Solar inner wall lens type compound parabolic concentrator with air interlayer

A compound paraboloid and air interlayer technology, which is applied in the field of solar energy utilization, can solve the problems of uneven light intensity distribution of concentrators and rising tracking costs, and achieve the effects of improving light intensity distribution, high geometric concentration ratio, and improving optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

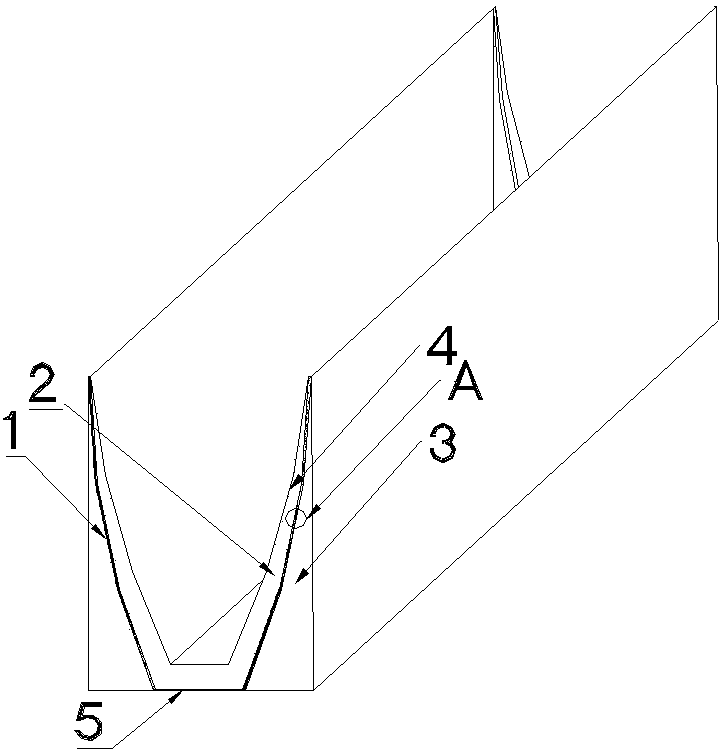

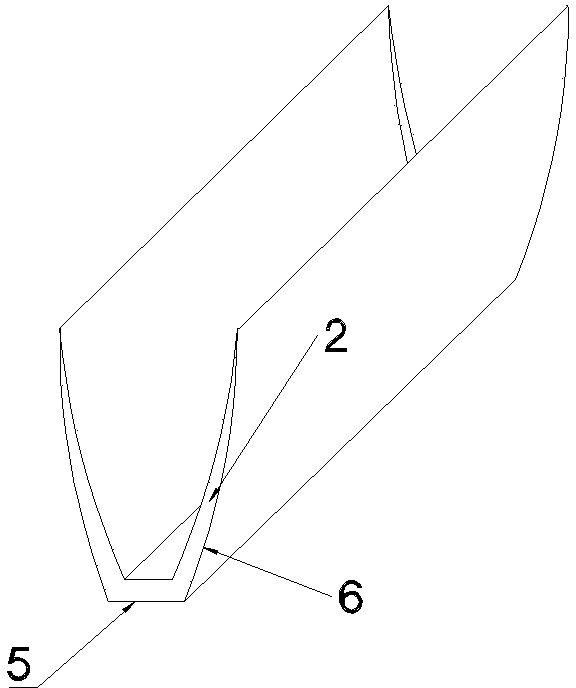

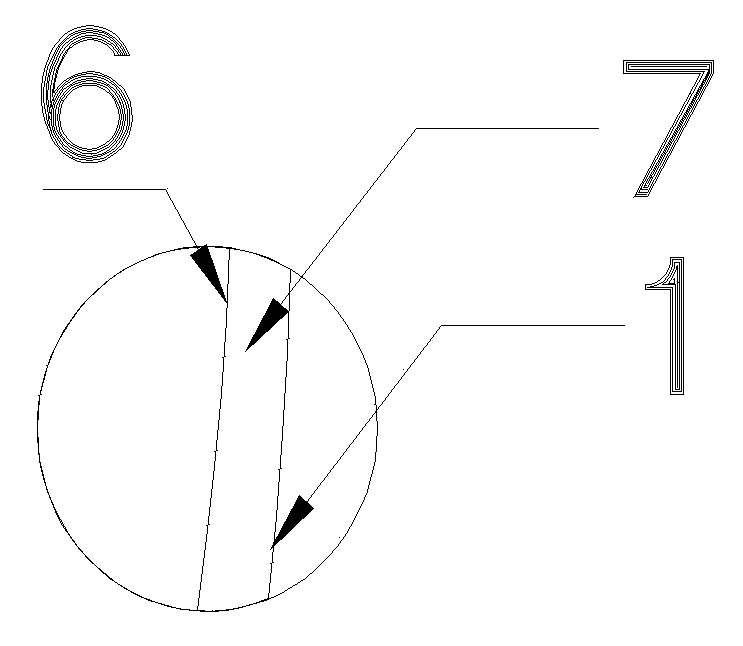

[0020] see figure 1 , the solar inner wall lens-type compound parabolic concentrator with an air interlayer includes a U-shaped compound parabolic concentrator as a whole, and the compound parabolic concentrator includes a frame 3 with a U-shaped cross section, and two compound parabolic reflectors 1 are respectively symmetrical Located on both sides of the frame 3; a lens 2 with a U cross section is installed between two compound parabolic reflectors 1. see figure 2 , taking the apex of the outer curved surface 6 as a fixed point, and rotating the outer curved surface 6 clockwise at an angle of 3 degrees around the fixed point to obtain the inner curved surface 4 . The thickness between the inner curved surface 4 and the outer curved surface 6 of the side walls on both sides of the lens 2 gradually increases from top to bottom, and the outer curved surfaces 6 of the side walls on both sides of the lens 2 match with the compound parabolic reflectors 1 on both sides respectiv...

Embodiment 2

[0024] Taking the apex of the outer curved surface 6 as a fixed point, the outer curved surface 6 is rotated clockwise by 5 degrees around the fixed point to obtain the inner curved surface 4 . The air interlayer 7 has a thickness of 0.5 mm.

[0025] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com