Real silk cool fiber fabric and weaving method thereof

A technology for cool fibers and fabrics, applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of difficulty in forming, affecting wearing comfort, and high production and processing costs, and achieve the effect of improving moisture permeability and overcoming wrinkling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

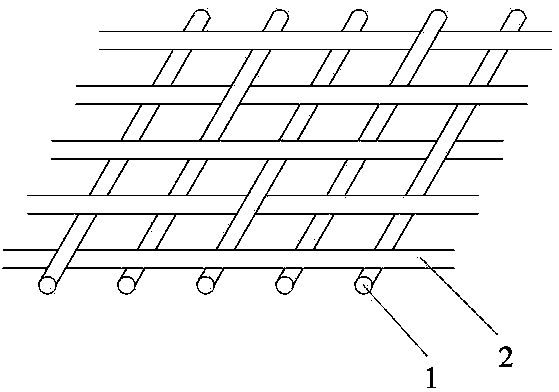

[0027] The fabric specifications are: warp: 2 / 20 / 22D mulberry silk; weft: 1 / 150D cool fiber (polyester filament / viscose filament 50 / 50), warp density: 130 threads / cm, weft density: 40 Roots / cm, five pieces of satin are used for weaving.

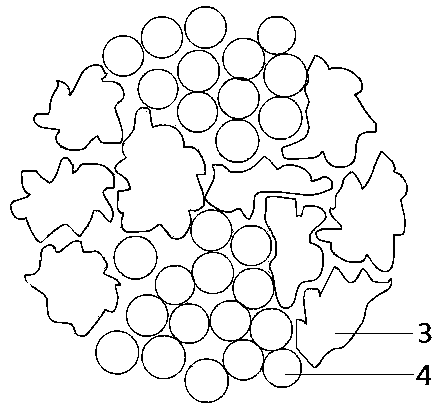

[0028] The cool fiber is a blend of polyester and viscose, specifically 75D polyester filament + 75D viscose filament.

[0029] Its manufacturing process is: dipping - winding - doubling - twisting - shaping - rewinding - warping - weaving - finishing.

[0030] The fabric is woven on a rapier loom at a speed of 280 rpm.

[0031] The fabric is dyed into various colors by conventional process using reactive dyes.

[0032] Select pure silk fabrics with the same parameters for comparison. After testing, the moisture permeability rate WVT of this icy fabric is 330.742g / m 2 .h, better than 314.814g / m of silk fabric 2 .h; thermal resistance is 4.71 (10 -3 m 2 .K / W), less than 5.04(10 -3 m 2 .K / W), the former has good thermal conductivity; th...

Embodiment 2

[0034] The fabric specifications are: warp: 2 / 20 / 22D mulberry silk; weft: 1 / 150D cool fiber (polyester filament / viscose filament 50 / 50), warp density: 50 threads / cm, weft density: 25 Roots / cm, five pieces of satin are used for weaving.

[0035] The cool fiber is a blend of polyester and viscose, specifically 75D polyester filament + 75D viscose filament.

[0036] Its manufacturing process is: dipping - winding - doubling - twisting - shaping - rewinding - warping - weaving - finishing.

[0037] The fabric is woven on a rapier loom at a speed of 220 rpm.

[0038] The fabric is dyed into various colors by conventional process using reactive dyes.

[0039] Choose pure silk fabrics with the same parameters for comparison. After testing, the moisture permeability rate WVT of this icy fabric is 350.742g / m 2 .h, better than 314.814g / m of silk fabric 2 .h; thermal resistance is 4.91 (10 -3 m 2 .K / W), less than 5.04(10 -3 m 2 .K / W), the former has good thermal conductivity; the...

Embodiment 3

[0041]The fabric specifications are: warp: 2 / 20 / 22D mulberry silk; weft: 1 / 150D cool fiber (polyester filament / viscose filament 50 / 50), warp density: 150 threads / cm, weft density: 45 Roots / cm, five pieces of satin are used for weaving.

[0042] The cool fiber is a blend of polyester and viscose, specifically 75D polyester filament + 75D viscose filament.

[0043] Its manufacturing process is: dipping - winding - doubling - twisting - shaping - rewinding - warping - weaving - finishing.

[0044] The fabric is woven on a rapier loom at a speed of 300 rpm.

[0045] The fabric is dyed into various colors by conventional process using reactive dyes.

[0046] Select pure silk fabrics with the same parameters for comparison. After testing, the moisture permeability rate WVT of this icy fabric is 325.742g / m 2 .h, better than 314.814g / m of silk fabric 2 .h; thermal resistance is 4.61 (10 -3 m 2 .K / W), less than 5.04(10 -3 m 2 .K / W), the former has good thermal conductivity; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com