Optoacoustic image pick-up system and optoacoustic image pick-up device

A camera system, photoacoustic technology, applied in measuring devices, ultrasonic/sonic/infrasonic diagnosis, solid analysis using sound/ultrasonic/infrasonic, etc. It can solve problems such as difficulty in building vibrator groups and achieve high-speed shooting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

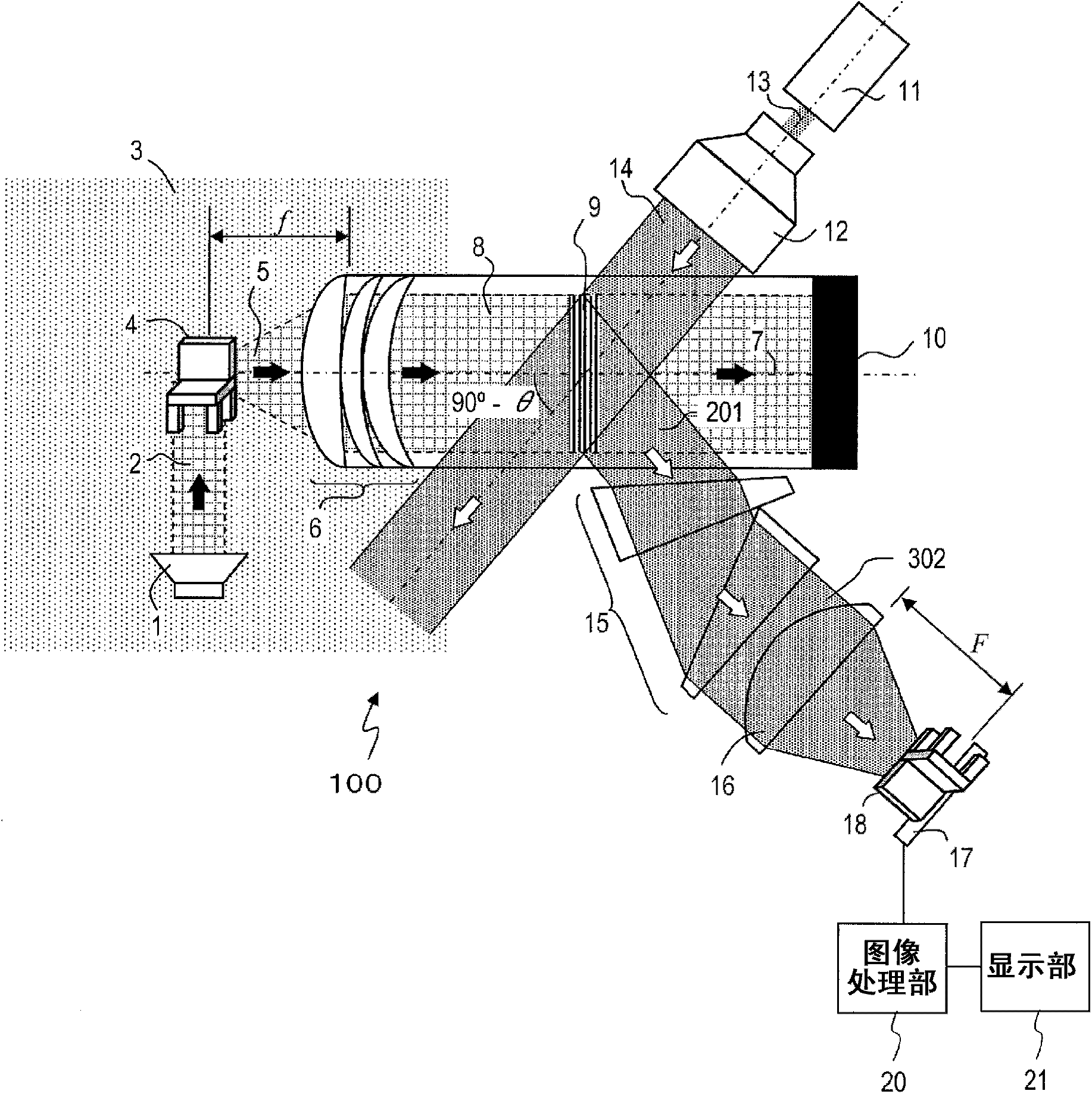

[0060] figure 1 It is a diagram schematically showing the configuration of the photoacoustic imaging system 100 according to the first embodiment of the present invention. The photoacoustic imaging system 100 includes an ultrasonic wave source 1, a photoacoustic medium 8, an acoustic lens 6 disposed on the surface of the photoacoustic medium 8 on the side of the object 4, and an acoustic lens 6 disposed on the surface of the photoacoustic medium 8 facing the surface on which the acoustic lens 6 is disposed. The acoustic wave absorbing end 10 , the monochromatic light source 11 , the beam expander 12 , the distortion correcting part 15 , the imaging lens 16 and the image receiving part 17 are arranged on the surface. and also, figure 1 The illustrated subject 4 and image 18 are not components of the photoacoustic imaging system 100 and are shown for convenience of description.

