Two-way positioning plug-in preform holder push mechanism

A technology of two-way positioning and pushing mechanism, applied in the field of bottle blowing machines, can solve problems such as inaccessibility of preforms, complex structure, and inability of preform holders to correspond to blowing molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

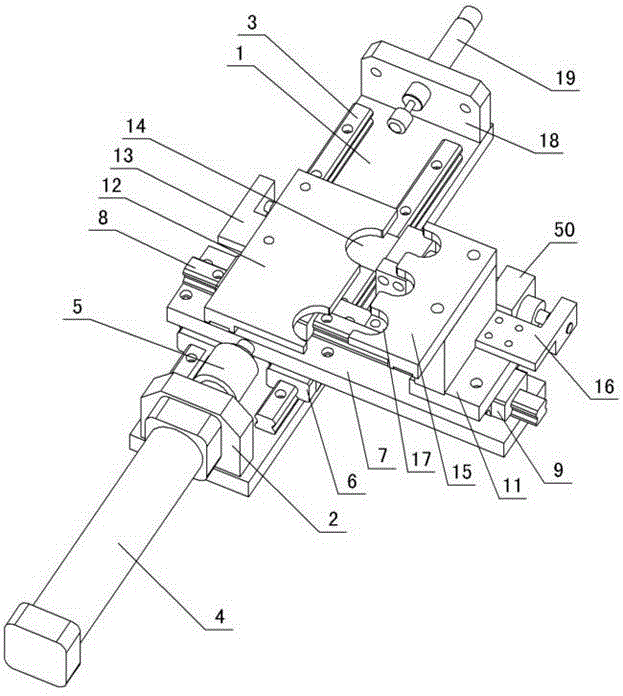

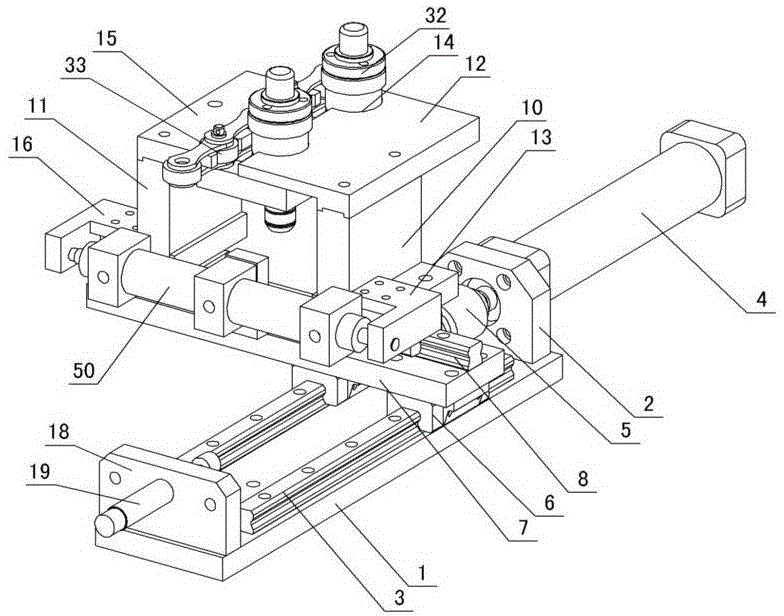

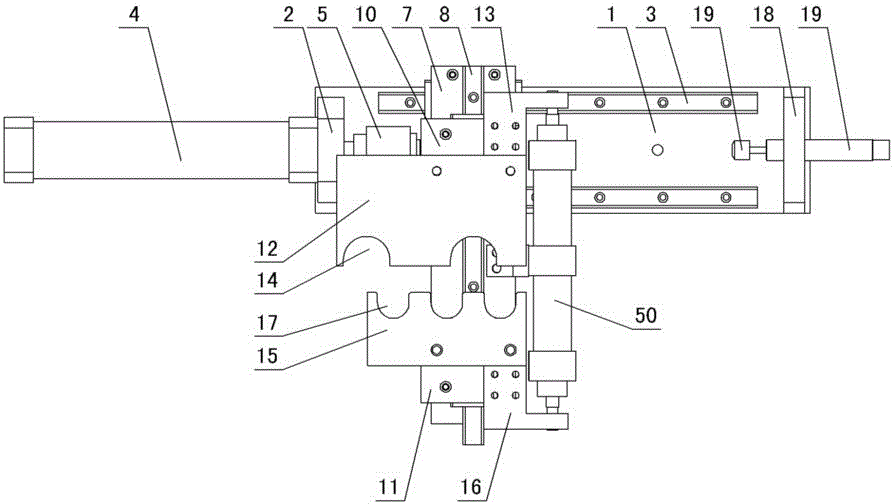

[0012] The invention relates to a two-way positioning plug-in type bottle base seat pushing mechanism, such as figure 1 — Figure 5 As shown, it is characterized in that: it includes a machine base, a stepping base plate 1 is arranged on the machine base, a cylinder fixing plate 2 and a left and right slide rail 3 are installed on the stepping base plate, and a push cylinder 4 is installed on one side of the cylinder fixing plate 2, and the push cylinder The piston rod is connected to the floating joint 5, and the left and right sliding blocks 6 are arranged on the left and right slide rails 3, and the left and right moving slide plates 7 are installed on the left and right moving slide blocks, and the left and right moving slide plates are connected with the floating joint 5, and the front and rear slide rails 8 are installed on the left and right moving slide plates , the front and rear moving sliders 9 are set on the front and rear slide rails, the front and rear slides 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com