Shield sludge cleansing/recycling/reusing system and method

A technology of shield tunneling and sludge, which is applied in the field of purification, recycling and reuse of shield tunneling sludge, can solve the problems of difficult processing and high construction costs, and achieve the effects of saving consumption, saving processing costs, and reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

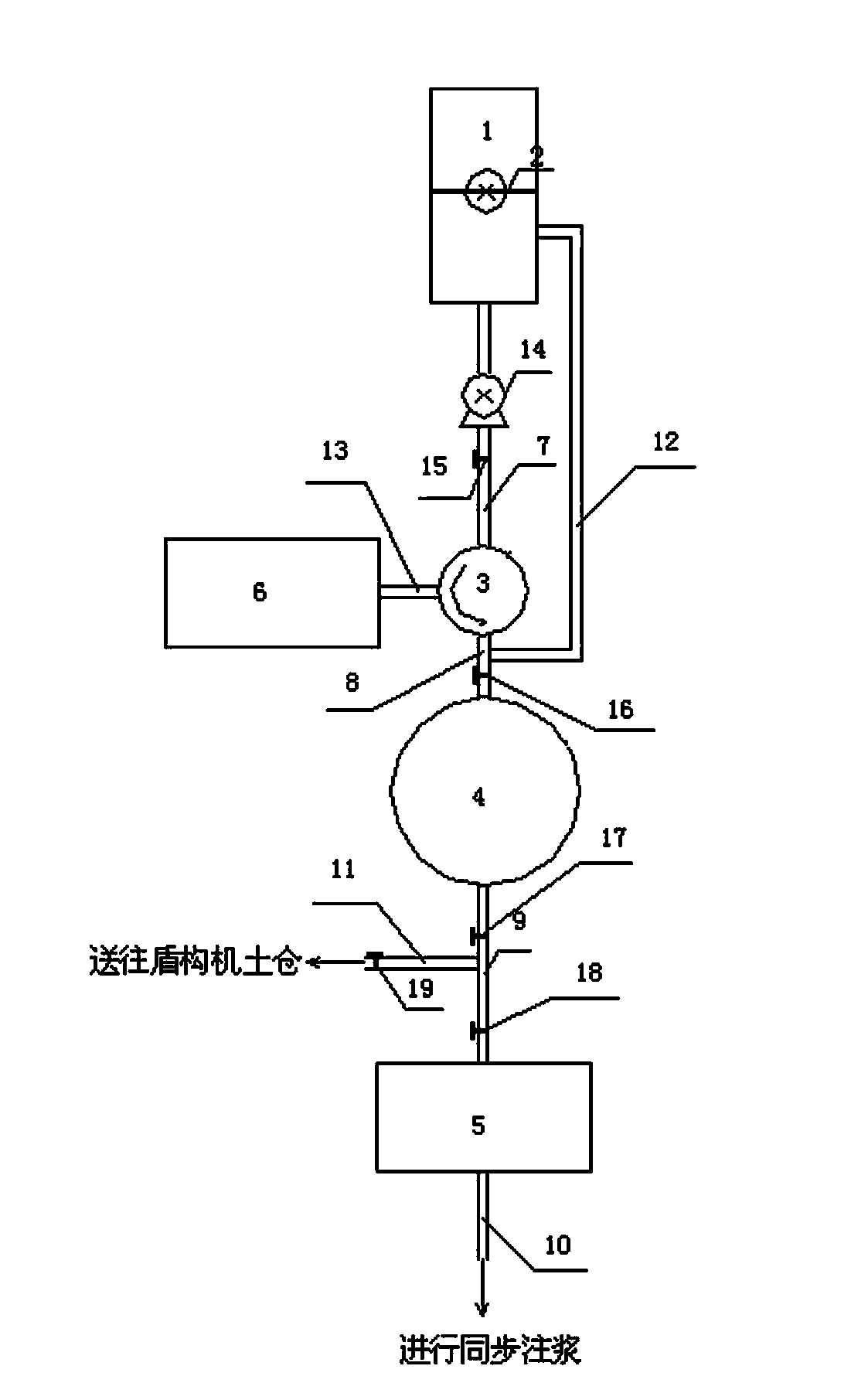

[0035] See attached figure 1 , Shield mud purification and recycling are reused in the synchronous grouting construction system, including a mud mixing tank 1 located near the ground slag bin of the shield tunnel 1, a mixer 2 located in the mud mixing tank; a mud pump located near the slurry mixing tank 14. Cyclone desander 3 installed near the mud pump, storage tank 4 installed at the synchronous grouting mortar mixing station of the shield, synchronous grouting mortar mixing station 5, connecting the slurry pipelines and installed at each The valve.

[0036] The implementation steps are as follows:

[0037] Step 1: Excavate a foundation pit with a length of not less than 10×5m and a depth of not less than 2m near the shield slag bin as a mud mixing tank 1;

[0038] Step 2: The gantry crane lifts the shield mud from the tunnel trolley and pours it into the mud mixing tank 1;

[0039] Step 3: Pour water into the mud pool and start the mud mixer 2 for mixing. After testing, the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com