Polyacrylic acid/13X molecular sieve adsorbent and method for preparing same

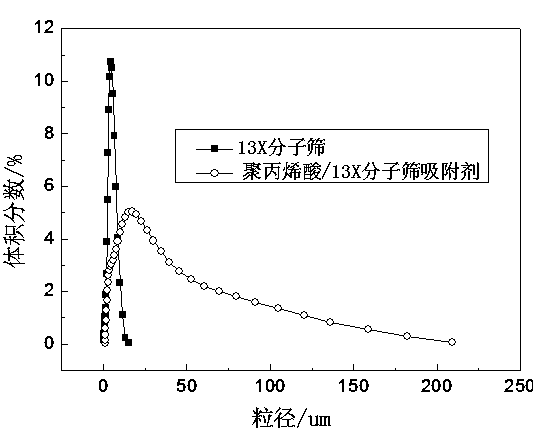

A technology of polyacrylic acid and molecular sieve, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, etc. It can solve the problem of large usage of modifier OTMAC, increase of organic pollutant adsorption performance, and insufficient pore size of molecular sieve, etc. problems, to achieve the effect of uniform adsorbent composition, easy sedimentation, and large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

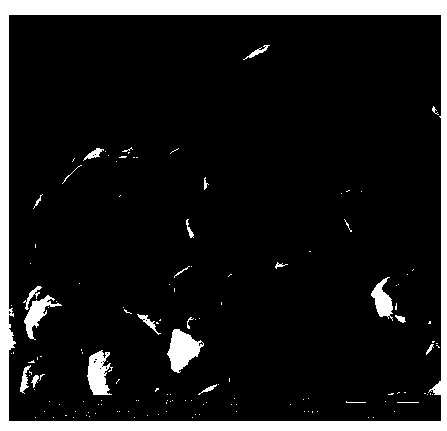

Image

Examples

Embodiment 1

[0024] A polyacrylic acid / 13X molecular sieve adsorbent and a preparation method thereof. The concrete steps of its preparation method are:

[0025] Step 1: First prepare a polyacrylic acid solution with a mass fraction of 13.5 wt%, and then use sodium hydroxide solution to adjust the pH value of the polyacrylic acid solution to 3.8-4.0.

[0026] Step 2: Add 13X molecular sieve to the polyacrylic acid solution after adjusting the pH value under stirring conditions, the amount of 13X molecular sieve added per liter of the polyacrylic acid solution after adjusting the pH value is 55 ~ 58g, to obtain a mixed solution of polyacrylic acid and 13X molecular sieve and then stirring the mixture of polyacrylic acid and 13X molecular sieve at room temperature at a speed of 200-250r / min for 2.5-3h to obtain a polyacrylic acid / 13X molecular sieve solution.

[0027] Step 3: Put the prepared polyacrylic acid / 13X molecular sieve solution directly in a muffle furnace, calcinate at 100-150° C...

Embodiment 2

[0030] A polyacrylic acid / 13X molecular sieve adsorbent and a preparation method thereof. The concrete steps of its preparation method are:

[0031] Step 1: First prepare a polyacrylic acid solution with a mass fraction of 13.5 wt%, and then use sodium hydroxide solution to adjust the pH value of the polyacrylic acid solution to 3.8-4.0.

[0032] Step 2: Add 13X molecular sieve to the polyacrylic acid solution after adjusting the pH value under stirring conditions, the amount of 13X molecular sieve added per liter of the polyacrylic acid solution after adjusting the pH value is 55 ~ 58g, to obtain a mixed solution of polyacrylic acid and 13X molecular sieve and then stirring the mixture of polyacrylic acid and 13X molecular sieve at room temperature at a speed of 200-250r / min for 2.5-3h to obtain a polyacrylic acid / 13X molecular sieve solution.

[0033] Step 3: The prepared polyacrylic acid / 13X molecular sieve solution is directly placed in a muffle furnace, calcined at 150-2...

Embodiment 3

[0036] A polyacrylic acid / 13X molecular sieve adsorbent and a preparation method thereof. The concrete steps of its preparation method are:

[0037] Step 1: First prepare a polyacrylic acid solution with a mass fraction of 13.5 wt%, and then use sodium hydroxide solution to adjust the pH value of the polyacrylic acid solution to 4.0-4.2.

[0038]Step 2: Add 13X molecular sieve to the polyacrylic acid solution after adjusting the pH value under stirring conditions, the amount of 13X molecular sieve added per liter of the polyacrylic acid solution after adjusting the pH value is 57~60g, to obtain a mixed solution of polyacrylic acid and 13X molecular sieve and then stirring the mixture of polyacrylic acid and 13X molecular sieve at room temperature at a speed of 250-300r / min for 2-2.5h to obtain a polyacrylic acid / 13X molecular sieve solution.

[0039] Step 3: Put the prepared polyacrylic acid / 13X molecular sieve solution directly in a muffle furnace, calcinate at 100-150° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com