tool in the embodiment is mainly composed of the inspection tool bottom plate 1, the fixing seat 2, the flip lever 3, the reference head 5, the lower buffer compactor 6, the connecting plate 7, and the cylinder connecting bracket 8 , overturn clamping drive cylinder 9, lower buffer clamping cylinder 10 and limit block 11 and other components.

[0016] like Figure 4~Figure 6 As shown, the fixed seat 2 is installed on the bottom plate 1 of the inspection tool, the connecting bracket 8 of the cylinder is fixed on the bottom of the bottom plate 1 of the inspection tool, and the cylinder end of the clamping drive cylinder 9 is hinged on the connecting bracket 8 of the cylinder when turned over and clamped. The piston rod end of the clamping dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com