Raw crease-resistant viscose spinning solution and fiber and preparation method

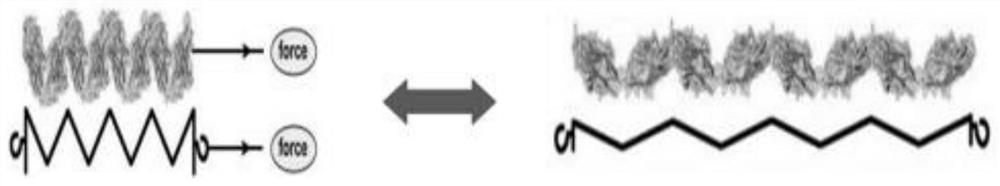

A technology for spinning dope and viscose fiber, applied in the field of viscose fiber manufacturing, can solve the problems of easy wrinkling and deformation, and achieve the effects of good mechanical properties, good wrinkle resistance and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

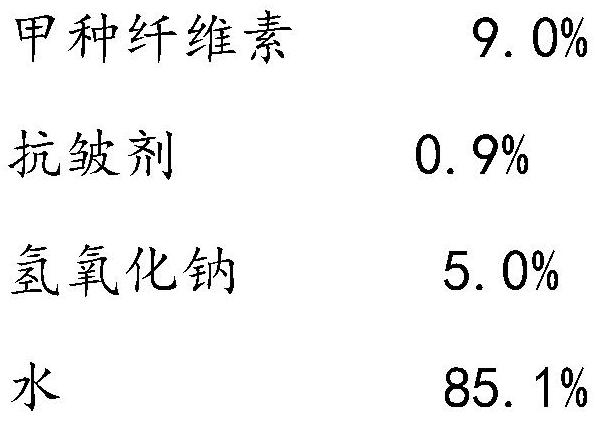

[0029] Prepare the viscose spinning stock solution according to the ordinary viscose fiber production process, take 10 kg of the viscose spinning stock solution, add anti-wrinkle agent, and ensure that the composition ratio is:

[0030]

[0031] The anti-wrinkle agent adopts urea-formaldehyde resin, which is added to the viscose spinning stock solution according to 10% of the mass of the first type of cellulose, which is equivalent to 0.9% of the mass of the system. Shaping, drafting, cutting, refining, and high-temperature drying to obtain native anti-wrinkle viscose staple fibers.

Embodiment 2

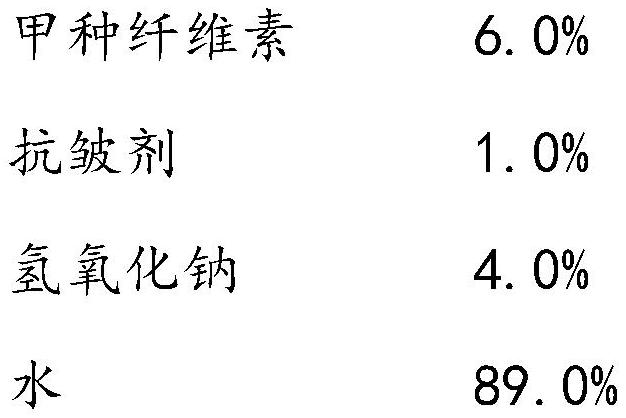

[0033] Prepare the viscose spinning stock solution according to the ordinary viscose fiber production process, take 10 kg of the viscose spinning stock solution, add anti-wrinkle agent, and ensure that the composition ratio is:

[0034]

[0035]The anti-wrinkle agent adopts dimethylol dihydroxyethylene urea, which is added to the viscose spinning stock solution according to 16.7% of the mass of the first cellulose, which is equivalent to 1% of the mass of the system, mixed evenly, and transported to the spinning In the silk section, it is shaped, drawn, cut, refined, and dried at high temperature according to the ordinary viscose fiber spinning process to obtain the original anti-wrinkle viscose staple fiber.

Embodiment 3

[0037] Prepare viscose spinning stock solution according to common viscose fiber production process, get 10 kilograms of viscose spinning stock solution, add anti-wrinkle agent and catalyst, ensure that its composition ratio is:

[0038]

[0039]

[0040] The anti-wrinkle agent adopts 1,2,3,4-butane tetracarboxylic acid, which is added to the spinning stock solution according to 10% of the mass of the first cellulose, which is equivalent to 0.9% of the mass of the system, and the catalyst is sodium phosphite. It is added to the viscose spinning stock solution according to 0.1% of the system quality, mixed evenly, transported to the spinning section, and shaped according to the ordinary viscose fiber spinning process, drafted, cut, refined, and dried at high temperature to obtain raw Wrinkle-resistant viscose staple fiber.

[0041] The anti-wrinkle agent can be a multi-component mixture or a single component. The anti-wrinkle agent used in this example is 1,2,3,4-butane t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com