Resin-sealing molding apparatus

A technology of resin sealing and components, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of product quality degradation, lower sliding properties of frame components and bottom surface components, and limitation of package thickness, etc., to improve freedom degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

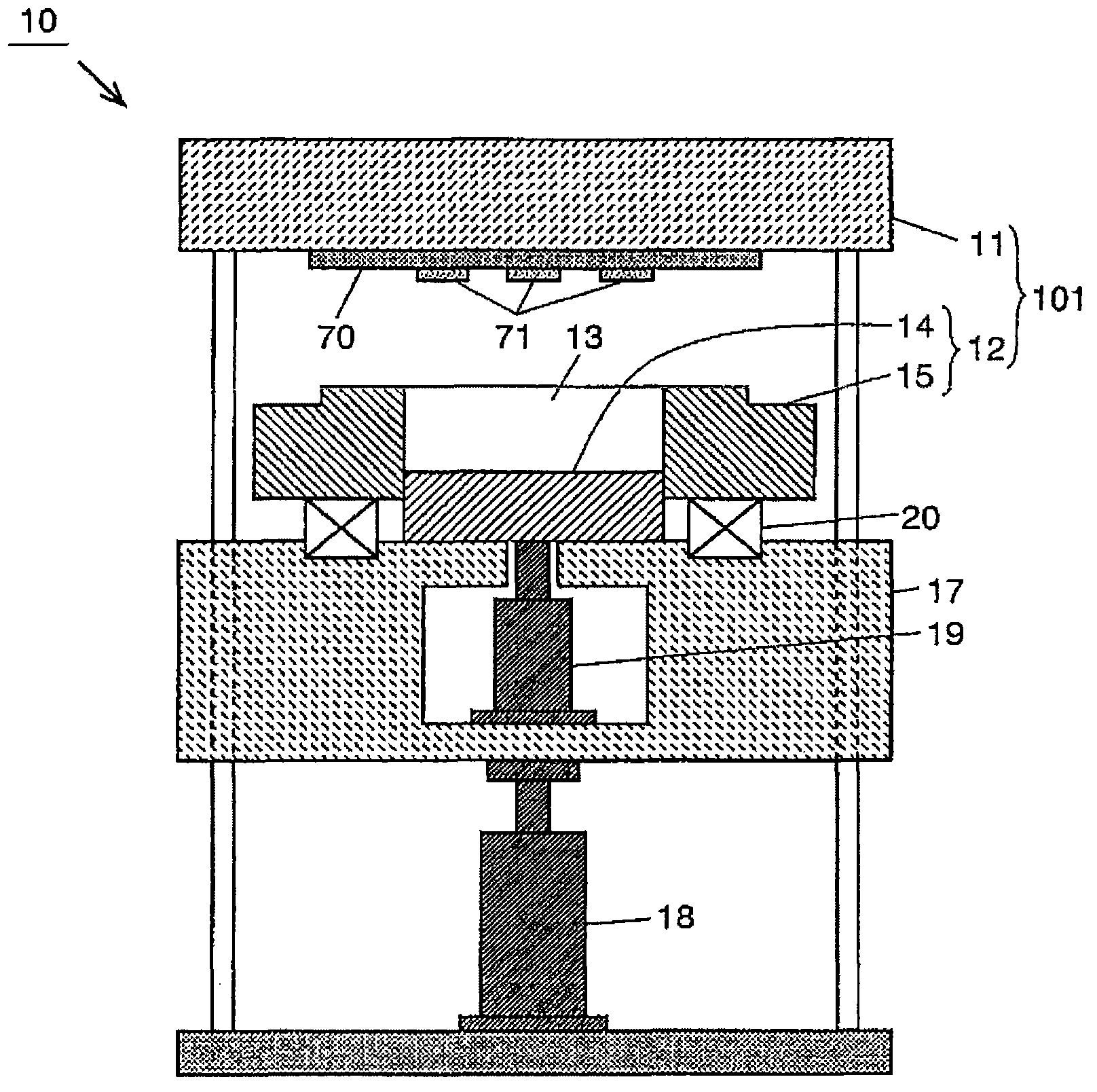

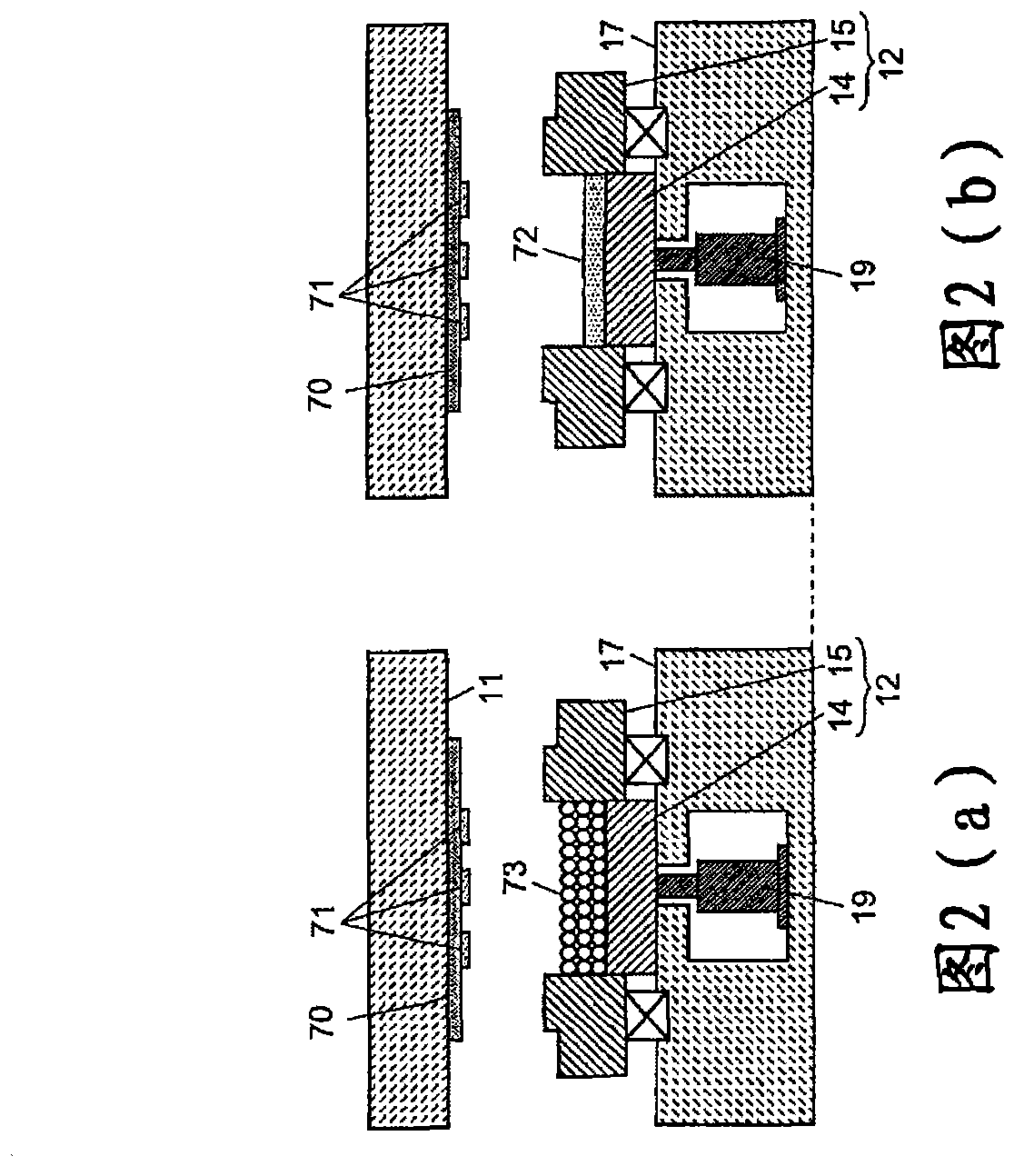

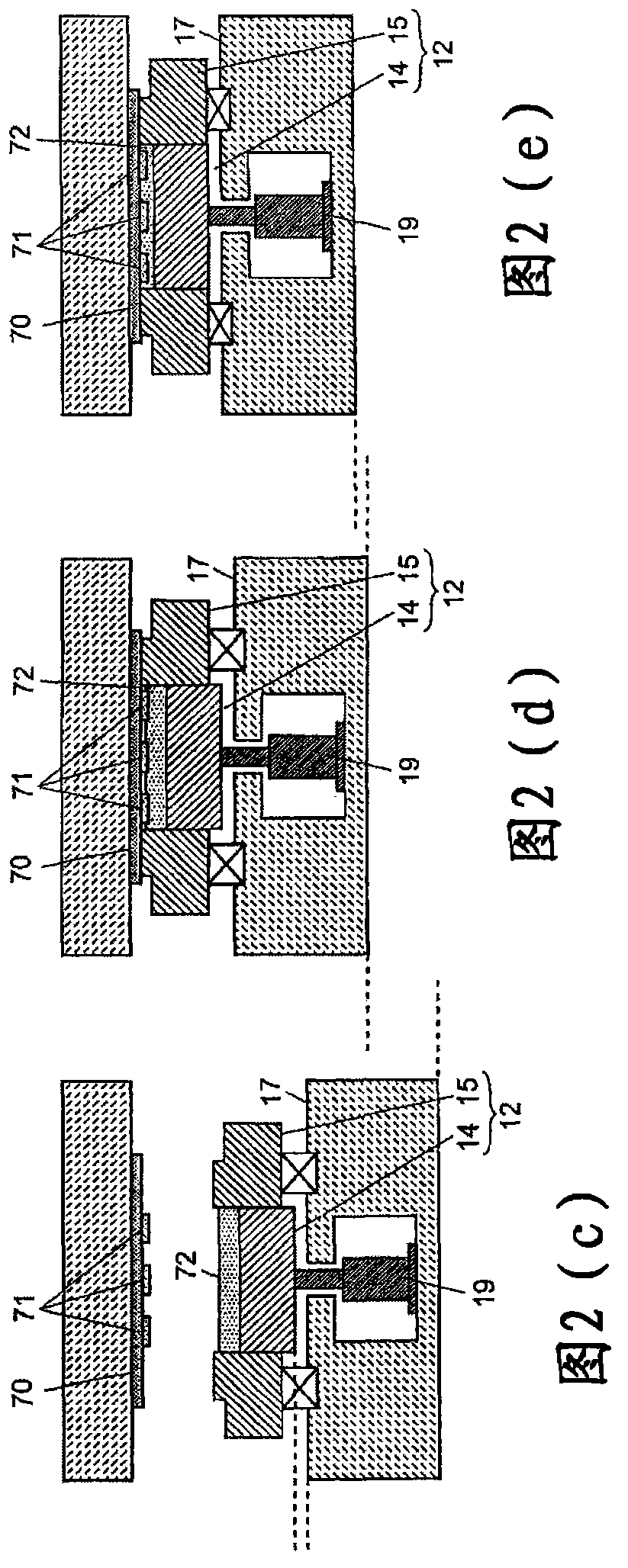

[0059] Below, refer to figure 1 ˜ FIG. 5 describe a first embodiment of the resin sealing molding apparatus for electronic components according to the present invention. The resin sealing molding device 10 of the present embodiment is as figure 1 As shown, it is equipped with: a resin sealing molding mold 101, which is composed of an upper mold 11 that