Zero-torque anchor rod pre-tightening machine tool

A zero-torque, bolt technology, applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problem of increasing the composite stress concentration of the bolt thread, the fracture and damage of the bolt under high torque, and the increase of the pre-tightening force of the bolt. The effect is not obvious and other problems, so as to achieve the effect of improving the pre-tightening force of the bolt, reducing the damage of the thread, and preventing the uneven force of the support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

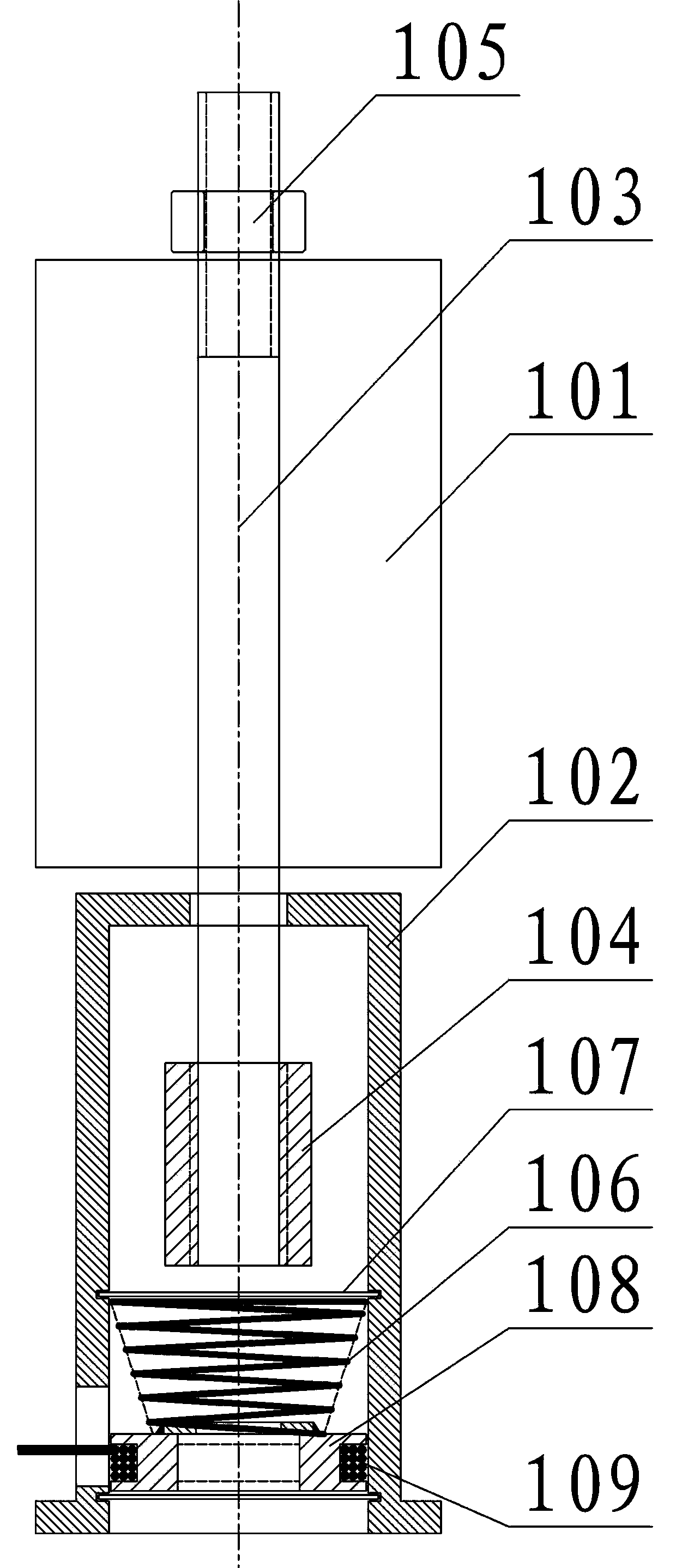

[0050]The rope fastening nut structure of the zero-torque bolt pretensioning tool is composed of a conical spring 106, a positioning circlip 107, a rope-wrapped structure fastening nut disk 108 and a rope 109, and the rope 109 is used to pull the rope-wrapped structure The tightening nut disc 108 tightens the anchor nut, and the tightening nut disc 108 with the rope 109 pulled to tighten the anchor nut.

