Grinding machine device with pivotable mounting of a grinding spindle unit and method for pivoting a grinding spindle unit on a grinding machine

A grinding machine, pivoting shaft technology, applied in the field of grinding machine devices, can solve the problems of different, affecting grinding results, fluctuations in rotation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

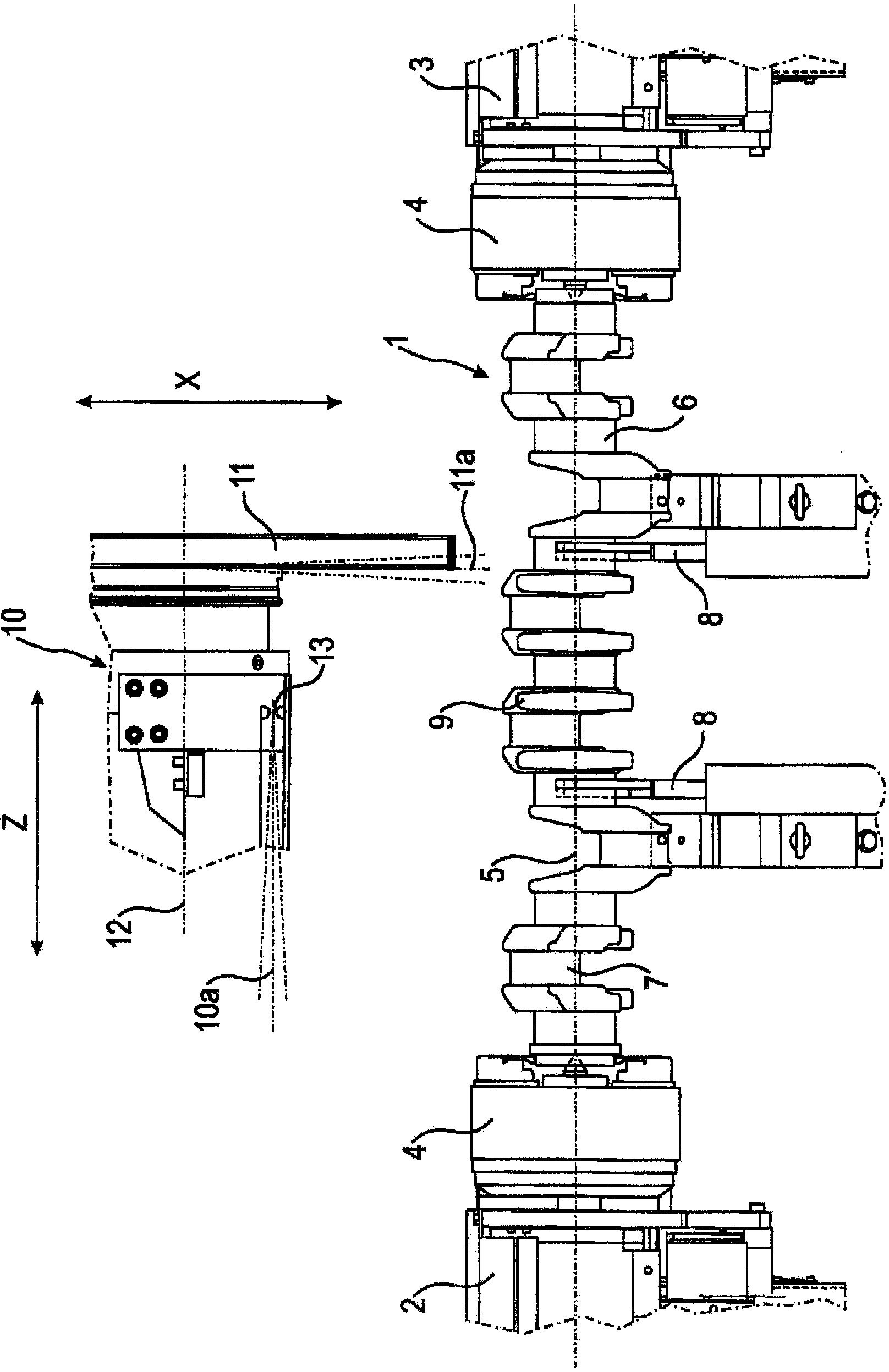

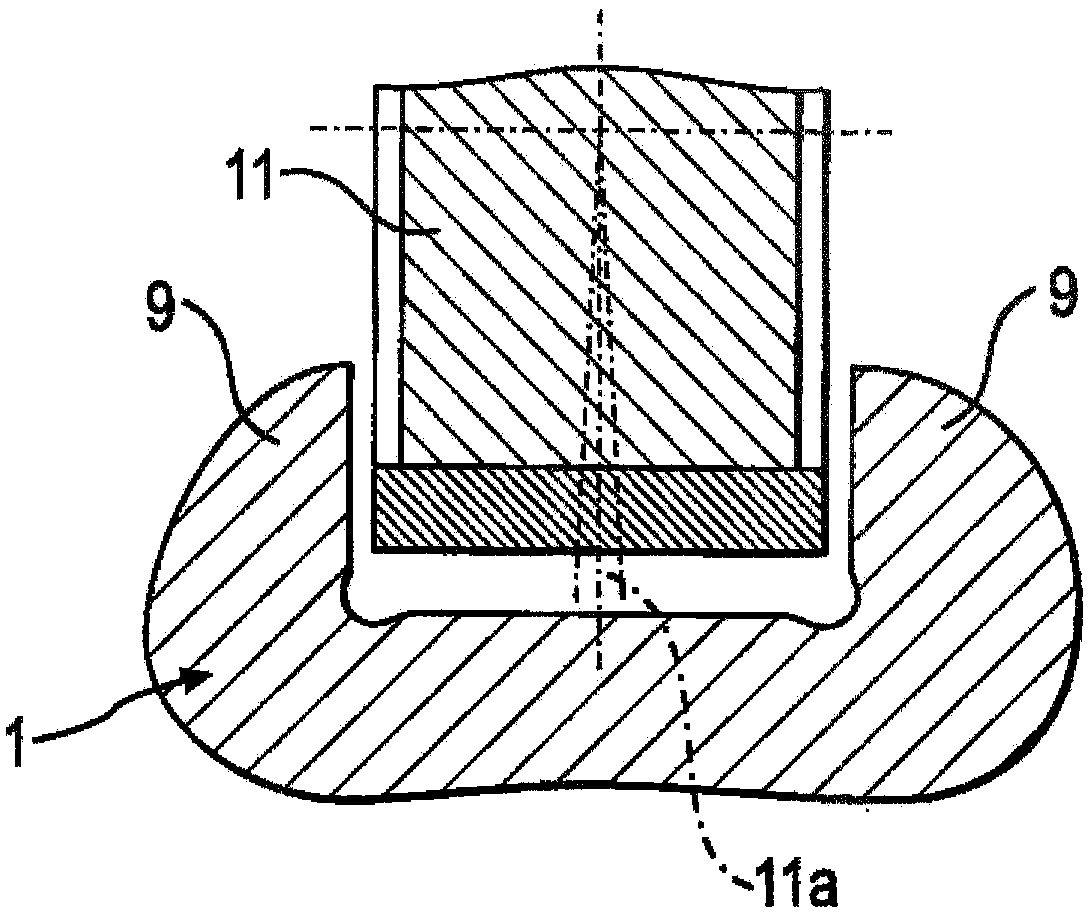

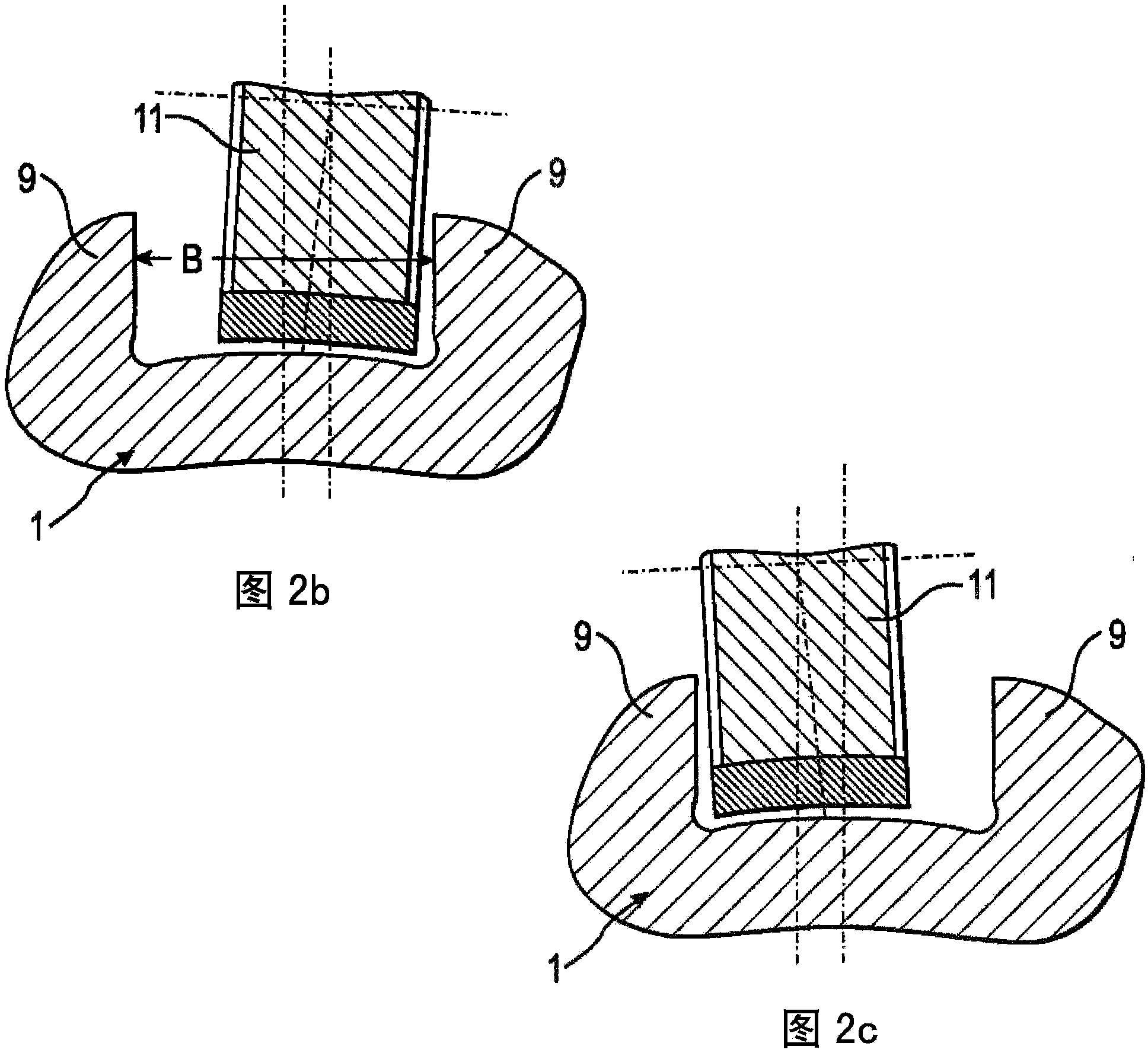

[0039] exist figure 1 In , the crankshaft 1 of a 6-cylinder internal combustion engine is shown as a workpiece, which is clamped for grinding between a workpiece headstock 2 and a tailstock 3 . Both the workpiece headstock 2 and the tailstock 3 have a chuck 4 with complementary chuck jaws and tips; the crankshaft 1 is thus driven in rotation about its longitudinal axis 5 extending through the main bearing 6 . The crankshaft 1 has seven main bearings 6 and six pin bearings 7 ; the two main bearings 6 are supported here via fastening brackets 8 . The main and pin bearings 6 , 7 are interconnected by crank arms 9 . The grinding spindle unit 10 extends along the crankshaft 1, only at figure 1 The end region of the grinding spindle unit 10 positioned on one side of the grinding wheel 11 is shown in . Reference numeral 12 designates the axis of rotation of the grinding wheel 11 , which is produced by the drive shaft to which the grinding wheel 11 is fixed.

[0040] The normal po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com