Clamp for machining plastic impeller of water pump for automobile engine

A technology for automobile engines and water pumps, which is used in metal processing mechanical parts, manufacturing tools, metal processing equipment, etc., can solve the problems of increased parts clamping and processing difficulty, impeller vibration, and runout, and achieves guaranteed contour and coaxiality. degree, improve the rotation accuracy, reduce the effect of beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

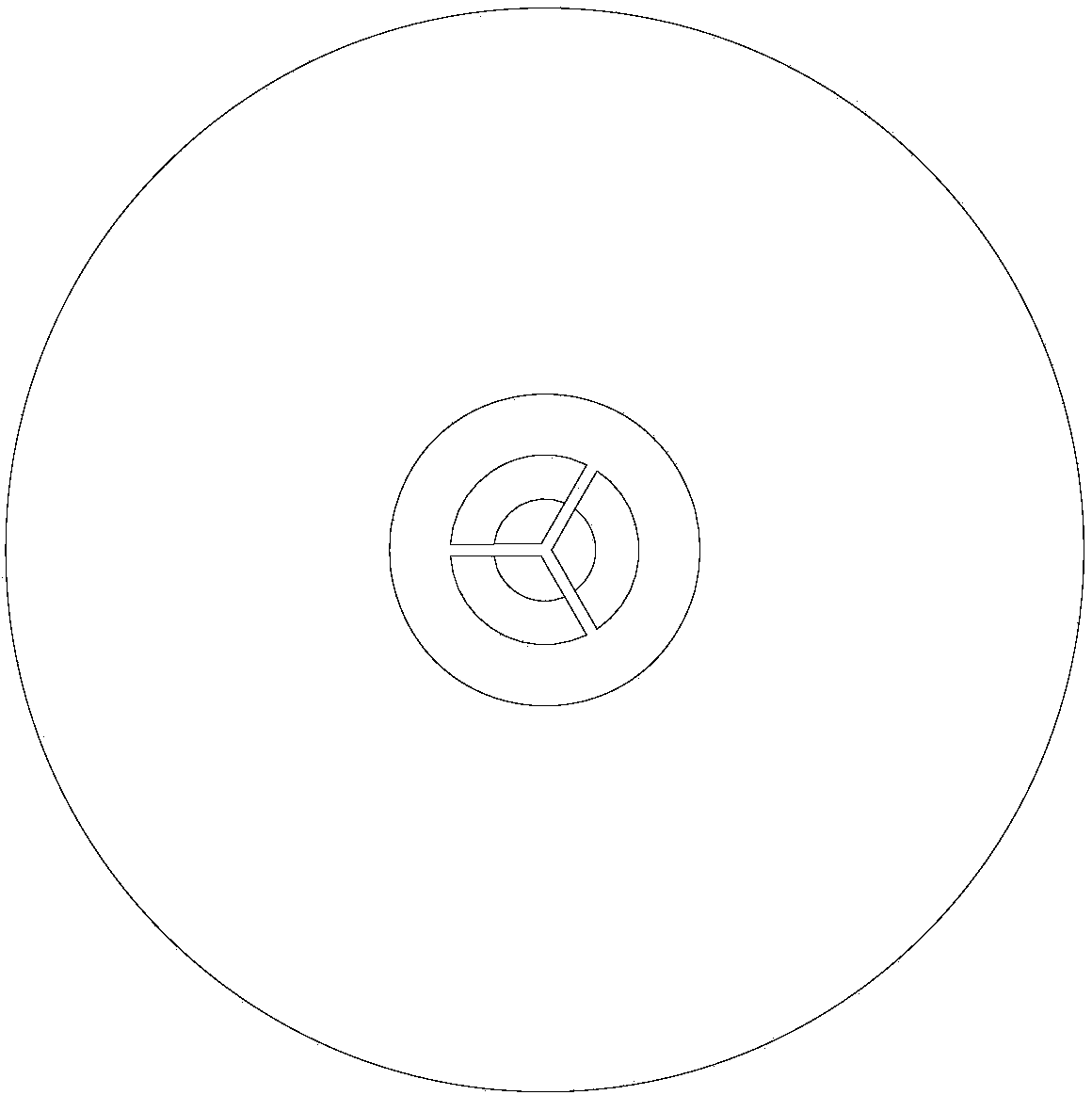

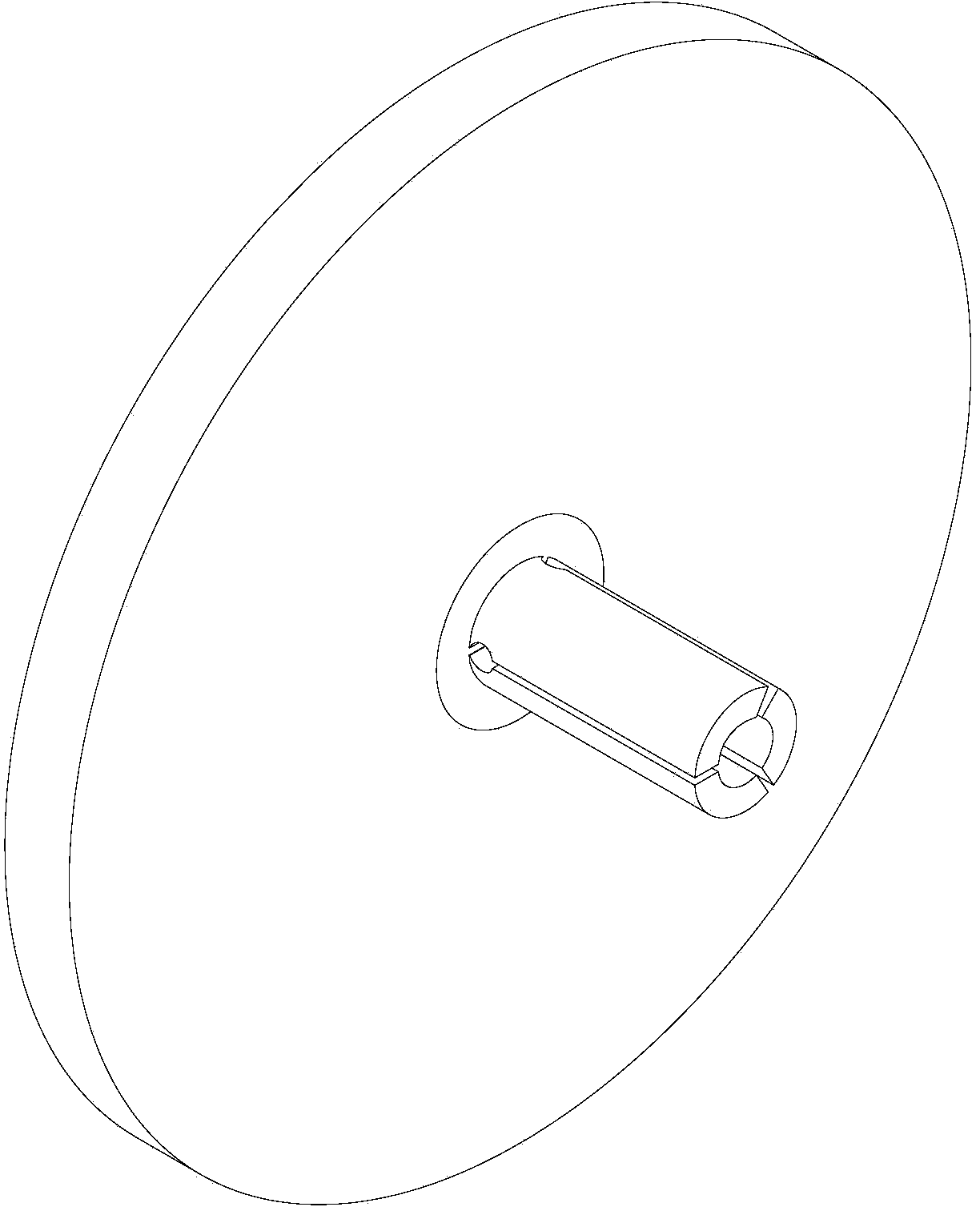

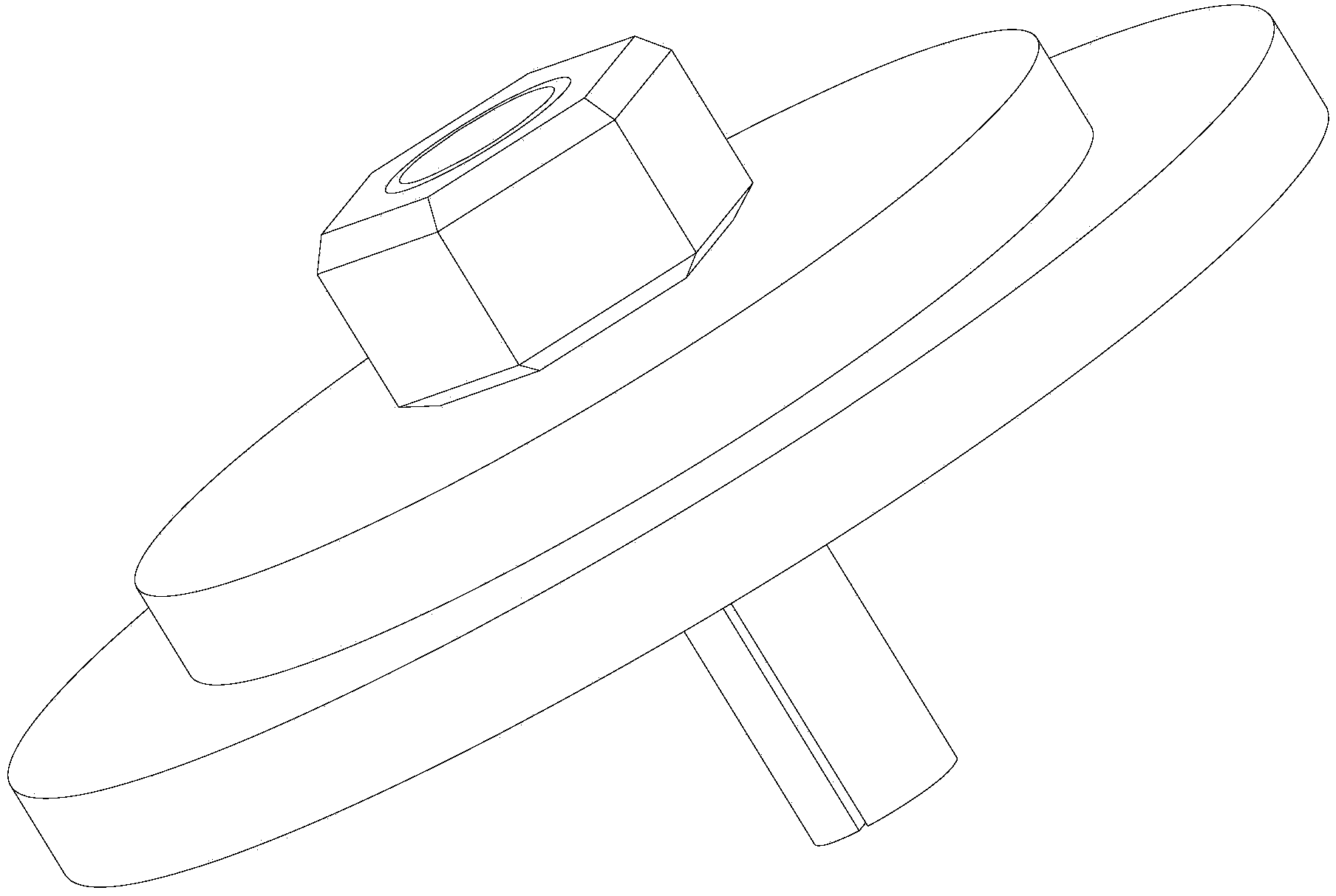

[0018] This embodiment relates to a fixture for processing plastic impellers of automobile engine water pumps, such as figure 1 , figure 2 and image 3 As shown, it includes: back board, tensioning column and screws. The tensioning column is composed of three tensioning pieces. There is a through hole in the center of the back board. Bolt head and external thread, the tensioning column is screwed and fixed through the external thread and the through hole of the back plate, the other end of the tensioning column is provided with internal thread, the screw is provided with external thread, and