holds a substrate 70 on which electronic components 71 such as semiconductor chips are mounted on the lower surface, and a lower mold 12 that is arranged opposite to the upper mold 11; The member 17 places the lower mold 12 and moves in the vertical direction. The pressing member 17 is driven vertically by a first drive mechanism 18 provided below the pressing member 17 .

[0060] The lower mold 12 is composed of a frame member 15 and a bottom member 14 that can slide up and down in the frame member 15, and can accommodate resin material in the space (cavity 13) surrounded by the frame member 15 and the bottom member 14. He...

Embodiment 2

[0070] Second, refer to Figure 6 ~ Figure 9 A second embodiment of the resin sealing molding apparatus for electronic components of the present invention will be described. The resin sealing molding apparatus 30 of this embodiment moves the frame member 15 up and down by the second drive mechanism 19 . The frame member 15 is connected to a connection member 32 , and the connection member 32 is connected to a frame-shaped movable plate 31 via an elastic member 33 . The movable plate 31 moves up and down by the second driving mechanism 19 placed inside the pressing member 17 ( Image 6 ). Other composition and figure 1 Similarly, the pressing member 17 is driven vertically by a first drive mechanism 18 (not shown) provided below the pressing member 17 .

[0071] The steps of resin sealing of electronic components using the resin sealing molding apparatus 30 described above will be described. First, as shown in FIG. 7( a ), the resin sealing mold 101 is opened, and the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com