Optical fiber collimator

A technology of optical fiber collimator and optical fiber, which is applied in the coupling direction of optical waveguide, can solve the problems of low light absorption rate, huge data volume, and low optical coupling efficiency, and achieve simple assembly process, high optical coupling rate, and small volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

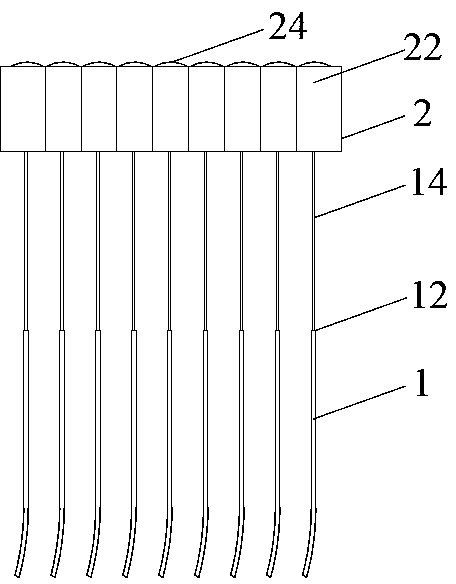

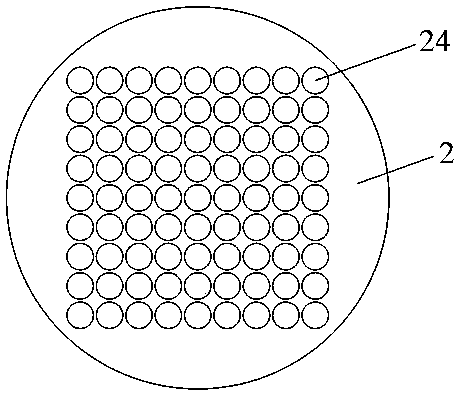

[0024] like figure 1 , figure 2 , Figure 5 As shown, the present invention proposes an optical fiber collimator, comprising 81 optical fibers 1 and 81 free-form surface self-focusing lenses 2, the optical fiber 1 is a quartz fiber, and the material of the free-form surface self-focusing lens 2 is optical molded glass , 81 free-form surface self-focusing lenses 2 are arranged in a 9×9 array and are integrated; the optical fiber 1 includes a coating layer 12 and a core 14, and one end of the core 14 is exposed on the coating Outside the layer 12; the free-form surface self-focusing lens 2 includes a cuboid part 22 and a free-form surface part 24, the free-form surface part 24 is a convex spherical surface, and the free-form surface part 24 is arranged on the center of the minimum surface of the cuboid part 22 position, the free-form surface part 24 is coated with a reflective film, the smallest surface of the cuboid part 22 is slightly larger than the free-form surface part ...

Embodiment 2

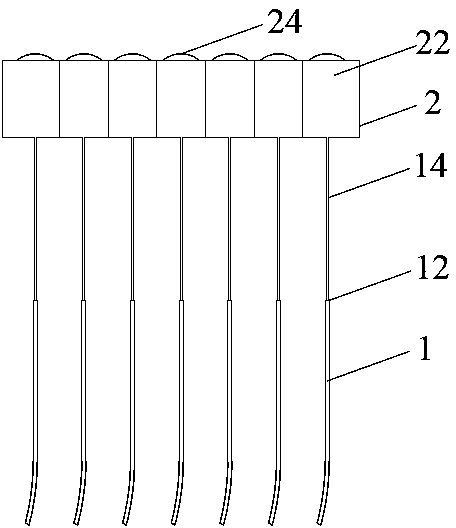

[0026] like image 3 , Figure 4 , Figure 5 As shown, the present invention proposes an optical fiber collimator, comprising 21 optical fibers 1 and 21 free-form surface self-focusing lenses 2, the optical fiber 1 is a glass optical fiber, and the material of the free-form surface self-focusing lens 2 is optical plastic. The 21 free-form surface self-focusing lenses 2 are arranged in a 7×3 array and are integrated; the optical fiber 1 includes a coating layer 12 and a core 14, and one end of the core 14 is exposed on the coating layer 12 outside; the free-form surface self-focusing lens 2 includes a cuboid part 22 and a free-form surface part 24, the free-form surface part 24 is an arc surface, and the free-form surface part 24 is arranged on the center of the minimum surface of the cuboid part 22 position, the free-form surface part 24 is coated with a reflective film, the smallest surface of the cuboid part 22 is slightly larger than the free-form surface part 24, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com