Leno hemming device

A leno hemming and leno technology, which is applied in the field of leno hemming devices in two warps, can solve the problems of large and complex structures, high costs, and complicated mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In this article, "left" and "right" refer to the left-hand side and right-hand side of a person facing the loom and standing in front of the loom, respectively, and "upper opening position" refers to the position of the shed triangle when the shed is opened to the maximum. The position of the upper line or the position of the corresponding components, "the position of the lower opening" refers to the position of the lower line of the shed triangle or the position of the corresponding components when the shed is opened to the maximum.

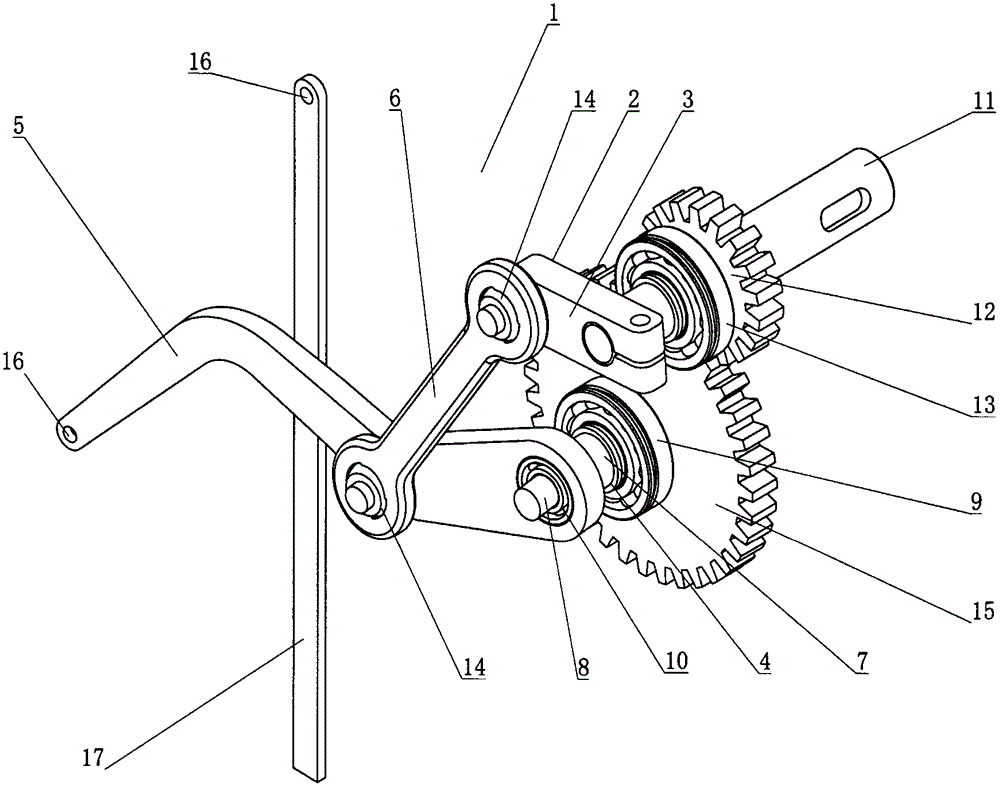

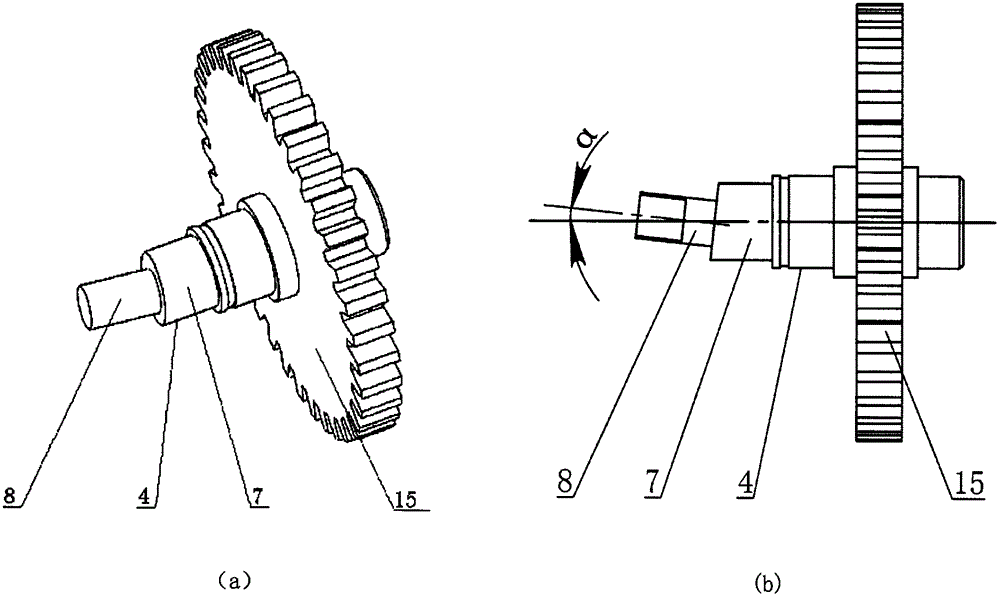

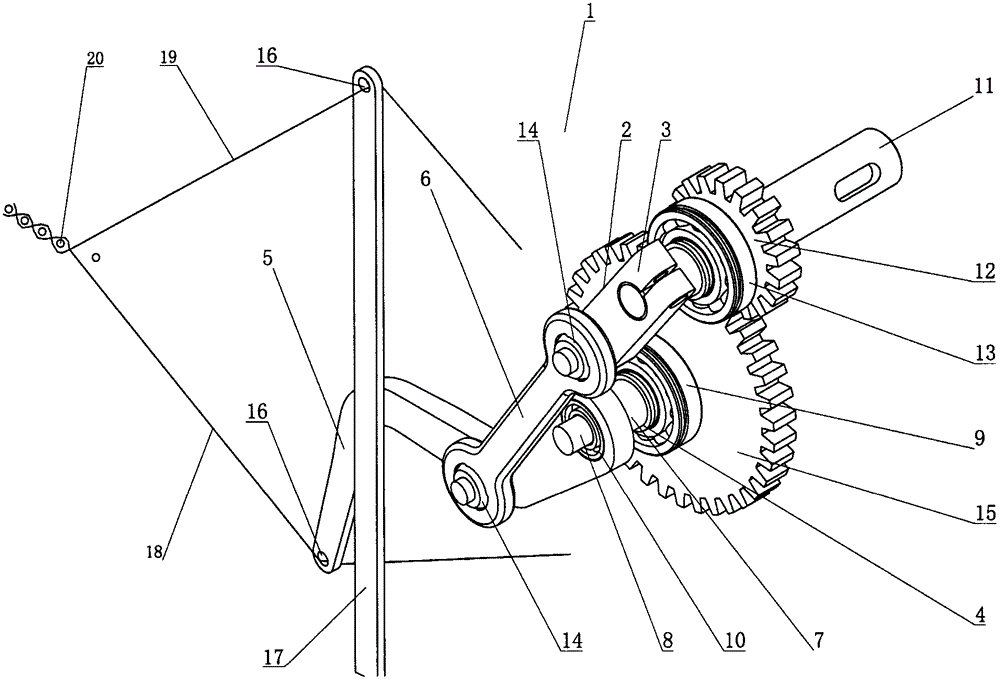

[0038] Such as figure 1 Shown in Fig. 3 is the first embodiment of the present invention, in this embodiment, leno hemming device 1 comprises a set of space link mechanism 2, and space link mechanism 2 comprises crank 3, bending shaft 4, Swing torsion bar 5 and connecting rod 6. Such as figure 2 As shown, the bending shaft 4 includes the main shaft 7, the auxiliary shaft 8, and the bending shaft gear 15. The axis line of the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com