Tea sorting device

A sorting device, tea technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of reducing product production efficiency, large random factors, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

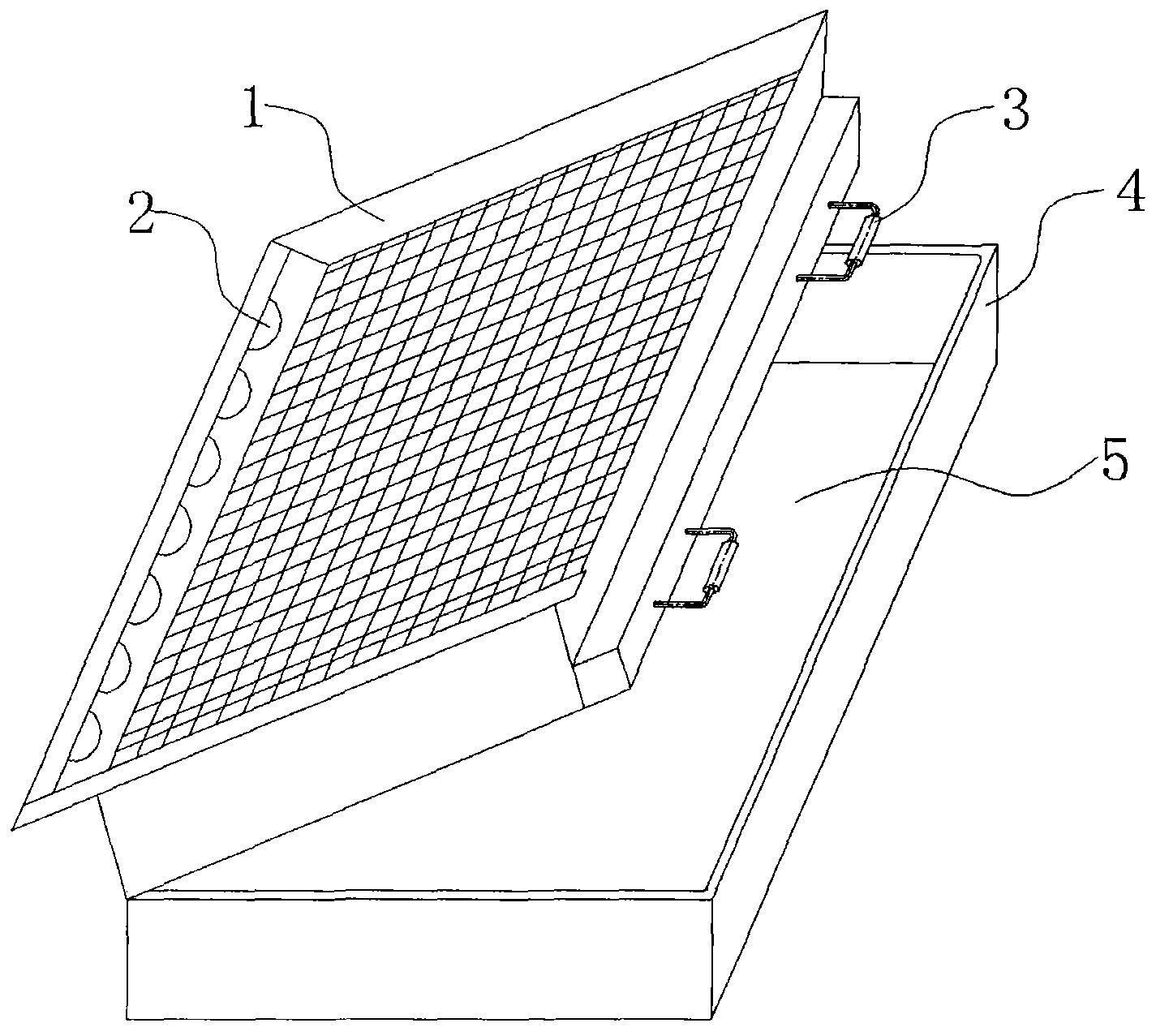

[0013] see figure 1 , a sorting device for tea leaves, comprising a first selection layer 1), a discharge port (2), a screen (3), a handle (4), and a second selection layer (5). Before starting the vibrating device, the first The selection layer (1) and the second selection layer (5) are closed by the handle (4), and the vibration device drives the first selection layer (1) and the second selection layer (5), and the fine tea leaves are drawn from the first selection layer (1) The inner sieve (falling into the second selection layer (5), because the sieve holes on the sieve are uniform, the size of the screened tea leaves is relatively consistent, and the classification is more obvious. After the screening, just turn the handle (4) to tilt the first The tea leaves of the selection layer (1) can be poured out from the discharge port (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com