Method for producing tofu

A manufacturing method and a technology for tofu, which are applied in the directions of dairy products, food heat treatment, food ingredients as coagulants, etc., can solve problems such as insufficient effect, and achieve the effects of excellent elasticity, reduced unpleasant taste, and good flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Soymilk produced by a conventional method at a tofu factory production site was used for the test. This soymilk is soymilk obtained by using Canadian soybeans, soaking them overnight, grinding them with a grinder while adding water, heating them in an indirect cooking pot, and separating bean curd residues with a screw press device. . The soymilk was divided into centrifuge tubes for a high-speed centrifuge (Hitachi Koki Co., Ltd. 18PR-52) in the laboratory, and centrifuged at 8000 rpm (the centrifugal acceleration at the center of the tube was about 6000×g) for 15 minutes. .

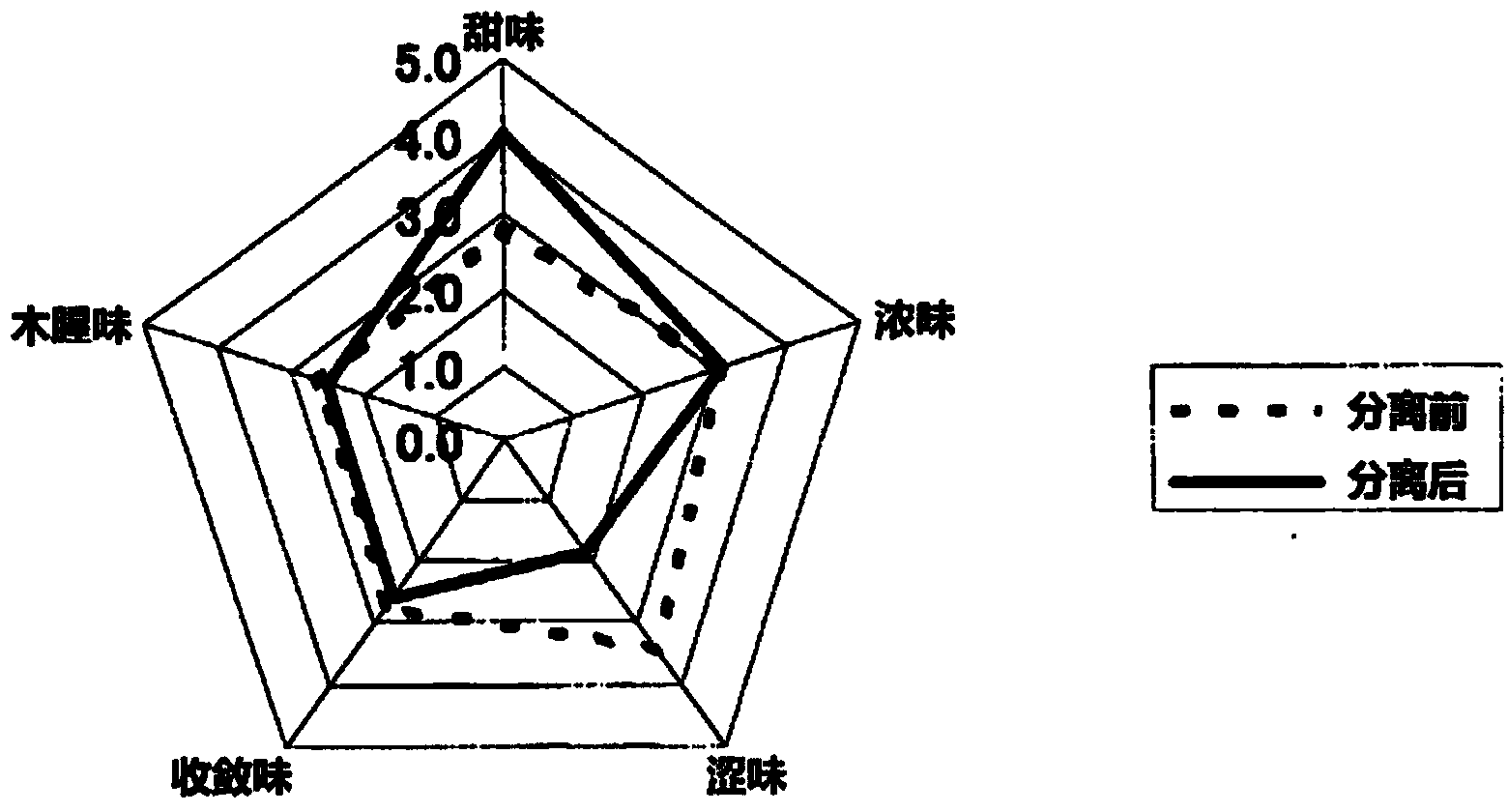

[0113] The temperature of the soybean milk immediately before centrifugation is 40°C. Remove the floating matter in the upper layer of the tube after centrifugation, and separate the soybean milk liquid in the lower layer to obtain soybean milk. The control soymilk used for centrifugation was the soymilk before separation, and the soymilk after centrifugation was the soymilk after separation, ...

