Tracked Adaptive Pipeline Crawler

A pipeline crawler, self-adaptive technology, applied in the direction of special pipes, pipe elements, pipes/pipe joints/fittings, etc., can solve the problems of inability to overcome the crawling of curved pipes, inconsistent inner and outer speeds, and inability to adapt to cable laying, etc. Control, adjust and correct the crawling posture, realize the crawling posture, and ensure the effect of driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

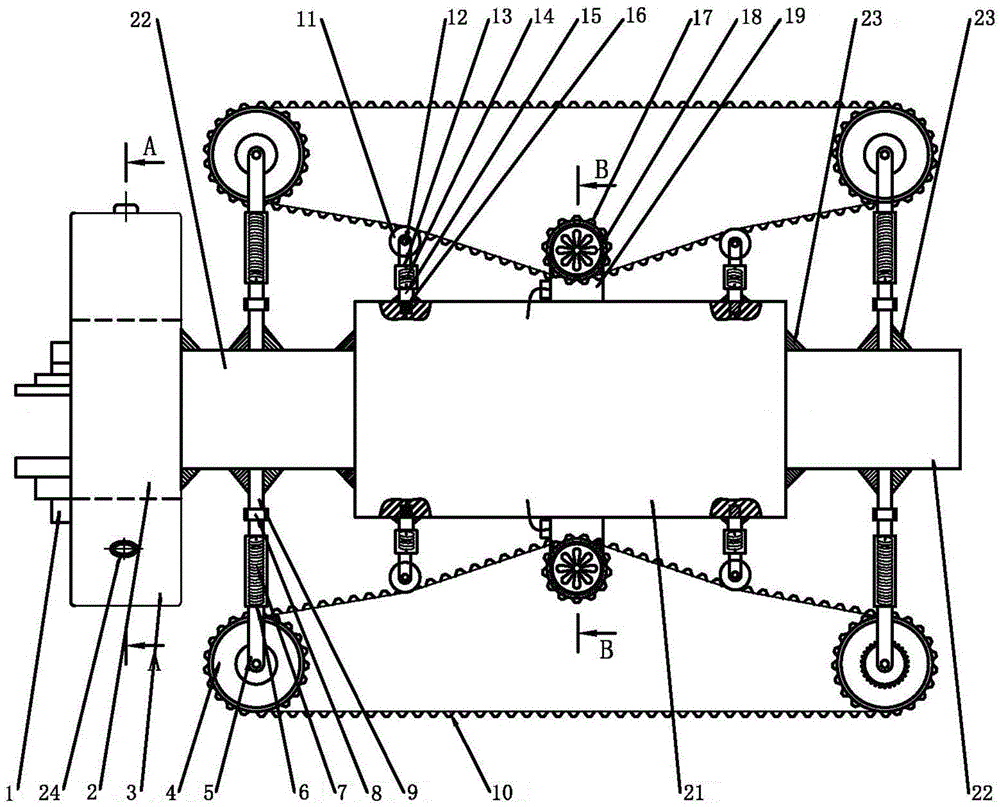

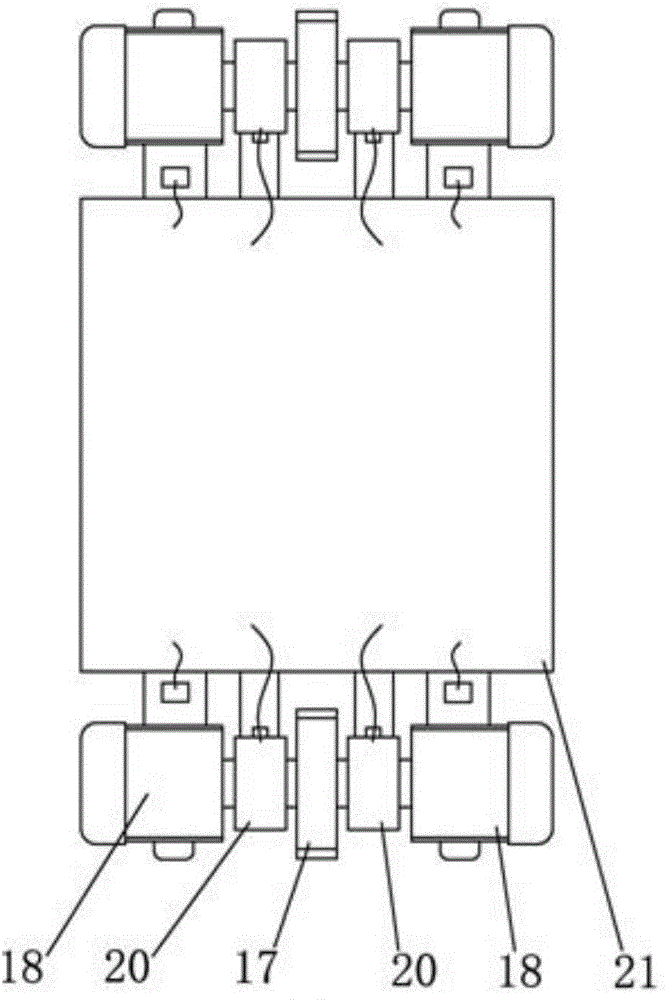

[0022] The structure of the crawler-type adaptive pipeline crawler of the present invention includes a clamping unit, a crawling unit and a control unit.

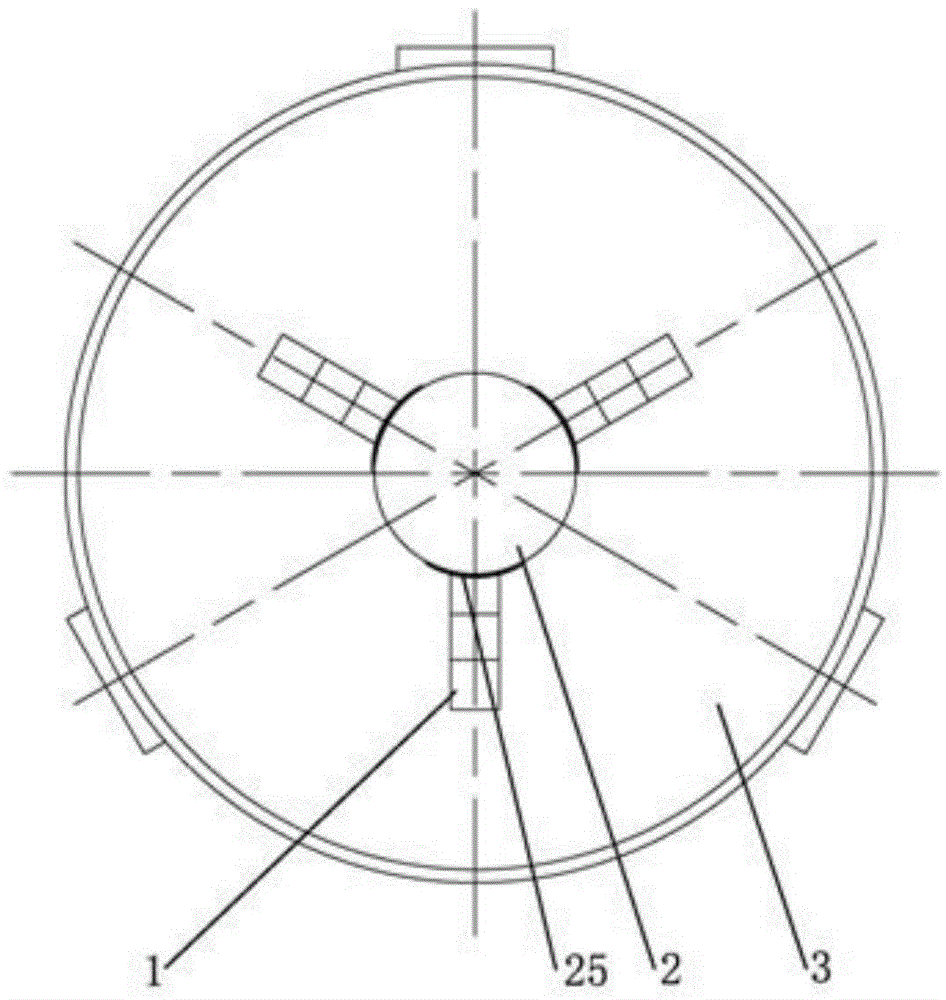

[0023] like figure 1 , figure 2 As shown, the structure of the clamping unit includes a chuck body 3, the through hole of the shaft center of the chuck body 3 is called the middle wire hole 2, and the front end surface of the chuck body 3 is installed with three sets of jaws 1 centripetally, The inner circular surfaces of the three groups of jaws 1 together form an arc-shaped clamping seat 25 , each group of jaws 1 is provided with a countersunk head adjusting bolt 24 , and the three groups of jaws 1 are provided with a jaw drive mechanism.

[0024] The structure and principle of the clamping unit are similar to the three-jaw chuck on the machine tool. The centripetal position of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com