Passive water supplementation spraying system of spent fuel pool

A technology for spent fuel pools and spray systems, applied in the field of passive water replenishment spray systems for spent fuel pools, which can solve problems such as endangering public safety, exposed spent fuel components, and failure to ensure normal cooling of spent fuel pools, thereby improving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

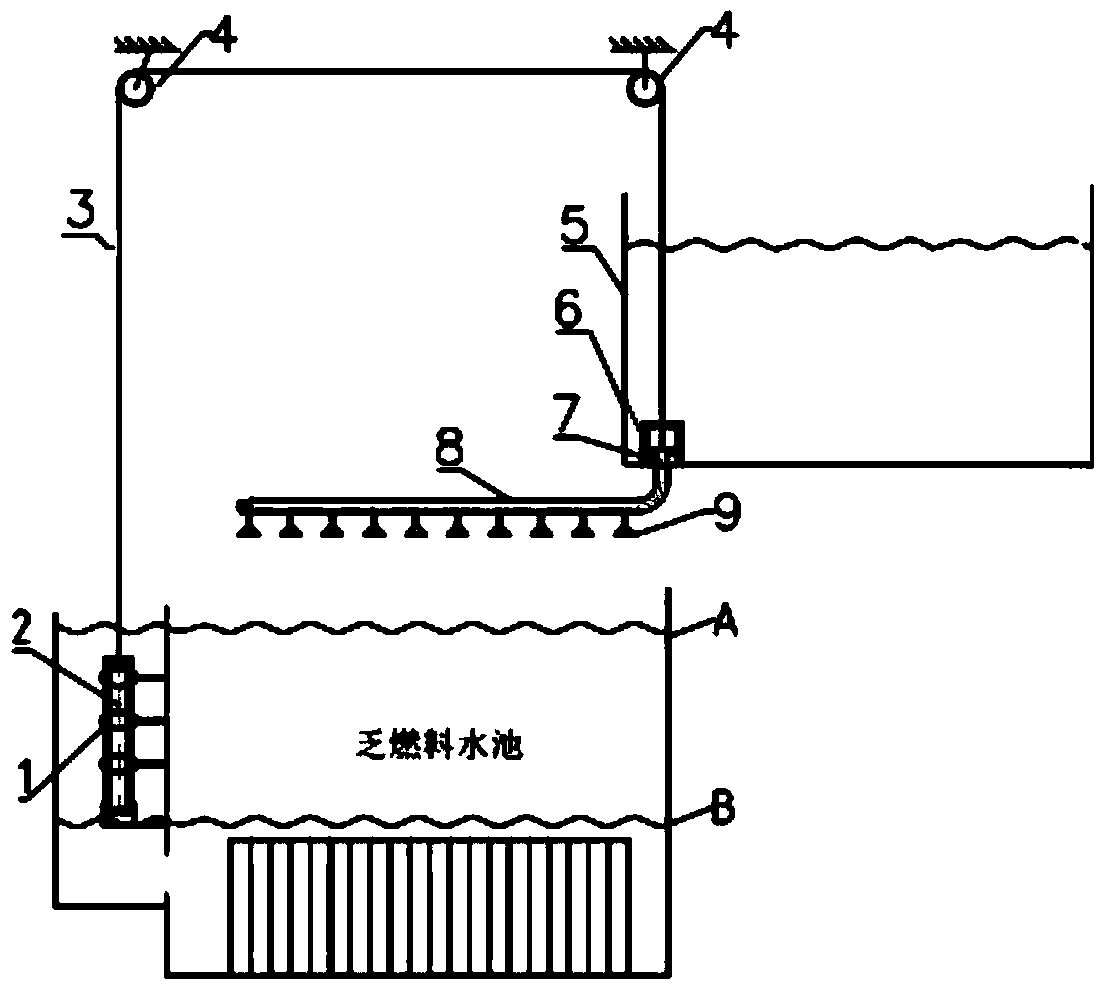

[0022] The present invention provides a passive water replenishment spraying system for a spent fuel pool. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] The structure of the system is as figure 1 As shown, a spray pipe 8 is suspended above the spent fuel pool, and a sprinkler 9 is arranged on it; an outlet is provided at the bottom of the replenishment tank 5, and is connected to the spray pipe 8 through a pipe; A hollow rod 2 is arranged in the frame 1, and a pipe plug 7 is arranged at the outlet of the bottom of the water supply tank 5; A baffle plate 6 with a mesh or hole structure is arranged outside the pipe plug 7 to prevent excessive lifting of the pipe plug 7 while not affecting the discharge of water in the baffle plate 6 .

[0024] Grid frame 1, load-bearing line 3, baffle plate 6, spray pipe 8, and sprinkler 9 are all made of steel or other materials that have no effect on spen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com