Embodiment approach 2

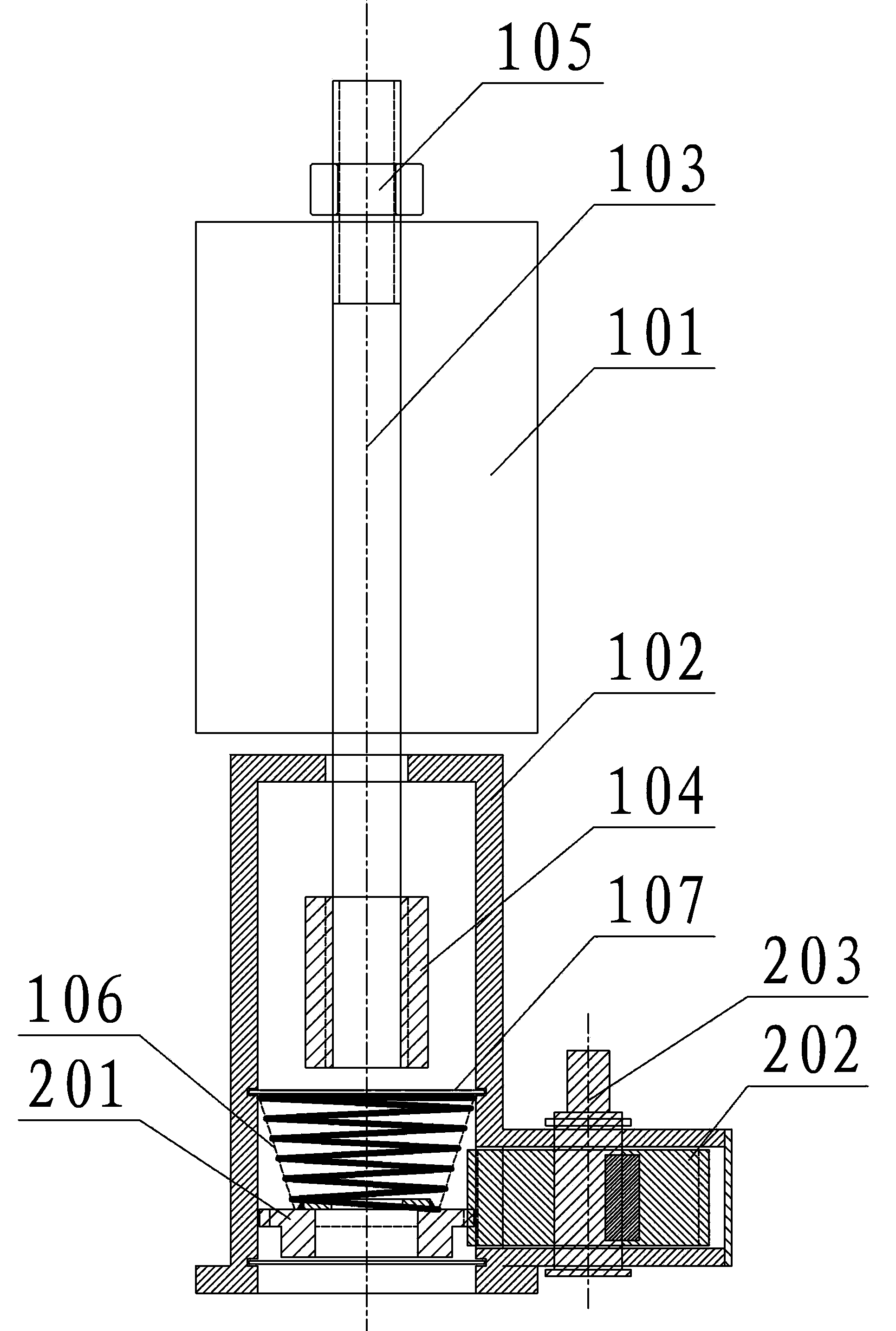

[0052] The gear transmission fastening nut structure of the zero-torque bolt pre-tightening machine is composed of a conical spring 106, a positioning circlip 107, a gear structure fastening nut plate 201, a transmission gear 202, a fixed pin shaft 203 and a ratchet wrench. , using the gear transmission to drive the gear structure fastening nut plate 201 to fasten the anchor nut. The above-mentioned gear transmission can be a conical bevel gear, a rack transmission or a ratchet transmission, etc.

