Heavy-duty electric four-station wrist

A four-station, electric technology, applied in the direction of manipulators, metal processing, manufacturing tools, etc., can solve the problems of large moment of inertia, overrunning, and positioning discs that cannot be positioned accurately, and achieve the effect of improving versatility and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

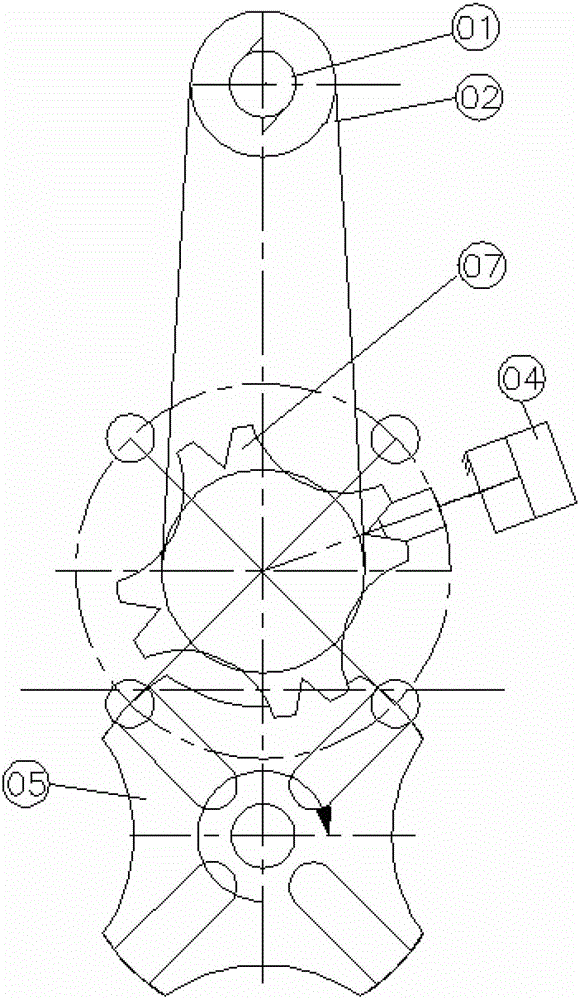

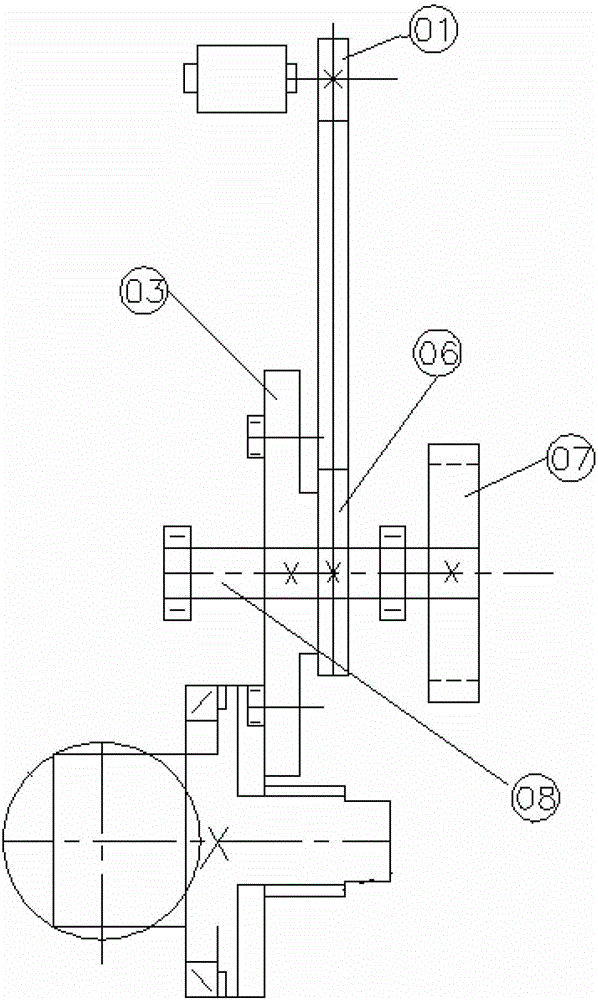

[0014] like figure 1 , 2 As shown, the present invention is a heavy-duty electric four-station wrist, including a motor and a chain transmission mechanism 2, the motor is in transmission connection with the driving sprocket 1 in the chain transmission mechanism 2, and the driven sprocket 1 in the chain transmission mechanism 2 The sprocket 6 is fixedly set on the index shaft 8, and the dial wheel 7 is also fixedly set on the index shaft 8, which also includes a sheave mechanism, and the active part 3 in the sheave mechanism is fixedly set on the above-mentioned index shaft 8 On the other hand, the follower 5 in the sheave mechanism is fixedly connected with the claw; wherein the dial 7 is cross-shaped, and positioning grooves are arranged at the four apexes of the dial 7, and are installed beside the dial 7. There is a pin cylinder 4 and the piston of the pin cylinder 4 points to the dial 7, so that the piston can be stretched out into the positioning groove on the dial 7 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com