Testing device for shear-resistant fatigue property of chemical anchoring stud

A fatigue performance and test device technology, applied in the direction of measuring devices, scientific instruments, strength characteristics, etc., can solve the problems of incomplete collection of mechanical performance parameters, poor universality and reusability of fixtures, and affecting the shear force of studs. Achieve the effects of ensuring pure shear stress state, improving recycling efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

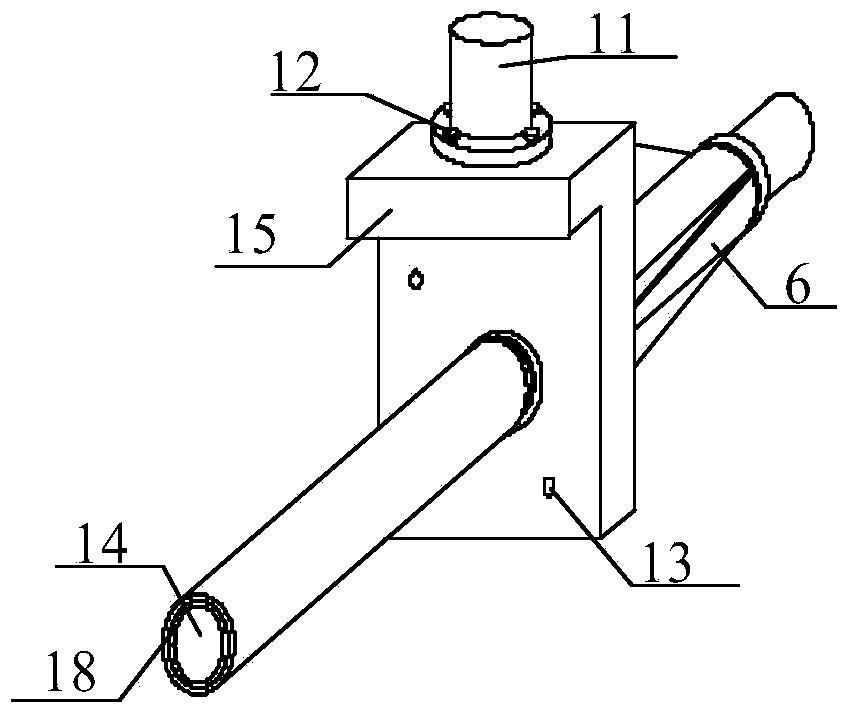

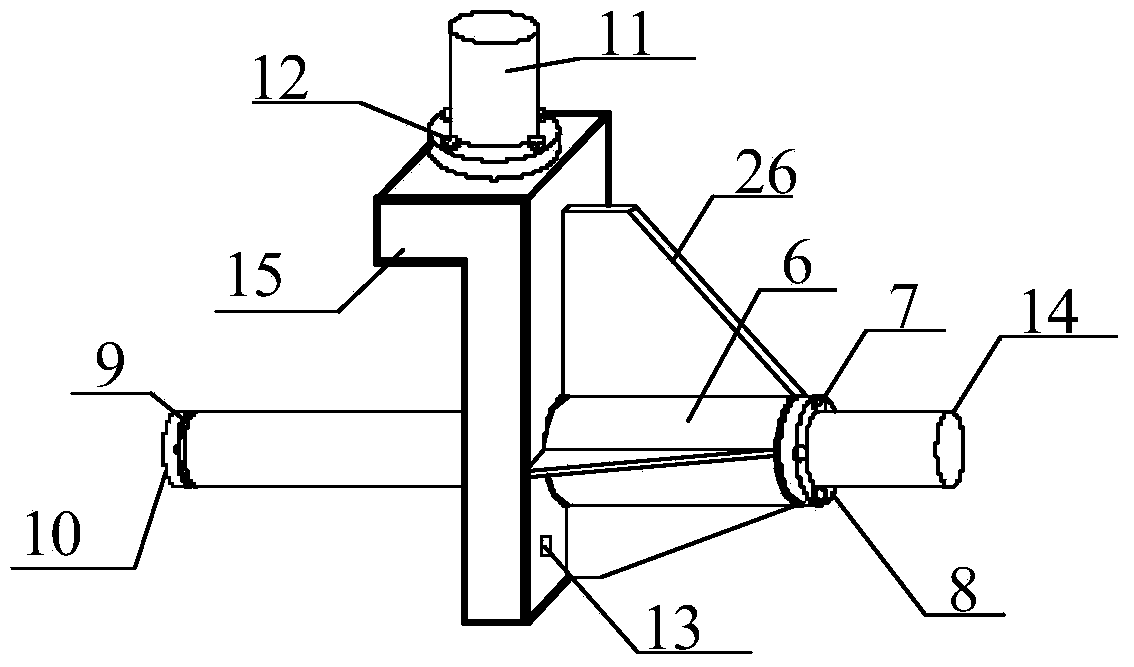

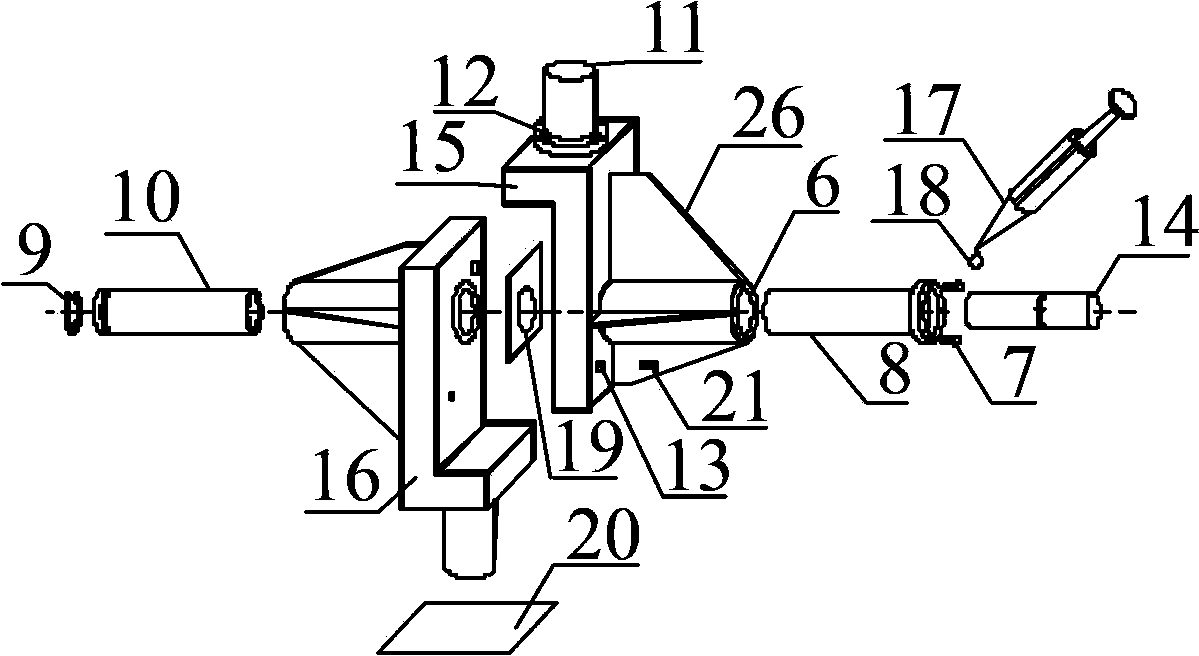

[0043] figure 1 It is a schematic diagram of an exploded structure of a chemical anchoring stud anti-shear fatigue performance test device of an embodiment of the invention; Figure 2-a , Figure 2-b Is the isometric drawing of the first fixture and the second fixture without a sleeve stiffening plate; Figure 2-c , Figure 2-d It is a isometric view of the first clamp and the second clamp with sleeve stiffening plate; Figure 3-a , Figure 3-b , Figure 3-c Is a schematic diagram of the first clamp and the second clamp after being assembled; Figure 4 It is an axonometric drawing with a circlip sleeve; Figure 5-a , Figure 5-b Is a T-sleeve isometric drawing; Figure 6-a , Figure 6-b , Figure 6-c , Figure 6-d , Figure 6-e , Figure 6-f , Figure 6-g , Figure 6-h , Figure 6-i It is a schematic diagram of the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com