Embodiment approach 3

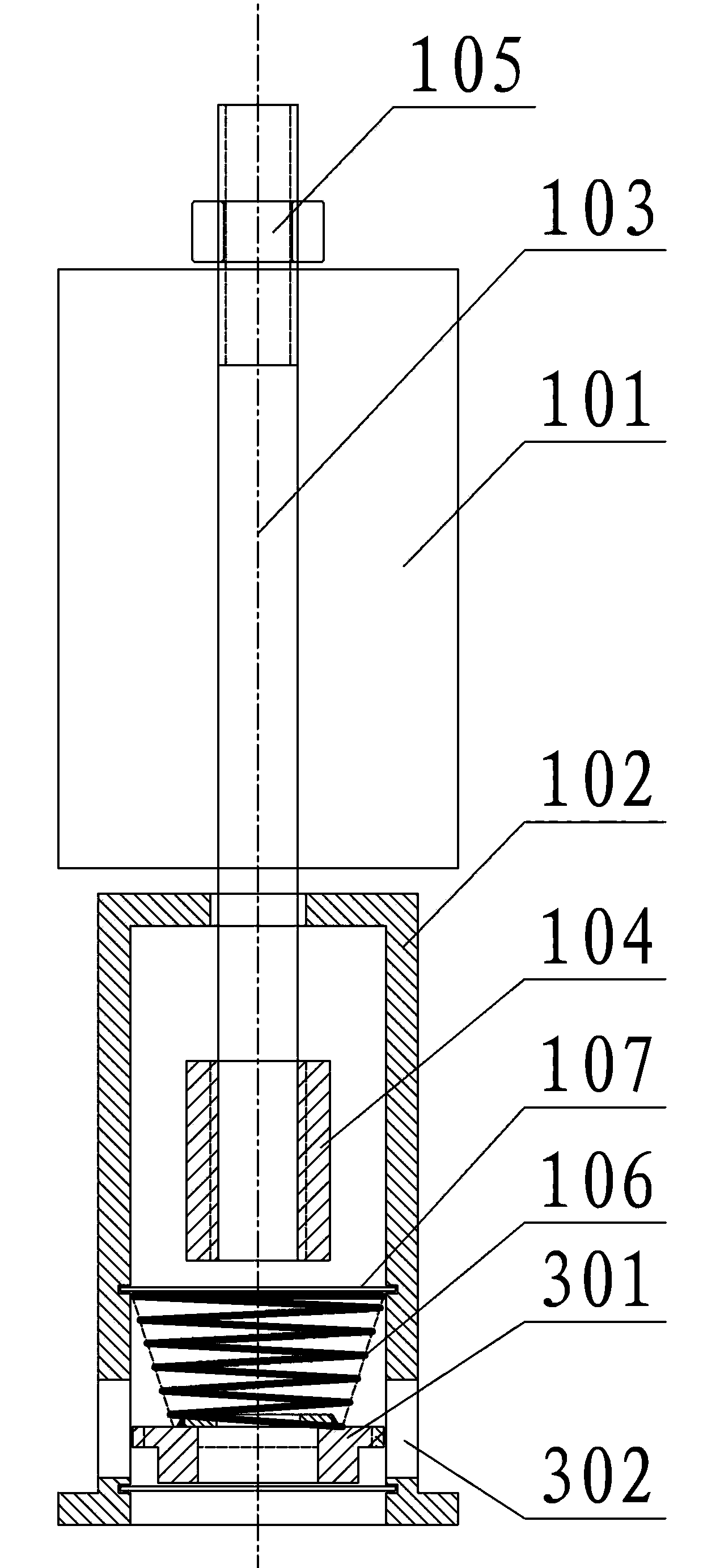

[0054] The manual fastening nut structure of the zero-torque bolt pre-tightening tool is composed of a conical spring 106, a positioning circlip 107, a fastening nut plate 301 and a dial window 302, which is manually moved from the dial window 302 The fastening nut plate 301 fastens the anchor nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com