Fixed semiautomatic flame cutting machine

A flame cutting machine, cutting machine technology, applied in gas flame welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high welding training cost, waste of materials and manpower, etc., to solve inconvenient handling, save processing costs, beveled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

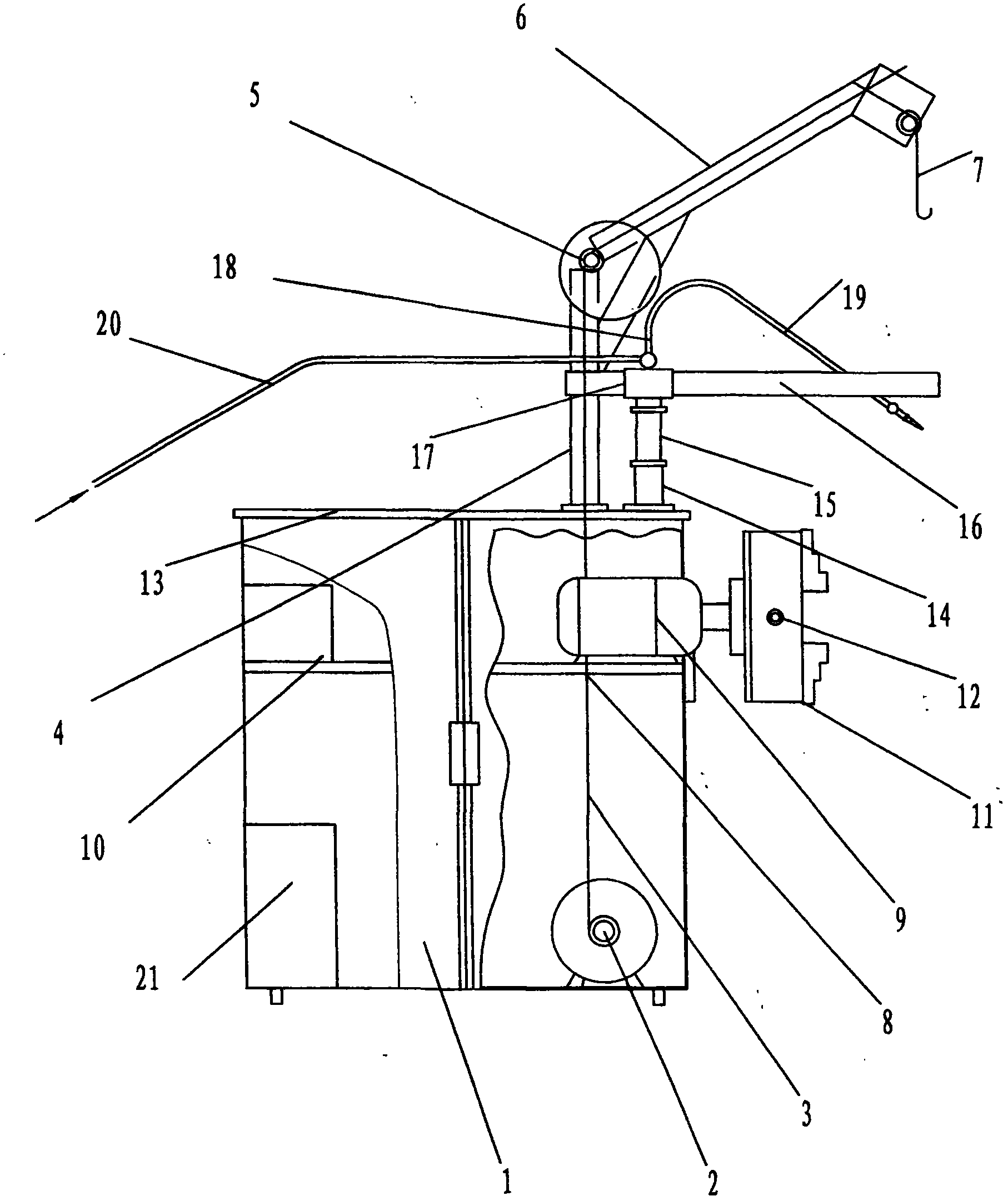

[0009] A fixed semi-automatic flame cutting machine, comprising a cutting machine cabinet 1, a rotating motor fixing plate 8 is arranged in the cutting machine cabinet 1, a cutting gun fixing platform 13 is arranged on the top of the cutting machine cabinet 1, and a cutting gun fixing platform 13 is arranged on the top of the cutting machine cabinet 1. Lifting motor 2 and electrical control box 21 are respectively arranged on the bottom plate, and rotating motor 9 and rotating motor speed regulator 10 are respectively arranged on rotating motor fixed plate 8, and electric control box 21 is connected with lifting motor 2 and rotating motor speed respectively. The controller 10 is electrically connected, the rotary motor speed controller 10 is electrically connected with the rotary motor 9, a three-jaw chuck 11 is connected on the output shaft of the rotary motor 9, and a vertical suspension rod 4 is fixedly arranged on the cutting torch fixing platform 13. The top of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com