[0061] The ultrasonic wave source 1 , the acoustic lens 6 , a part of the photoacoustic medium 8...

Embodiment approach 2

[0131] Next, a second embodiment of the present invention will be described.

[0132] Figure 8 It is a figure showing the structure of the acoustic lens 60 of the photoacoustic imaging system 200 of this embodiment. The only difference between the photoacoustic imaging system 200 of this embodiment and the photoacoustic imaging system 100 of Embodiment 1 is the configuration of the acoustic lens. Therefore, descriptions of components other than the acoustic lens 60 of the photoacoustic imaging system 200 are omitted.

[0133] In the photoacoustic imaging system 100 according to Embodiment 1, both the acoustic lens 6 and the photoacoustic medium 8 are made of nanoporous silica. It was demonstrated that the sound velocity of the porous silica body can be varied in a wide range by adjusting the preparation conditions of the nanoporous silica body. Therefore, by using the silica nanoporous body as the acoustic lens 6, flexible selection of the acoustic medium is possible. Lik...

no. 3 approach

[0141] Figure 9 It is a diagram showing a configuration example of the distortion correcting unit 15 of the photoacoustic imaging system according to the present embodiment. The difference between this embodiment and Embodiments 1 and 2 is only the configuration of the distortion correcting unit 15 . Therefore, descriptions of components other than the distortion correcting unit 15 are omitted.

