Real-time observation device of valve port jet erosion

A real-time observation, valve port technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of hydraulic system operation, valve port erosion wear, zero offset, zero drift and zero leakage, etc., to achieve high-speed Shooting, good sealing, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

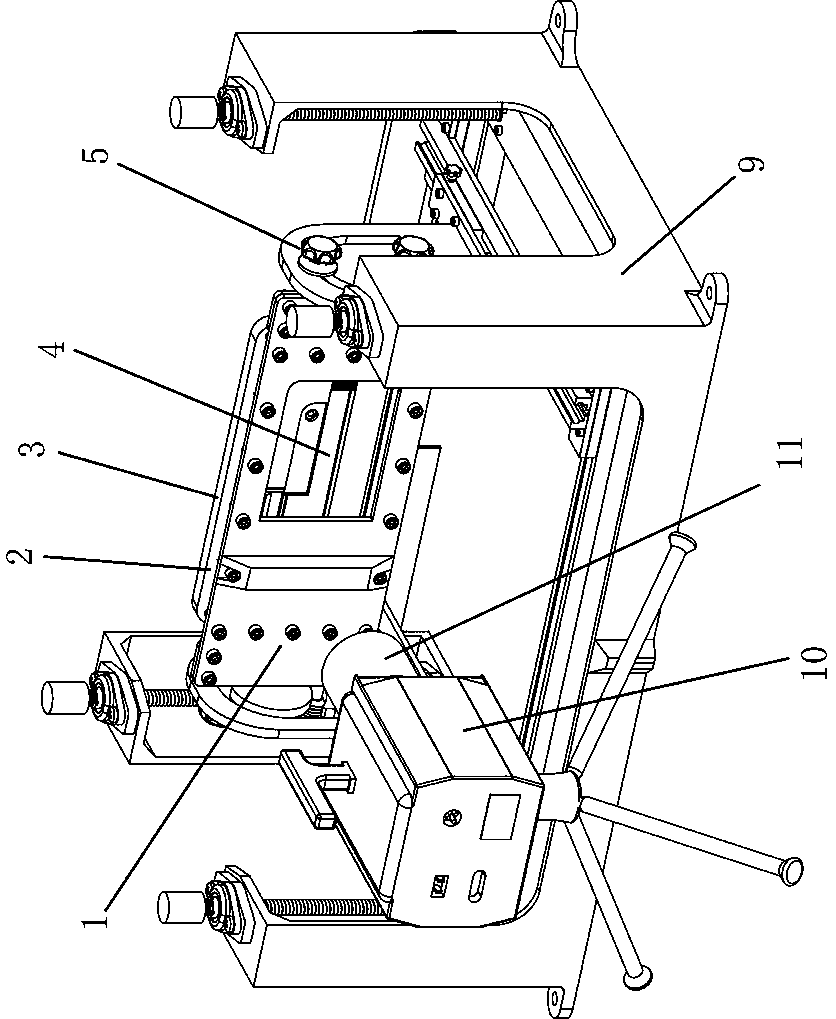

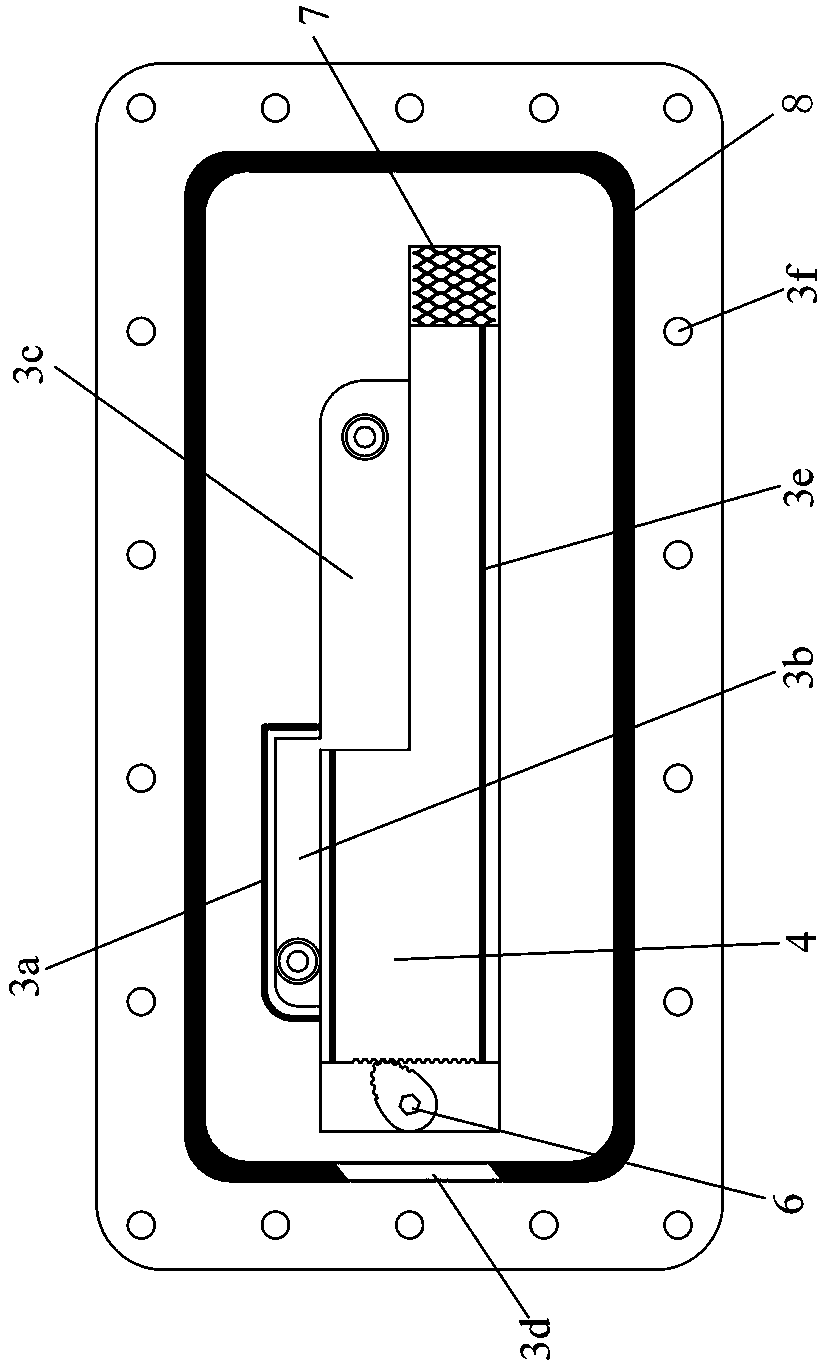

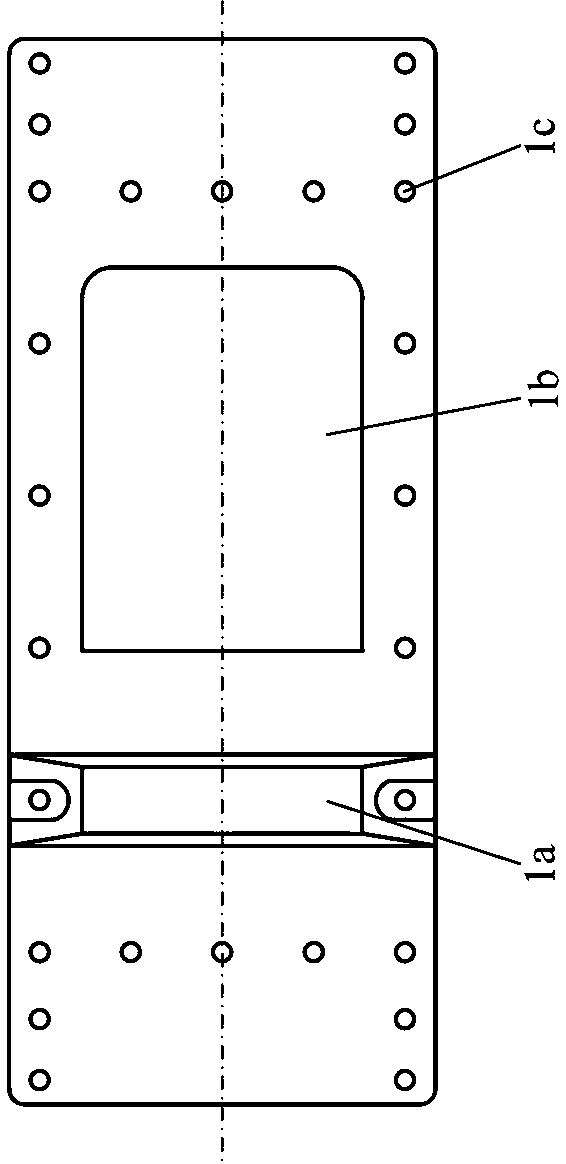

[0009] like figure 1 , figure 2 As shown, the present invention is a real-time observation device for jet erosion at a valve port. Spring 7, large sealing ring 8, positioning bracket 9, high-speed camera 10, and macro lens 11 are composed of a sinking groove processed in the lower cover plate 2, and a simplified valve core 4 is installed in it, and a valve port adjustment cam 6 is installed at one end of the simplified valve core 4 , the other end is equipped with a flat wave spring 7, a large sealing ring 8 is installed along the lower cover plate 3, a positioning bracket 9 is placed on the experimental table, a pair of rotating brackets 5 are installed on it, and the upper cover plate 1 is fixed on the rotating bracket 5. The screws pass through the upper cover plate 1, the transparent plate 2, the lower cover plate 3 and their internal components in order to tighten them and compress the large sealing ring 8, adjust the rotating bracket 5 to make it perpendicular to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com