Dust collection filter, dust collection apparatus provided with same, and manufacturing method for dust collection filter

A filter and dust collection technology, applied in membrane filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of not forming, increasing the number of dusting, not functioning as a telescopic filter layer, etc., and achieves a good yield, Create relaxing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

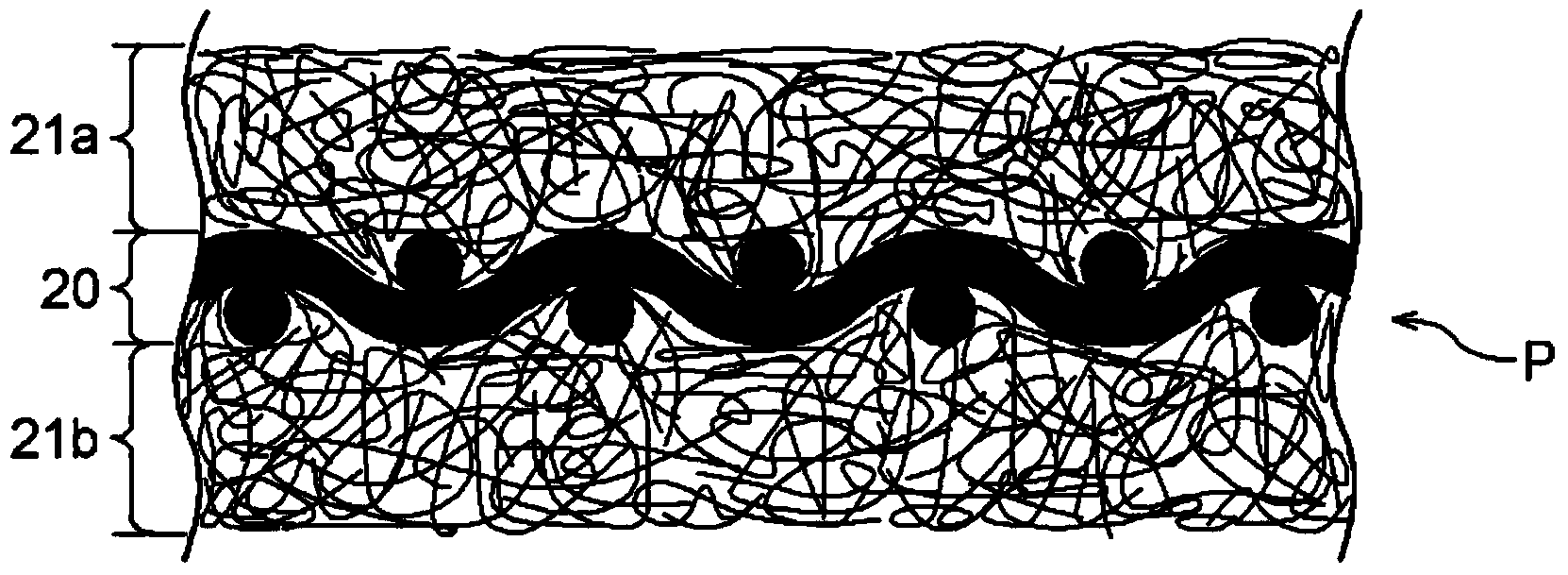

[0096] Examples 1 and 2 are cases in which the warp yarns 20a and weft yarns 20b in the base fabric layer 20 are arranged obliquely with respect to the cylinder axis direction X of the filter cloth P, that is, the dust collection filter composed of the offset base fabric layer 20 is used. In the case of the device F, embodiment 1 is a situation in which tension is not provided by the hammer body 54, and embodiment 2 is a situation in which tension is provided by the hammer body 54.

[0097] In addition, Comparative Examples 1 and 2 use conventional dust-collecting filters in which the warp yarns 20a and weft yarns 20b in the base fabric layer 20 are in the cylindrical circumferential direction Y and cylindrical axial direction X of the filter cloth P (that is, in a regular lattice shape). In the case of comparative example 1, the tension is not provided by the hammer, and the comparative example 2 is the tension is provided by the hammer.

[0098] In each of the above-describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com