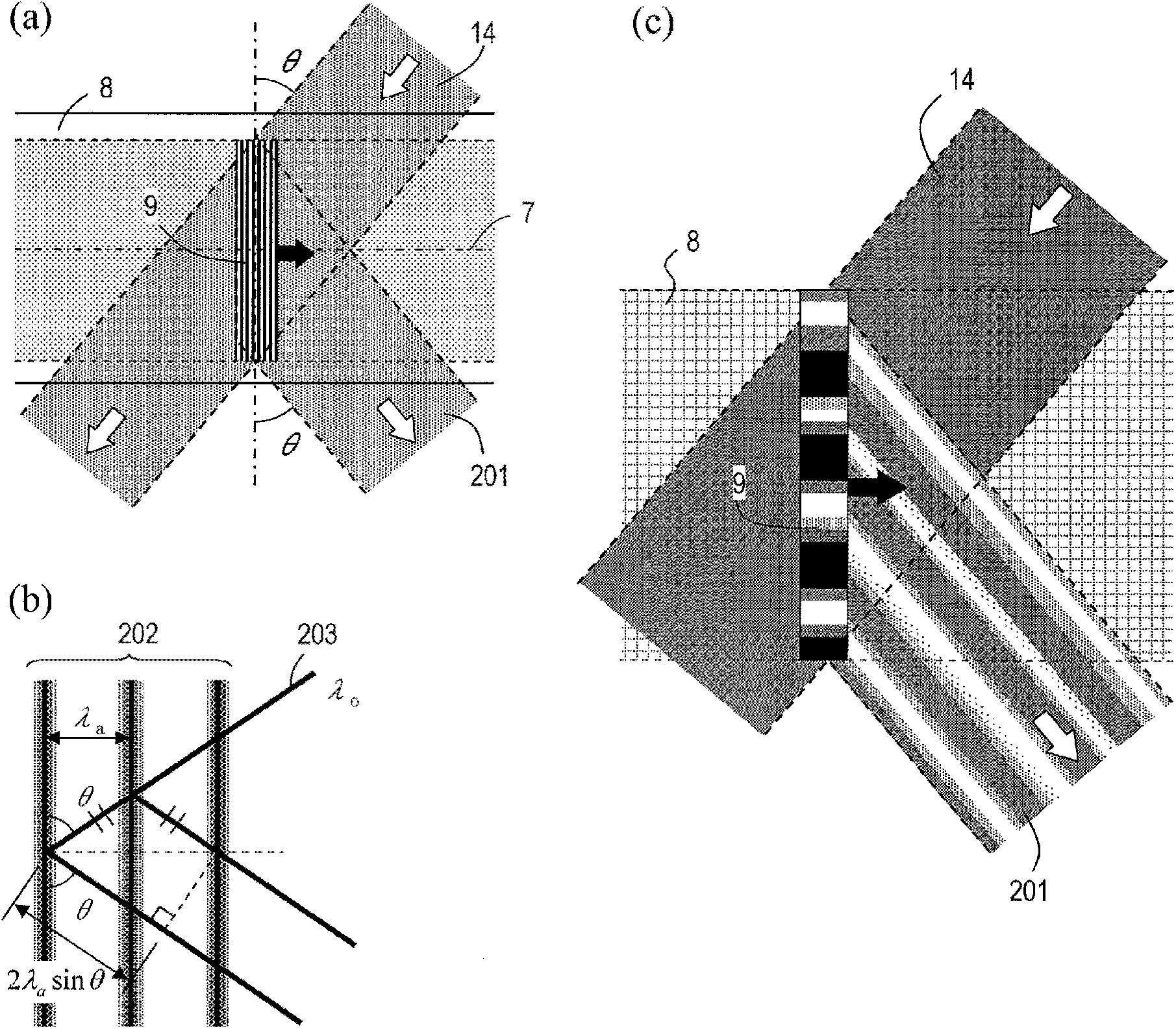

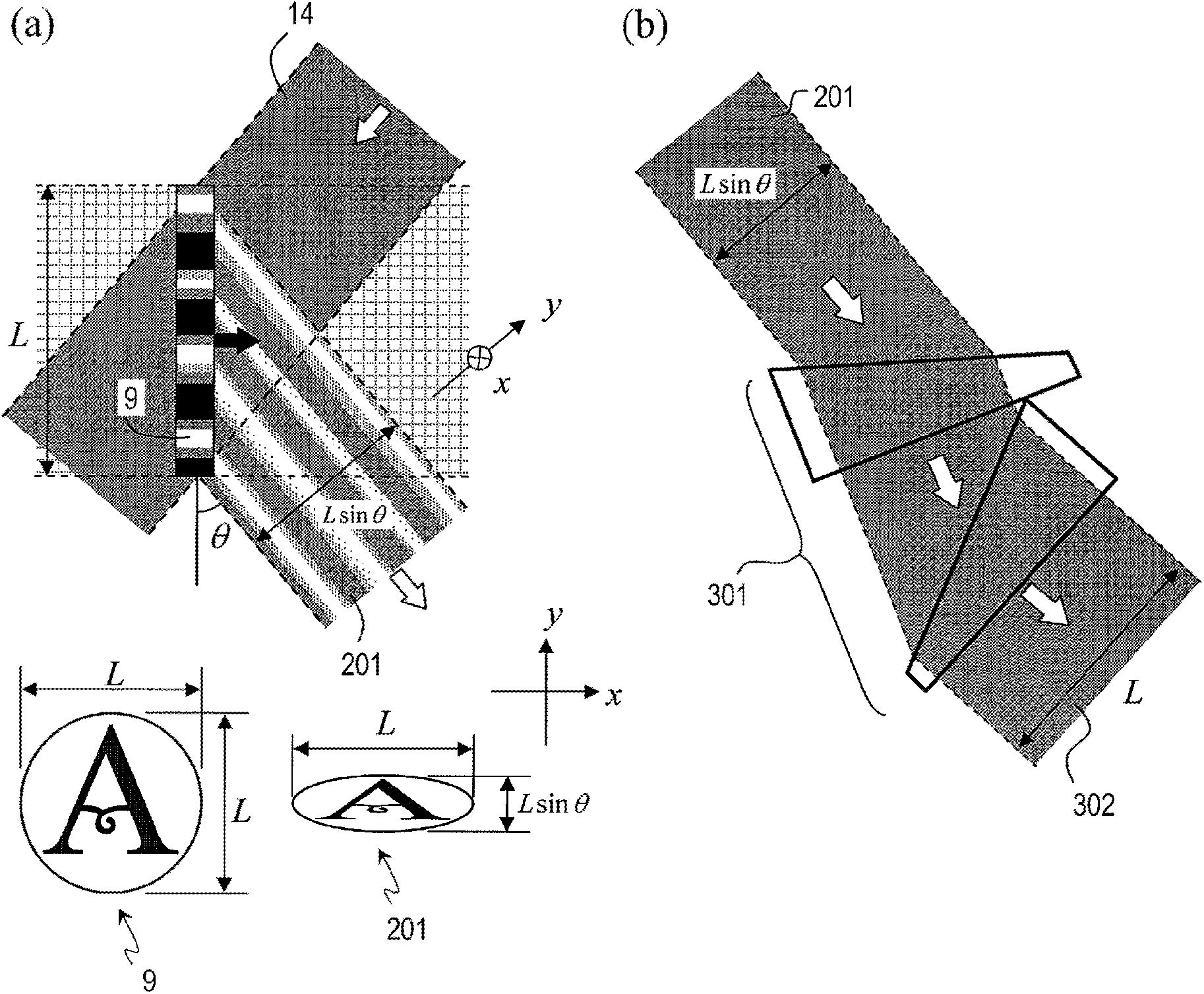

[0142] Such as image 3 As shown, when the diffraction angle is set to θ, the diffracted light 201 generated by Bragg diffraction is compared with image 3 In the direction parallel to the paper surface (y-axis direction), it shrinks to sinθ times. Therefore, if the diffracted light 201 is directly imaged by the imaging lens 6, the image 18 will be distorted and an image similar to the subject 4 cannot be obtained. The function of the distortion correcting part 15 is, in order to solve this problem, make the diffracted light 201 image 3 The direction parallel to the paper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com