the screw is screwed into the tensioning column through its external thread When the internal thread is used, the diameter of the tightening column is increased. The fixture can be directly fixed on the chuck of the processing machine tool, or a fixing device, such as a slot, a fixing bolt, and a hoop, can be arranged on one side of the fixture, and the fixture can be further fixed on t...

Embodiment 2

[0020] A fixture for processing plastic impellers of automobile engine water pumps, including: a backrest plate, a tensioning column and screws, the tensioning column is composed of three tensioning pieces, and one end of the tensioning column is fixedly connected to the backrest plate by welding In the center, the other end of the tensioning column is provided with an internal thread, and the screw is provided with an external thread. When the screw is screwed into the internal thread of the tensioning column through its external thread, the diameter of the tensioning column is increased. The fixture can be directly fixed on the chuck of the processing machine tool, or a fixing device, such as a slot, a fixing bolt, and a hoop, can be arranged on one side of the fixture, and the fixture can be further fixed on the processing machine tool through these fixing devices. When using this fixture, by putting the inner hole of the plastic impeller of the automobile engine water pump ...

Embodiment 3

[0022] A fixture for processing plastic impellers of automobile engine water pumps, including: a backrest, a tensioning column and screws, the tensioning column is composed of two tensioning pieces, and one end of the tensioning column is fixedly connected to the backrest through bolt threads In the center of one side of the tensioning column, the other end of the tensioning column is provided with an internal thread, and the screw is provided with an external thread. When the screw is screwed into the internal thread of the tensioning column through its external thread, the diameter of the tensioning column is increased. This fixture can It can be directly fixed on the chuck of the processing machine tool, or a fixing device can be set on one side of the fixture, such as a card slot, a fixing bolt, and a clamp, and the fixture can be further fixed on the processing machine tool through these fixing devices; when using this fixture At this time, by putting the inner hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com