Wing-spar structural topology optimization method based on stress constraint

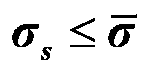

A technology of topology optimization and stress constraint, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of large tangential stress on nails, reduce tangential stress, ensure structural stiffness performance, and avoid stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

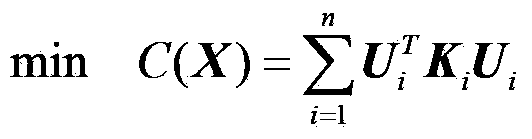

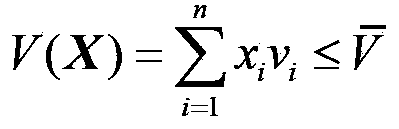

[0024] The stress constraint-based topology optimization method of the wing spar structure of the present invention specifically includes the following steps.

[0025] The present invention is illustrated by taking the topological optimization design of a cantilever beam with a skin considering nail loading as an example. The thickness of the cantilever beam is 40mm, the length is 1000mm, and the height is 250mm. The cantilever beam is connected to the non-design domain beam by 7 bolts. The thickness of the non-design domain beam is 40mm, the length is 1000mm, and the height is 37.5mm. The length of the bolt is 10, and the section is a square of 20×20. Young's modulus E=2.63GP, Poisson's ratio μ=0.1. A concentrated load P=60N is applied to one end of the cantilever beam, and the direction is upward.

[0026] (a) Establish a topology optimization model, define the cantilever beam as the design domain Ω of topology optimization, and discretize Ω into 9600 3-dimensional unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com