Analysis method for fatigue crack propagation based on magnesium alloy electron beam welded sample

A fatigue crack propagation and electron beam welding technology, applied in the direction of analyzing materials, using sonic emission technology for material analysis, instruments, etc., can solve the problems of consuming test materials, long test cycles, etc., to achieve simple test process, simplify the test process, Work-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with specific embodiments.

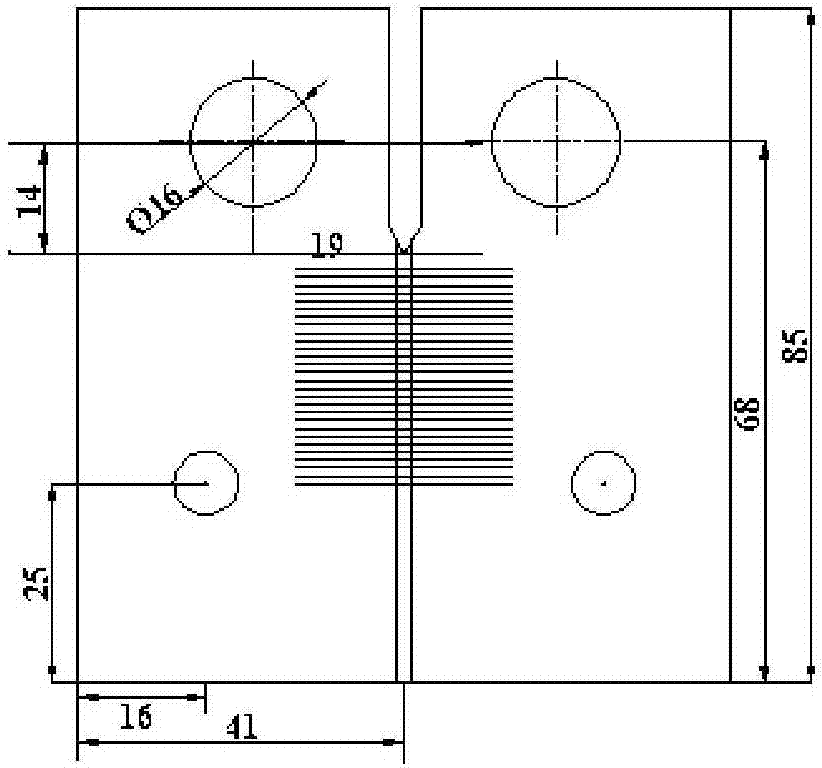

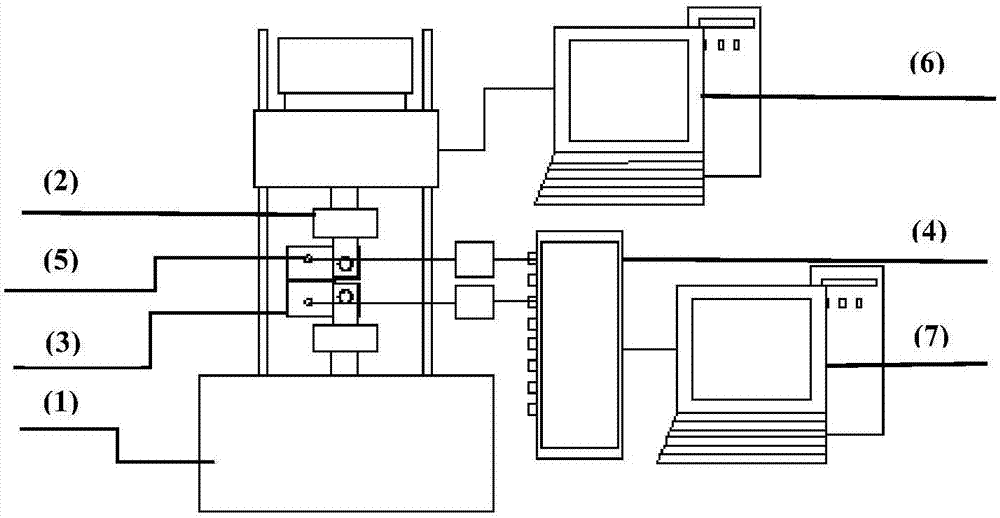

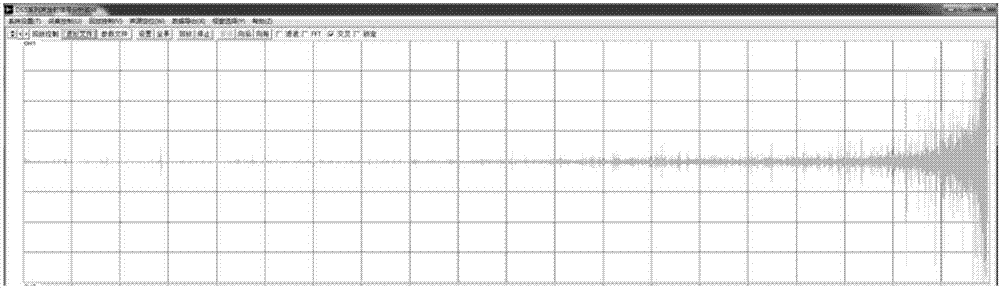

[0039] The material that the present invention adopts is the AZ31B magnesium alloy of commercial 10mm thick extrusion molding, and test piece size is as follows figure 1As shown, the wire cutting method is used to process along the direction perpendicular to the extrusion; after the processing is completed, the surface of the test piece is polished with 800 mesh, 1000 mesh and 1500 mesh metallographic sandpaper in order to make the surface and the wire cutting surface smooth. Roughness up to R a =0.32-0.63μm; the surface of the test piece starts from the prefabricated crack, and draws 30 parallel lines with an interval of 1mm perpendicular to the crack propagation direction to observe the crack propagation length; the fatigue test equipment is a low-frequency tension-compression fatigue crack growth test machine. The fatigue load is a pull-pull load, the cyclic characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com