Olfactory analog instrument-oriented gas sensor selection, replacement and correction method

A technology of a gas sensor and a calibration method, applied in the field of gas sensor selection, replacement and calibration for olfactory analog instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

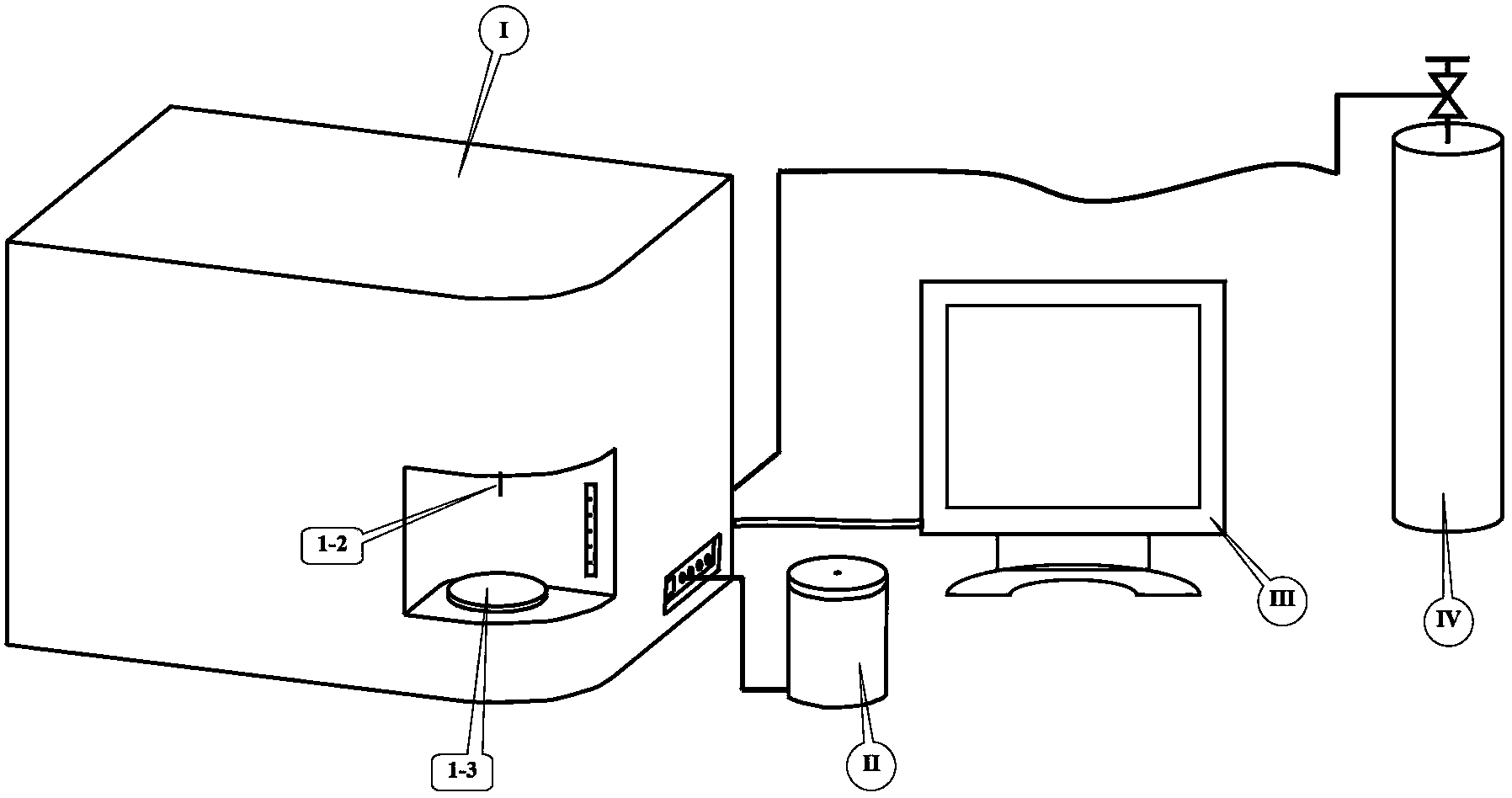

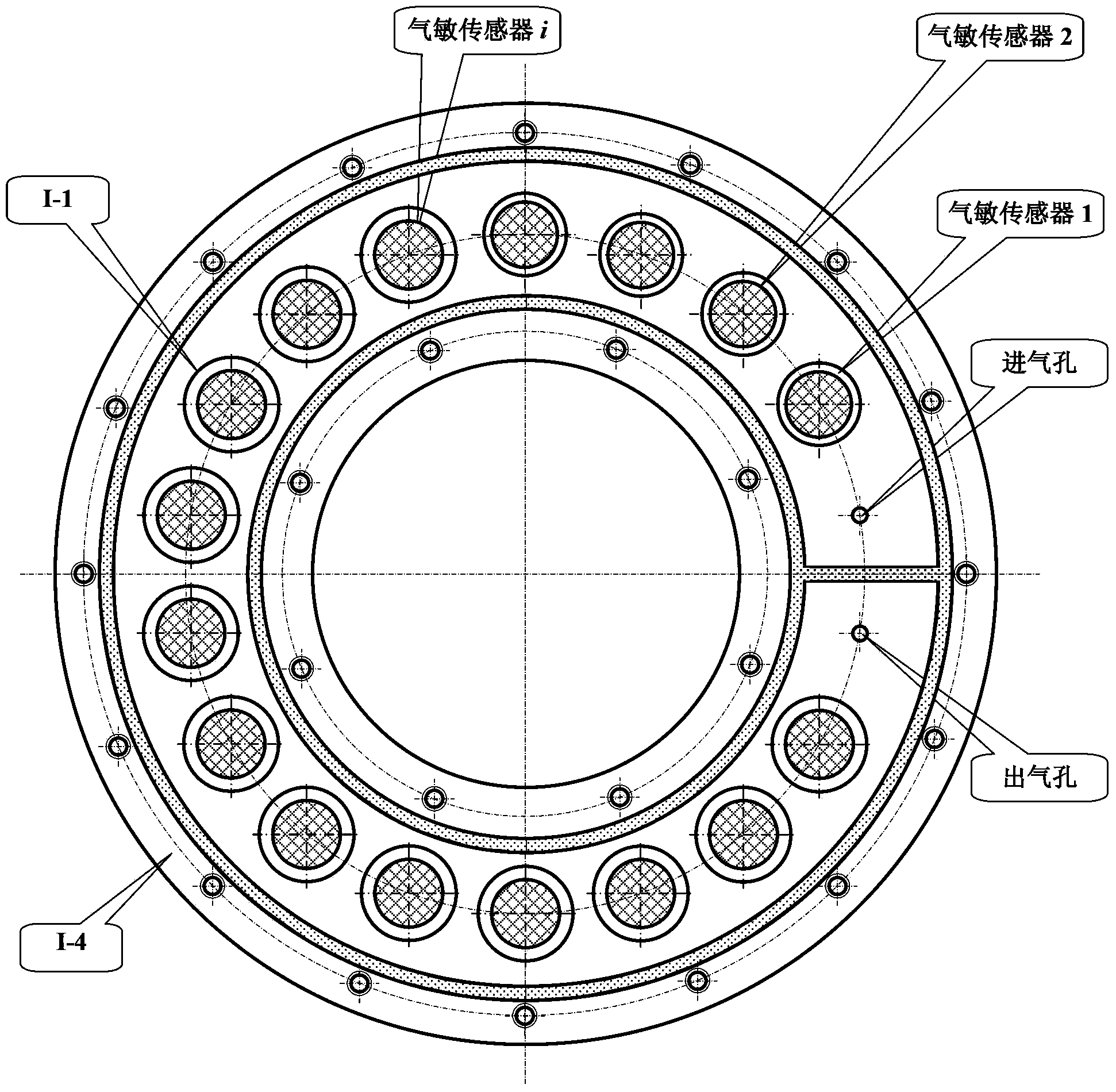

[0052] figure 1 It is a schematic diagram of the constituent units of the olfactory simulating instrument when no sampling is performed in the present invention—a method for selecting, replacing and calibrating a gas sensor oriented to an olfactory simulating instrument. Its characteristics are that it includes test box I, headspace volatile gas generator II, monitor III, and clean air bottle IV; test box I and headspace volatile gas generator II are connected by 6-core cables, of which 2 cores are power lines, The 4 cores are signal transmission lines; the test box I is connected to the clean air bottle IV through a gas pipeline; the test box I is connected to the display III through a cable. The injection needle I-2 of the test box and the support disc I-3 of the autosampler lifting unit are visible from the outside.

