Tire hand grab

A technology of tires and brackets, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems that affect safety production, personnel burns, low work efficiency, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

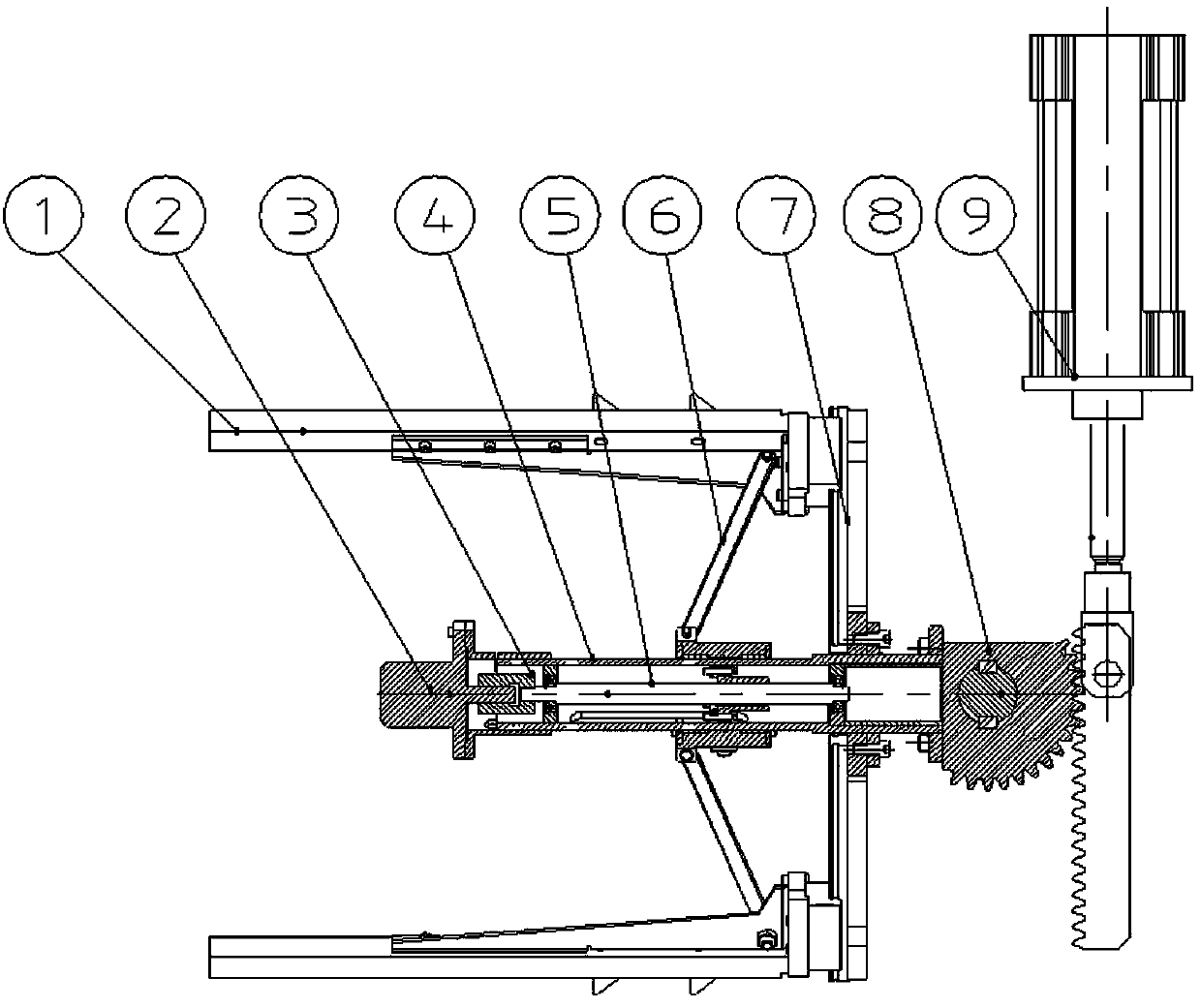

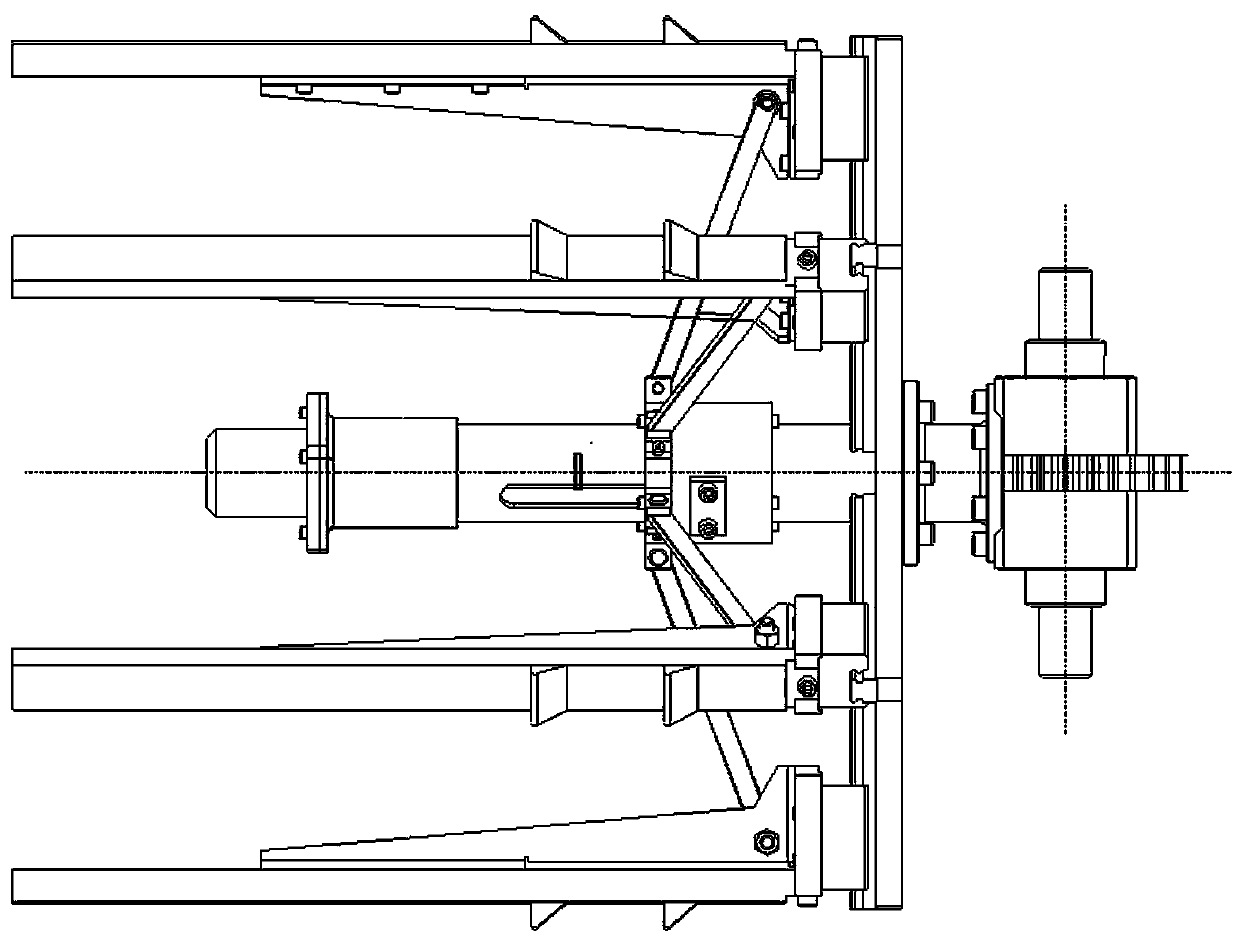

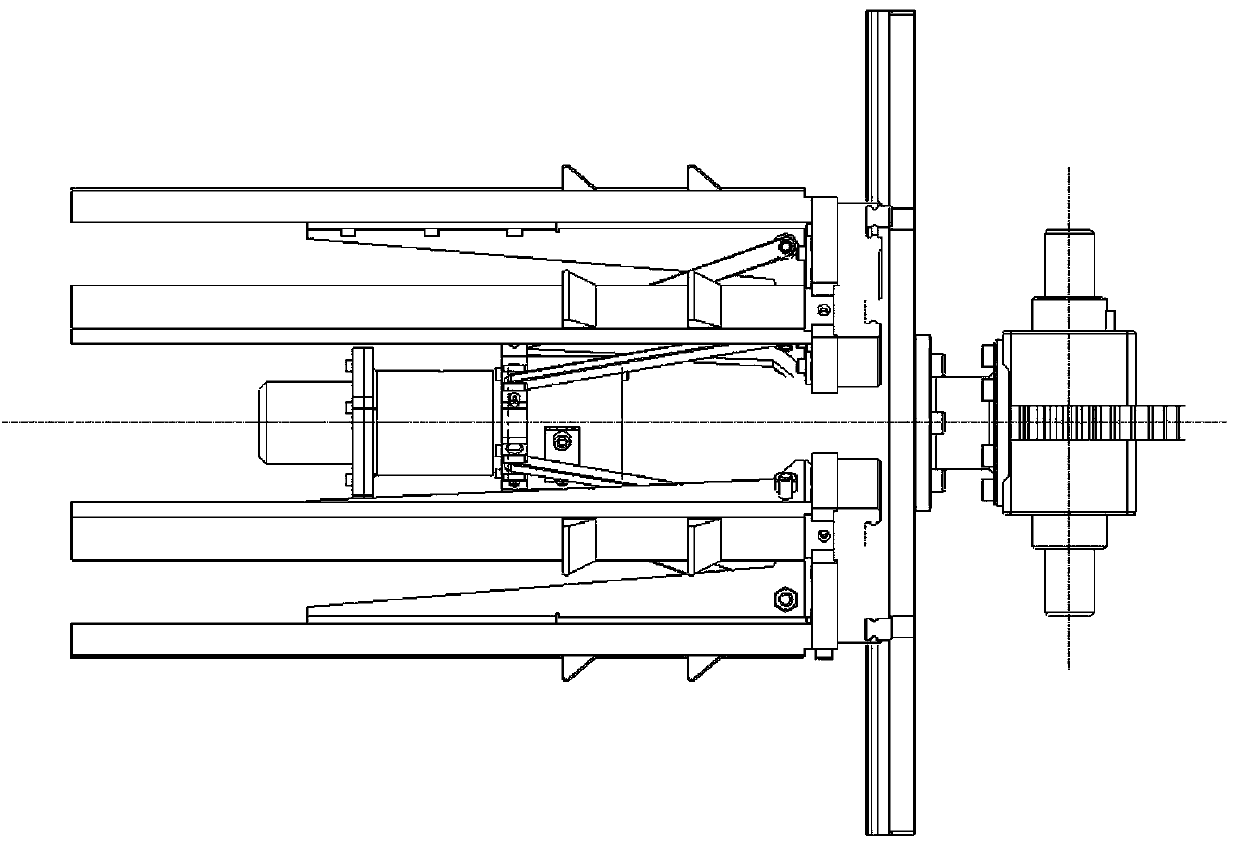

[0024] See figure 1 . The tire gripper consists of a tire bracket 1, a screw nut mechanism driving device 2, a coupling 3, a main shaft 4, a screw nut mechanism 5, a connecting rod 6, a tray 7, a rack and pinion mechanism 8 and a rack driving device 9 composition.

[0025] There are 6 tire brackets 1, which are evenly distributed on the tray 7, and are radially slidingly connected with the tray 7 through linear motion guide rails.

[0026] One end of the connecting rod 6 is movably connected to the position of the tire bracket 1 close to the pallet 7, and the other end is movably connected to the screw nut mechanism 5, and the screw nut mechanism 5 located in the main shaft 4 is connected to the driving device 2 through the coupling 3, The rack and pinion mechanism 8 is arranged at the end where the main shaft 4 passes through the tray 7, and is fixedly connected with the main shaft through a flange or the like, and a quarter of the circumference of the gear is toothed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com