Embodiment 2

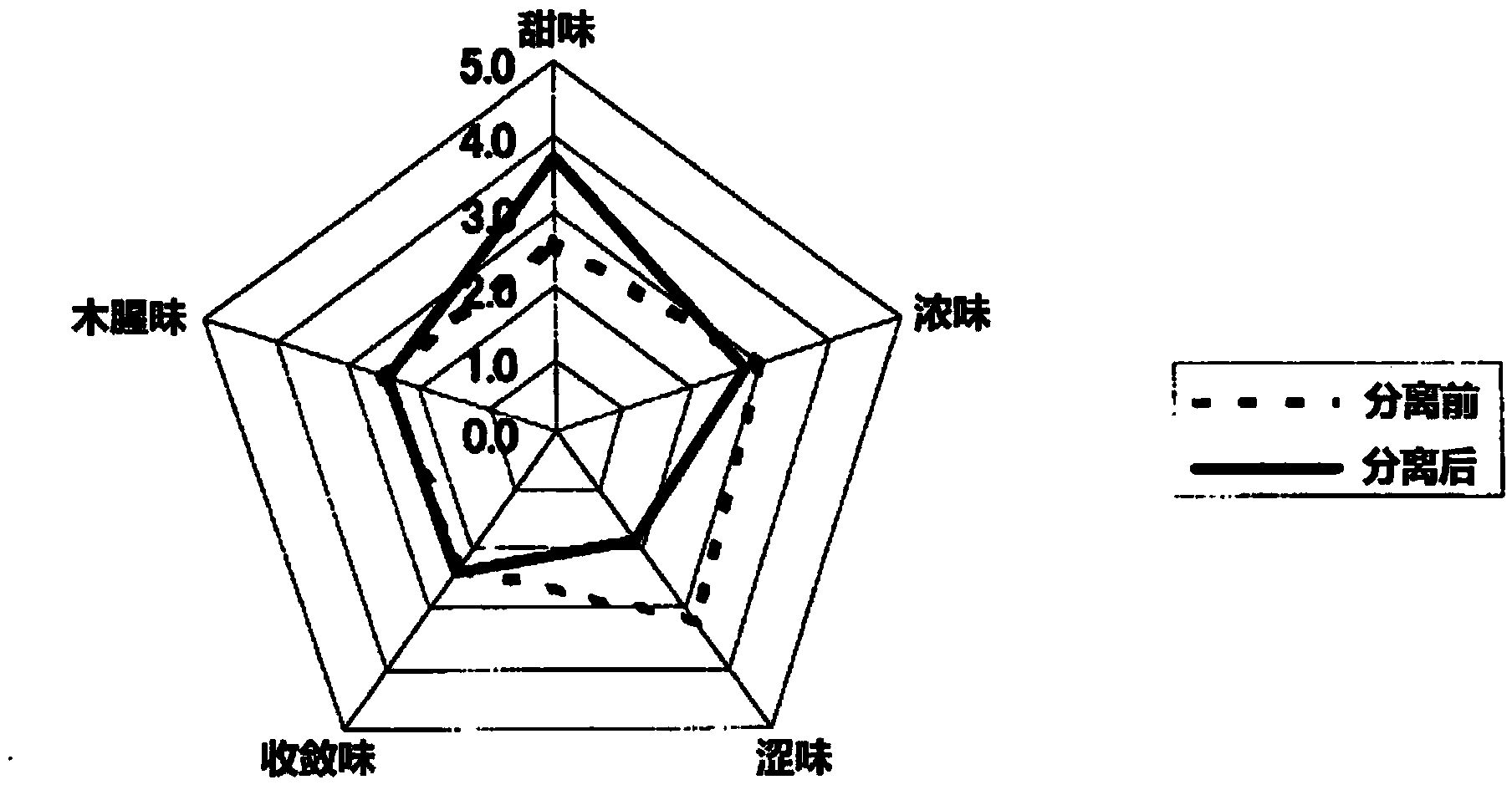

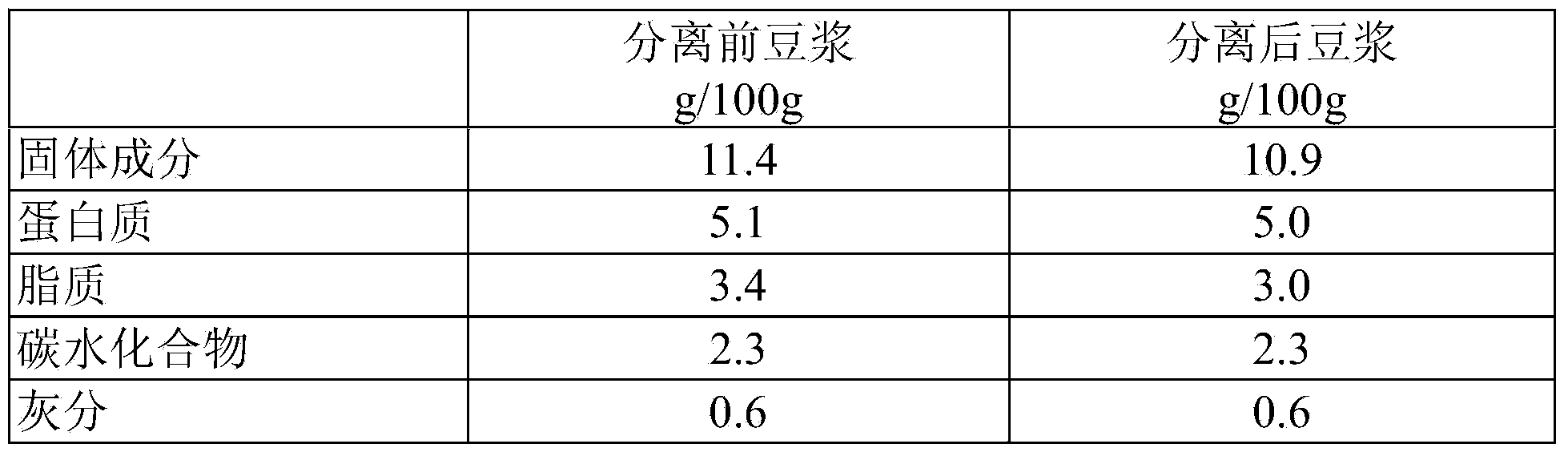

[0135] Using the same soybean milk as that used in Example 1, centrifugation was performed under the following conditions. That is, after soybeans are ground and boiled, the bean curd residue is separated by a screw press device, and the soybean milk immediately after separation is extracted from the manufacturing site, and passed through a high-speed centrifuge. The temperature of soybean milk before centrifugation is 65°C. Centrifugal separation was carried out at a centrifugal acceleration of 6000×g for 20 minutes to remove the floating components in the upper layer and separate the soybean milk liquid in the lower layer to obtain soybean milk. Table 5 shows the component analysis values of soybean milk before separation and soybean milk after separation.

[0136] table 5

[0137]

[0138] After separation, the lipid of soy milk is half of that of soy milk before separation. Therefore, using the soybean milk to make tofu can become tofu with reduced calories.

[01...

Embodiment 3

[0167] At the production site of the tofu factory, raw soybean milk, boiled soybean milk, and soybean milk separated from bean curd residue were extracted from a production line based on a conventional method for continuous production, and used for testing.

[0168] This production line uses Canadian soybeans, soaks them in water overnight, grinds them with a grinder while adding water, heats them in a continuous heating tank, and separates okara with a screw press device to produce soybean milk.

[0169] In the process of continuous flow, "raw soybean juice" just after grinding in a grinder, "cooked soybean juice" immediately after heating in a continuous heating tank, and "soymilk" immediately after separating bean curd residue with a screw press device are extracted separately. .

[0170] Each raw material solution was divided into centrifuge tubes of a high-speed centrifuge (Hitachi Koki Co., Ltd., 18PR-52) in the laboratory, and centrifuged at 8000rpm (the centrifugal acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com