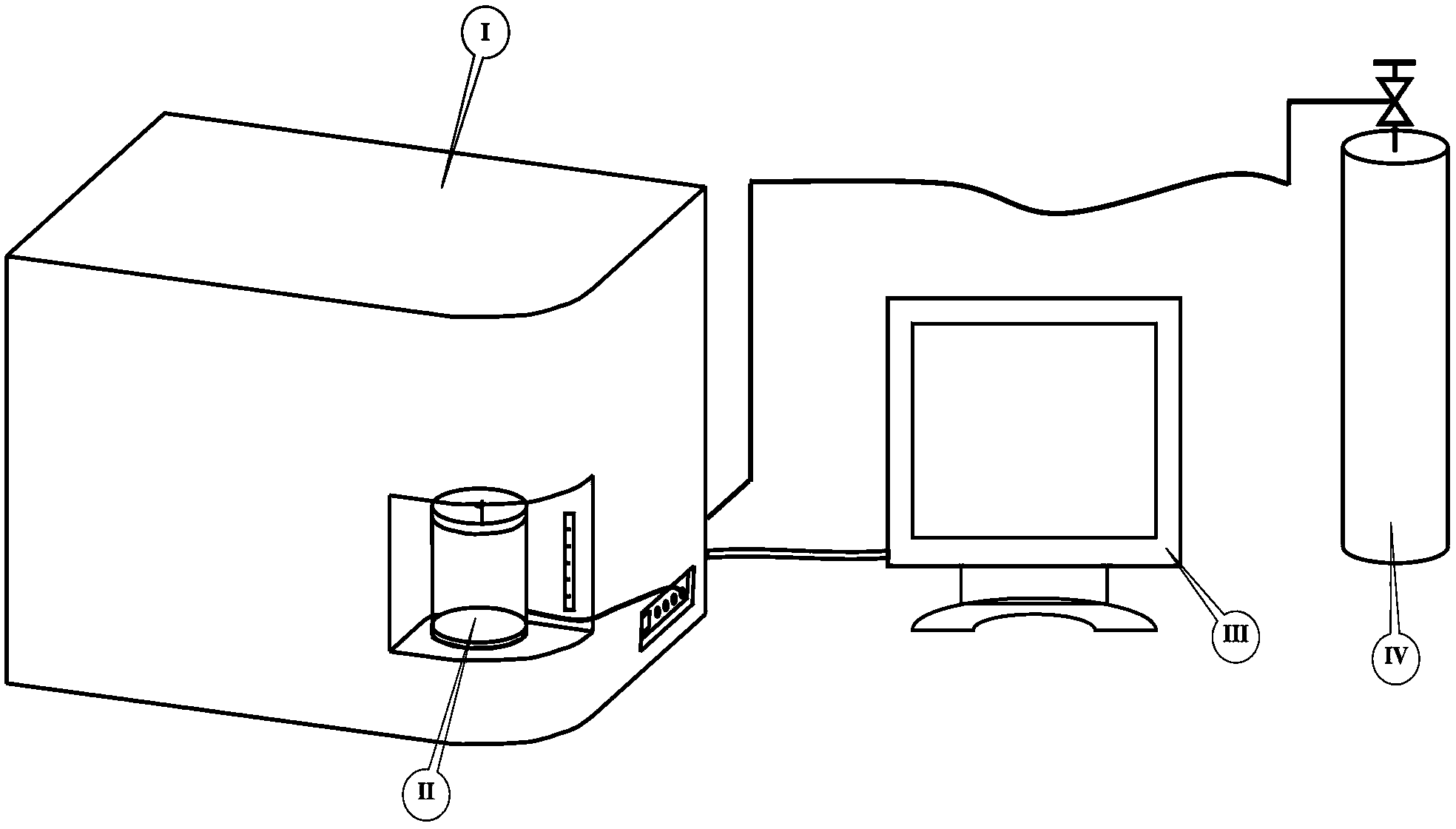

[0053] The components of the test b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com