Magnetic separation device and magnetic separation method for reducing hematite-containing materials by microwave

A magnetic separation device and iron mineral technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of unqualified equipment structure and related technologies, poor reduction roasting quality, and large dust content in tail gas. Achieve the effect of shortening the response time, reasonable distribution of the magnetic system, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

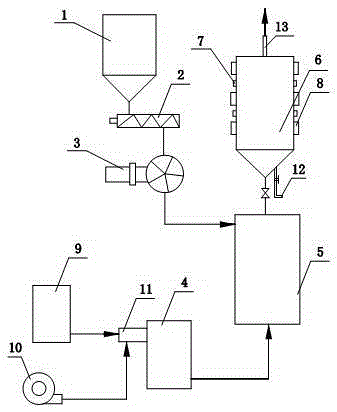

[0032] Example 1: see Figure 1-Figure 3 , A magnetic separation device for microwave reduction of hematite-containing mineral materials, including a silo 1, a screw feeder 2, a star feeder 3, a preheating reactor 5 and a microwave magnetic separator 6; the upper part of the microwave magnetic separator 6 , The bottom is respectively provided with a discharge port 13 and a discharge port 12; the bottom of the preheating reaction furnace 5 communicates with the combustion chamber 4, the gas in the gas storage tank 9 and the air blown in by the blower 10 are mixed and burned through the burner 11 The chamber 4 is combusted, and the high-temperature CO gas produced after the combustion enters from the bottom of the preheating reactor 5.

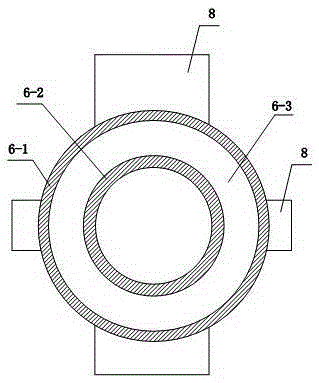

[0033] The microwave magnetic separator 6 includes: a reactor shell 6-1, a reactor cavity 6-2, an air inlet pipe 6-4, an air outlet pipe 6-5, a discharge pipe 6-6, a microwave source 7, a magnetic system 8. The air inlet pipe 6-4 communicates with...

Embodiment 2

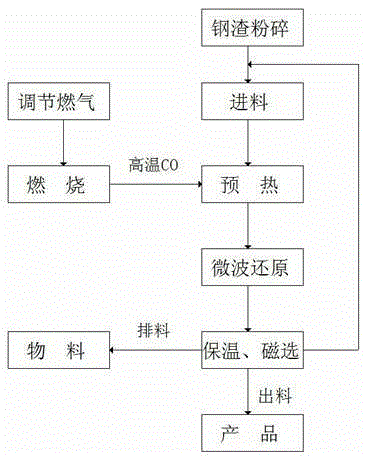

[0035] Example 2: see Figure 4 , Using the magnetic separation device of Example 1 to magnetically separate hematite (Fe 2 O 3 ) The material method includes the following steps:

[0036] The hematite-containing mineral material is crushed to 80-100 mesh powder, and added to the silo 1, the powder enters the preheating reactor 5 through the screw feeder 2, the star feeder 3, and the preheated powder Enter the microwave magnetic separator 6 through the air inlet pipe 6-4 for microwave heat treatment and magnetic separation; the products after magnetic separation are discharged from the discharge port 12 through the discharge pipe 6-6, and other materials are discharged through the outlet pipe 6-5. Discharge from the discharge port 13; or discharge through the discharge port after dust removal.

[0037] Among them, the material containing hematite can be steel slag, low-grade limonite, iron ore and other ores.

[0038] The preheating is to heat the powder to 300-400°C; the microwave ...

Embodiment 3

[0040] Example three: see Figure 4 , The method of magnetic separation of steel slag using a magnetic separation device, the adopted magnetic separation device is as described in Example 1. The method includes the following steps:

[0041] The steel slag is crushed into 80-100 mesh powder, and 100kg of powder is measured and added to the silo 1. The powder in the silo 1 passes through the screw feeder 2 and the star feeder 3, and enters the preheating reactor 5 for preheating ;

[0042] Adjust the gas in the gas storage tank 9 and the air blown by the blower 10, mix them through the burner 11 and burn them in the combustion chamber 4. The high temperature CO gas produced after combustion enters the bottom of the preheating reactor 5 to preheat the materials;

[0043] After the preheated material reaches 300℃, it enters the microwave magnetic separator 6 through the air inlet pipe 6-4 for microwave heat treatment. The microwave power is 15KW. Adjust the microwave output power to turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com