Electric cylinder anti-rotation mechanism

An electric cylinder and anti-rotation technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of fast wear of the drive rod and anti-rotation mechanism of the electric cylinder, reduced service life and reliability of the motor, and high load rate of the motor. Achieve the effect of improving reliability and adaptability, small structure size and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific examples, which are explanations of the present invention rather than limitations.

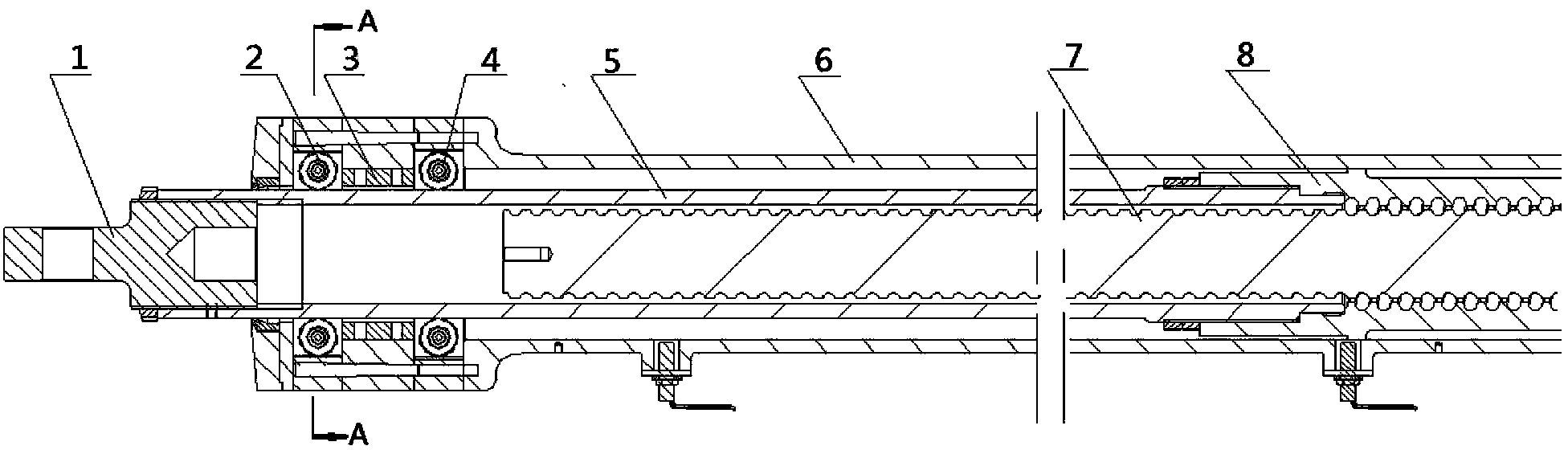

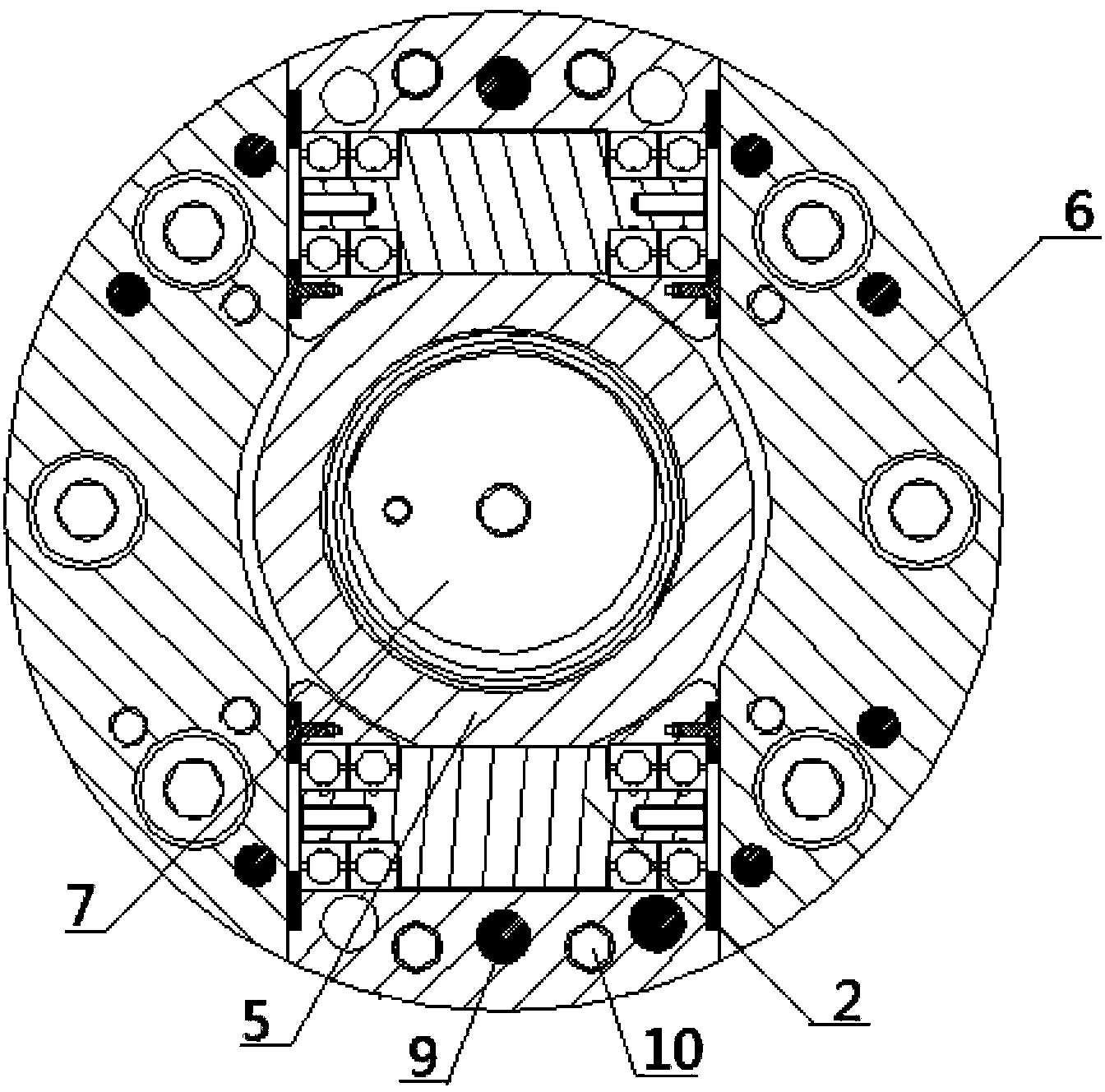

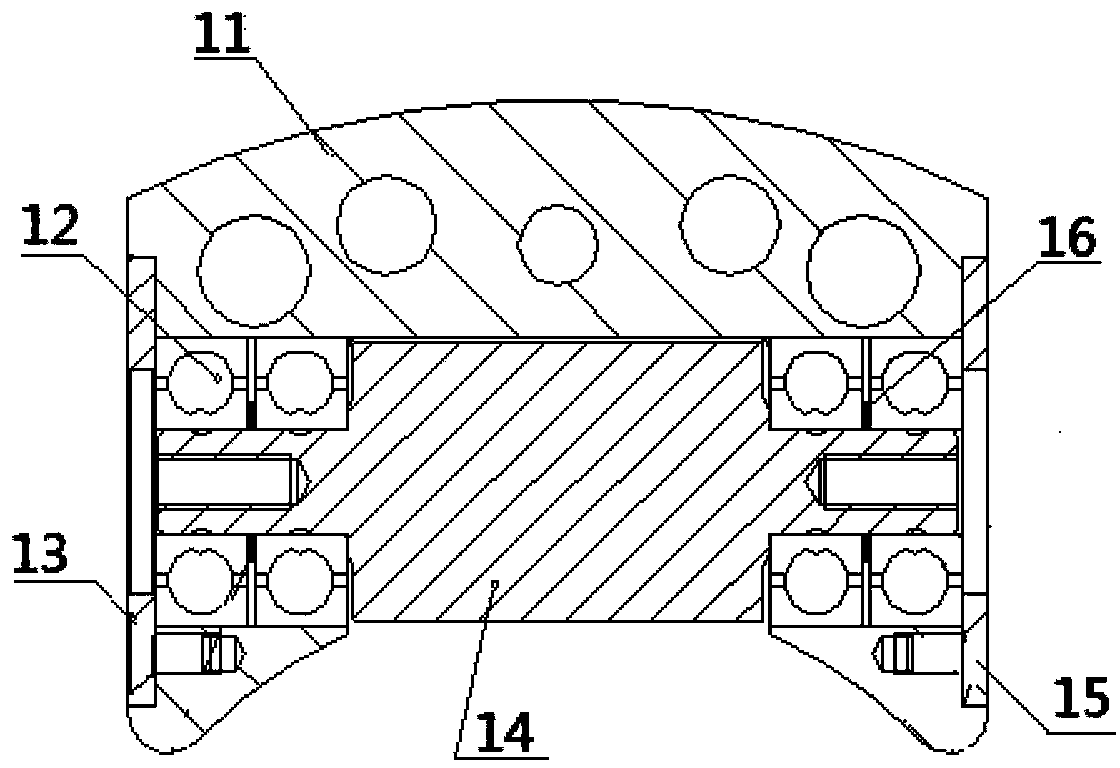

[0025] Such as figure 1 with figure 2 As shown, the present invention is an electric cylinder anti-rotation mechanism, which includes a guide rod 5 threaded with the screw nut 8 of the electric cylinder, and several anti-rotation components; Fixed cage 11, and the roller 14 that is arranged on the cage 11 by rotation; The outer wall of guide rod 5 is provided with anti-rotation plane, and each anti-rotation plane is in rolling contact with at least one roller 14; The centerlines are perpendicular to each other. The setting of anti-rotation planes can be one, two, three or more. In this embodiment, two parallel anti-rotation planes are preferably used as an example. Through the rollers 14 provided in rolling contact on the two anti-rotation planes, one On the one hand, it limits the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com