E-shaped and I-shaped structure and F-type silicon steel sheets for transformer

A technology for silicon steel sheets and transformers, applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as waste, waste waste, and lack of renewal, save materials and increase economy. Benefit, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

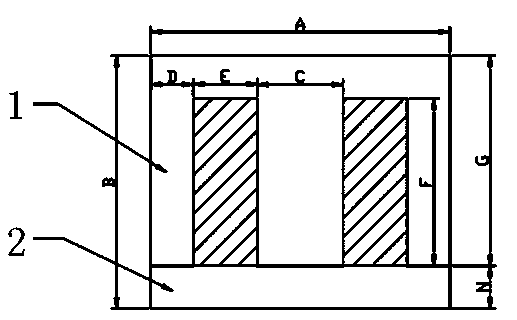

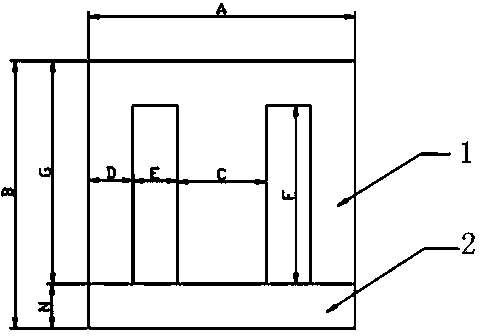

[0036] A silicon steel sheet for EI33F transformers, the length A and height B of the square are both 33mm; the length A of the E-shaped silicon steel sheet is 33mm, the height G is 27.5mm, the width C of the protruding tongue in the middle is 11mm, and the height F is 22mm , the side width D on both sides is 5.5mm, and the width E between the two sides and the protruding tongue in the middle is 5.5mm; the width N of the I-shaped silicon steel sheet is 5.5mm, and the length A is 33mm.

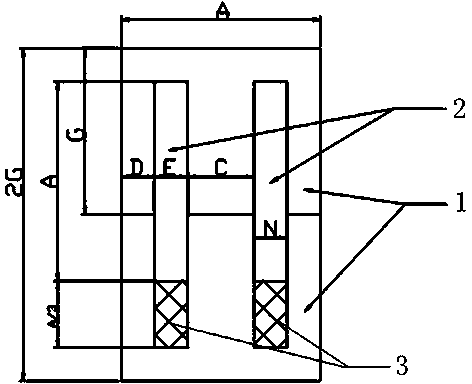

[0037] The F-type silicon steel sheet iron core with EI-shaped structure of the present invention can be punched by sleeve cutting. image 3 , the shaded part shown is the blanking waste area=A / 3 * A / 6 (mm2). The waste accounts for 33% of the total area, and the material utilization rate reaches more than 96%. This alone can save the country 130,000 silicon steel sheets every year More than one ton, with a value of nearly 1 billion yuan, which reduces the cost of products, increases economic be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com