Classification method for film defects

A classification method and a technology for thin film defects, which are applied in the direction of optical testing for flaws/defects, etc., can solve the problems of low detection efficiency, manpower and material resources, etc., and achieve the effects of improving accuracy, eliminating interference, and saving detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

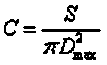

[0040] The film defect classification method includes an image preprocessing part and a detection part. The image preprocessing part includes (1) extracting a target area and (2) eliminating false boundaries; the detection part includes (3) defect classification detection.

[0041] Below in conjunction with accompanying drawing, these two parts are described:

[0042] Such as figure 1 shown

[0043] (1) Extract the target area

[0044] In addition to the complete product image, the image to be inspected by the high-speed linear array CCD camera also contains background areas with high-brightness grayscale features on both sides, such as figure 2 As shown, the white background area on both sides. According to the gray features of the background and foreground, an appropriate global threshold is selected to separate the background and obtain the target image. Since the gray feature of the perforated area is consistent with the background, the perforated area is also elimina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com