A Three Degrees of Freedom Magnetic Suspension Switched Reluctance Motor with 12/4 Pole Structure

A switched reluctance motor, degree of freedom technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problem of reducing critical speed and power density, increasing the axial length and control of the suspension motor system Complexity and other issues, to achieve the effect of strong high-speed adaptability, small pulsation, and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

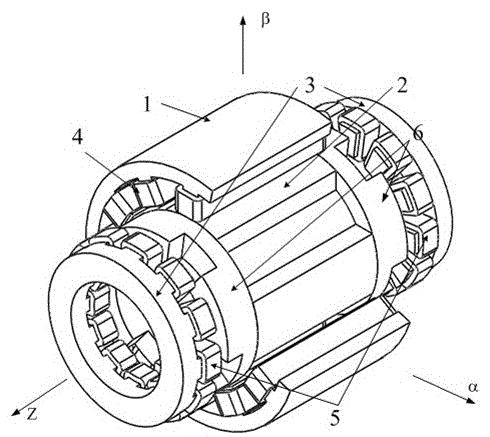

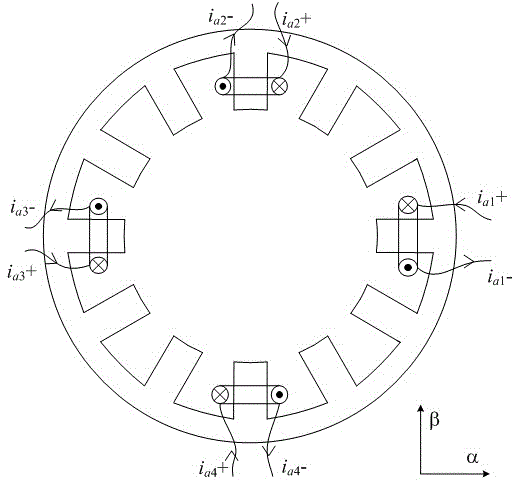

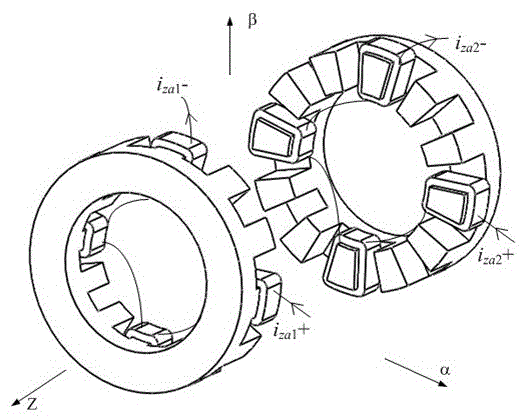

[0026] Such as figure 1 As shown, a three-dimensional structural schematic diagram of a three-degree-of-freedom magnetic levitation switched reluctance motor proposed in the present invention integrates a three-phase 12 / 4 pole radial magnetic field bearingless switched reluctance motor and 2 A three-phase 12 / 4-pole axial magnetic field bearingless switched reluctance motor, of which one three-phase 12 / 4-pole radial magnetic field bearingless switched reluctance motor (hereinafter referred to as a radial motor) includes a radial field motor stator 1, Radial field motor rotor 2 and radial field motor winding 4, two three-phase 12 / 4 pole radial field bearingless switched reluctance motors (hereinafter referred to as axial motors) respectively include axial field stator 3 and axial field motor The rotor 6 and the axial field motor winding 5; the stators of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com