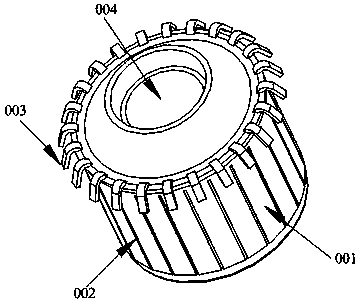

Automatic detection device for commutator

An automatic detection device and detection device technology, applied in the direction of measuring devices, instruments, manipulators, etc., can solve problems such as difficulty in ensuring consistency in inspection, difficulty in ensuring quality, and unstable quality, so as to reduce the number of manual movements and avoid inconsistent inspections. The effect of ensuring dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

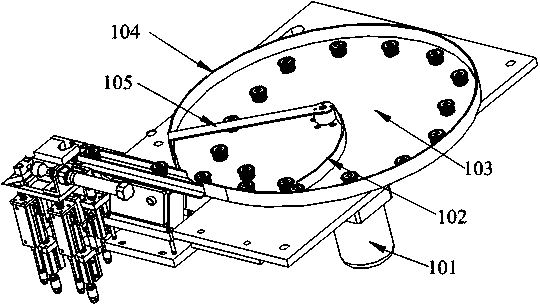

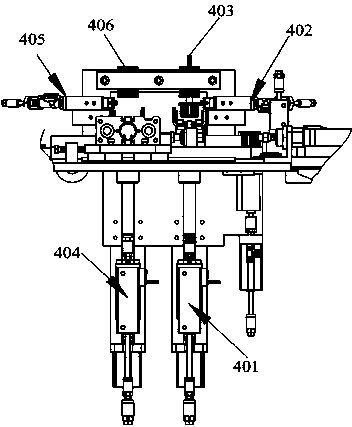

[0029] Such as figure 1 As shown, the commutator automatic detection device includes the machine table and the turntable arranged on the machine table in sequence 1, the inter-chip high-voltage test and high-voltage test device 4, the go-no-go gauge detection device 9, and the copper hook of the commutator is aligned with the slot The detection device 11, the discharge port of the turntable 1 is provided with a linear feeder 2, the discharge end of the linear feeder 2 is provided with a first manipulator 3, and the first manipulator 3 is opposite to the inter-chip high-voltage test and high-voltage test device 4 A high-voltage tester 5 is arranged above the inter-chip high-voltage test and high-voltage test device 4, a conveyor belt 7 is connected next to the inter-chip high-voltage test and high-voltage test device 4, and a second manipulator 8 is provided at the discharge end of the conveyor belt 7, The second manipulator 8 is opposite to the go-no-go gauge detection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com