Supporting base of fishbelly girder purlin

A technology for supporting bases and fish-belly beams, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems that parts cannot be interchanged and used universally, there is no standard connection size, and cannot be used as a combined structure, etc., to achieve convenient construction, The effect of saving construction space and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

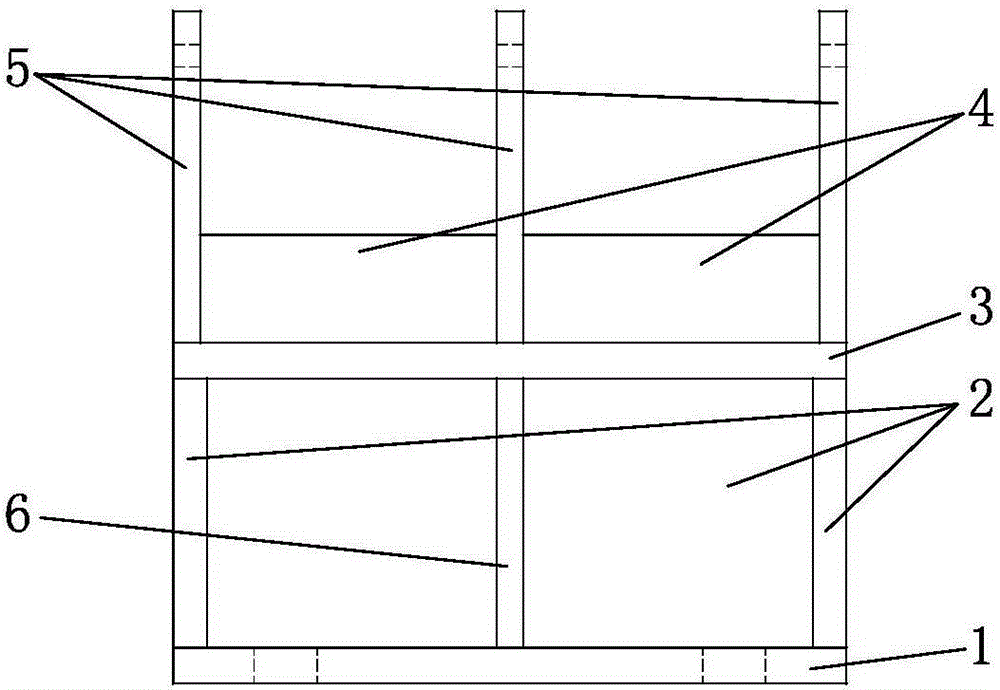

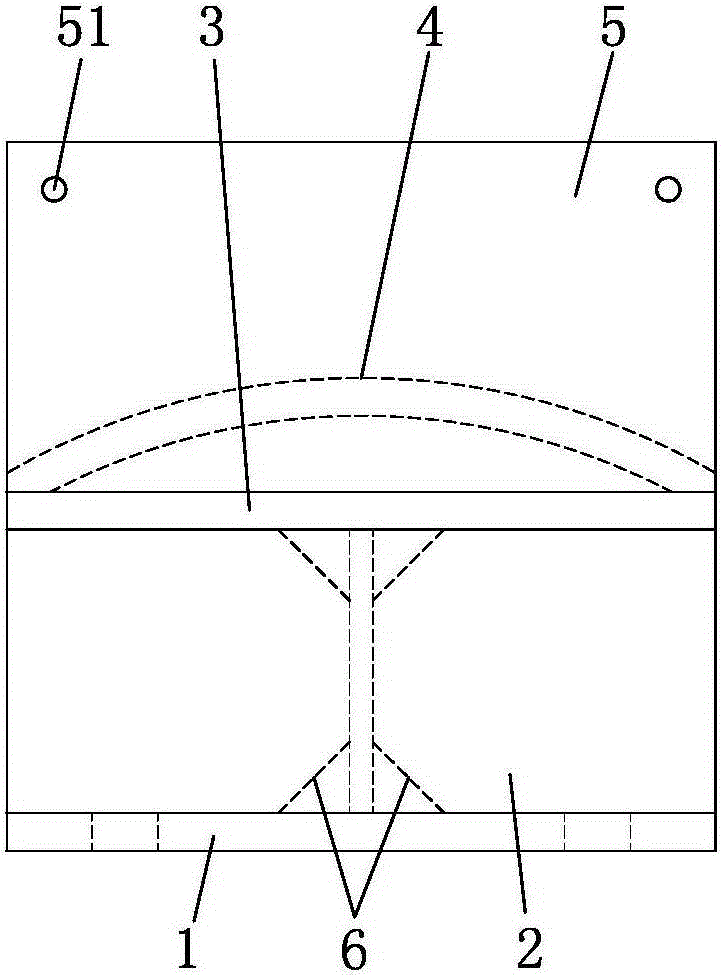

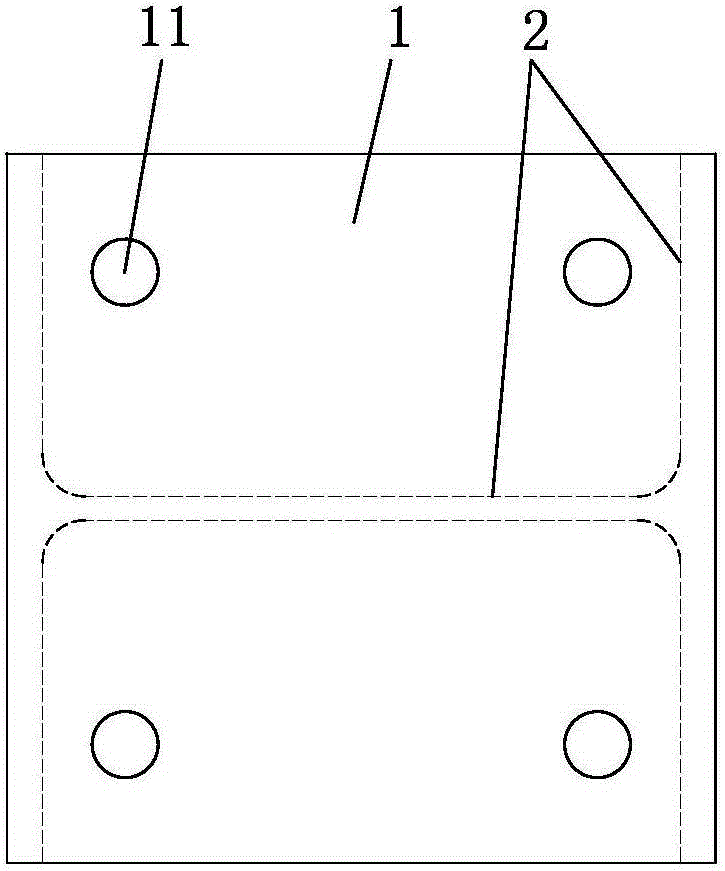

[0012] Such as figure 1 The supporting base of the fish-belly girder purlin shown includes a wide flange H-shaped steel 2 with a length of 100-150mm. There are four flange holes 11 on the top, and the four flange holes 11 are distributed at the four corners of a square. The side length of the square is 200mm, and the diameter of the flange holes 11 is 28mm. Thick square connecting plate 3, a 16mm thick reinforcing plate 6 is provided in the grooves on both sides of the H-shaped steel 2, the reinforcing plate 6 is perpendicular to the web of the H-shaped steel 2 and parallel to the wing plates on both sides of the H-shaped steel 2, the reinforcing plate The three sides of 6 are respectively welded and fixed with the square bottom plate 1, the square connecting plate 3 and the web of the H-shaped steel 2. The square connecting plate 3 is welded and fixed with three parallel guide plates 5, and the three guide plates 5 are connected with the square connecting plate. 3 is vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com