Fabricated electronic workshop and construction method thereof

An electronic factory building and assembly technology, which is applied in the direction of industrial buildings, buildings, building structures, etc., can solve the problems of slow construction speed, unstable quality, low economy, etc., achieve less labor, reduce the number of laborers, and solve the construction speed slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

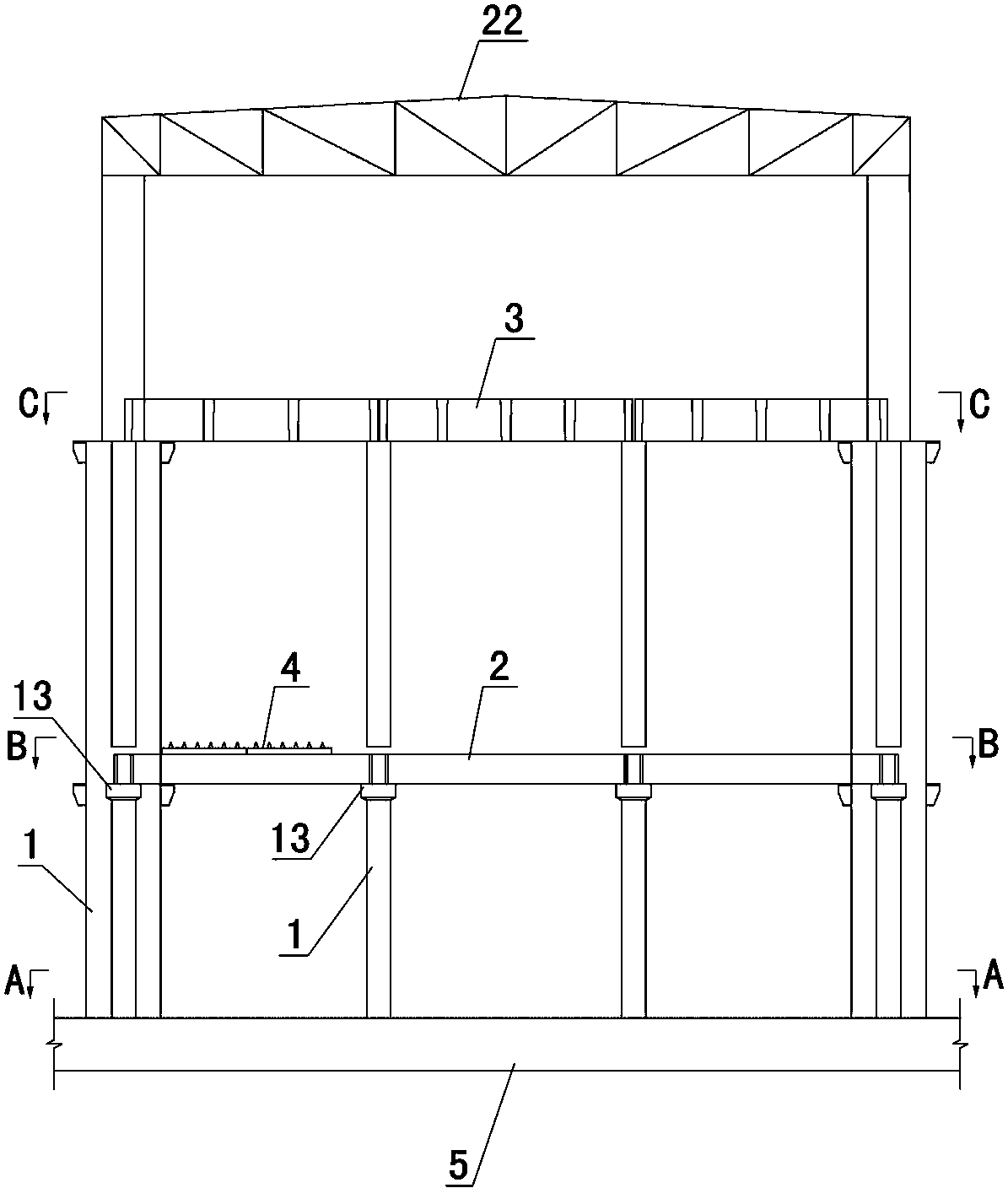

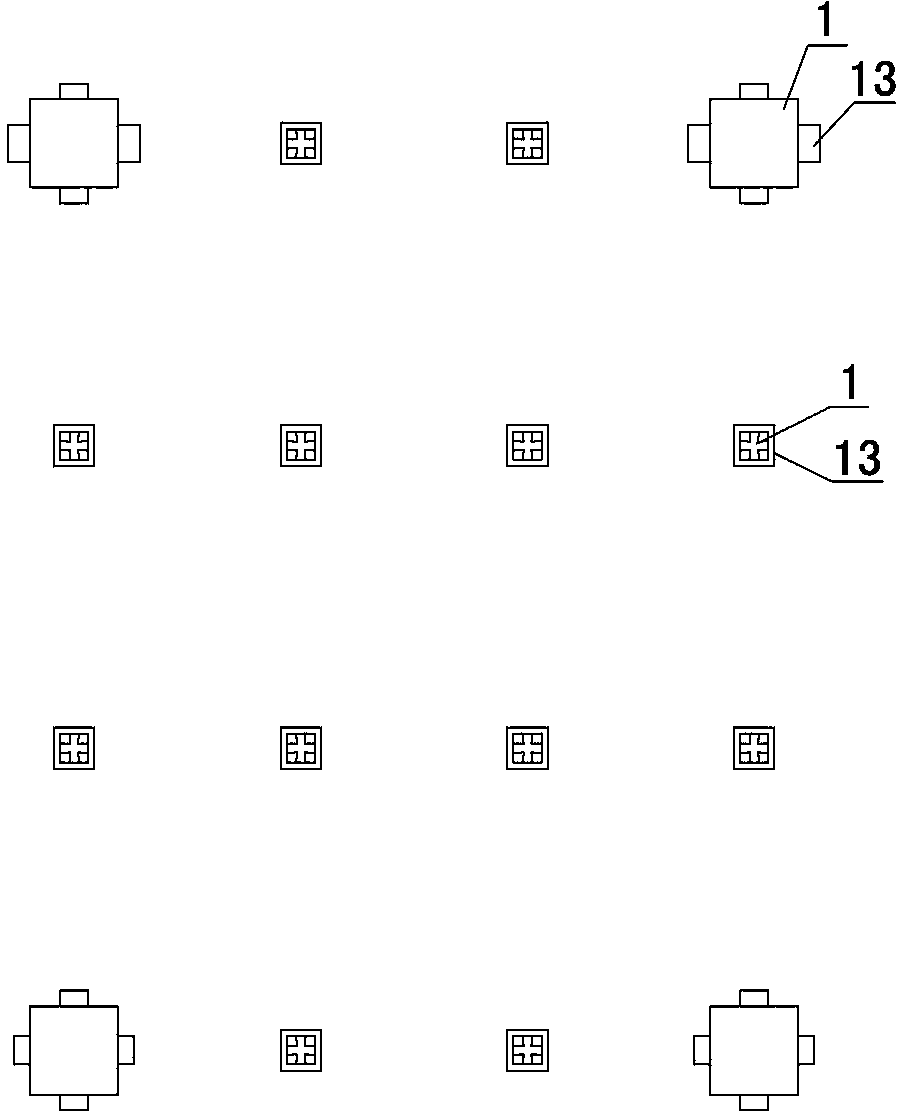

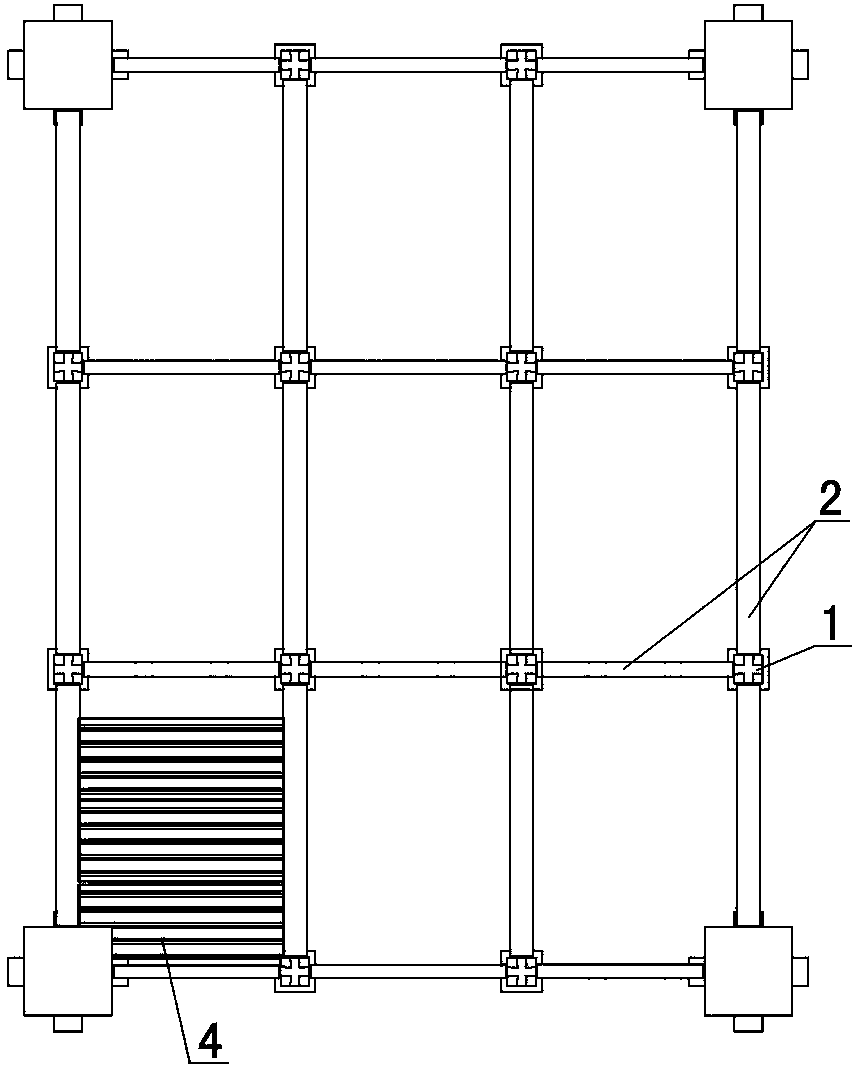

[0035] Examples see Figure 1-4 As shown, this prefabricated electronic factory building includes factory building foundation raft 5 , prefabricated column 1 of reinforced concrete structure, prefabricated composite beam 2 of reinforced concrete structure, prefabricated lattice beam 3 of reinforced concrete structure and roof structure 22 .

[0036] see Figure 5 , In this embodiment, the prefabricated column 1 is provided with support fixing bolts 9 , safety net fixing bolts 10 and prefabricated column lifting points 8 . When the prefabricated column is produced in the factory, the prefabricated column lifting point 8, the support fixing bolt 9 and the safety net fixing bolt 10 are pre-embedded. The prefabricated column lifting point 8 is used for hoisting the prefabricated column to facilitate demoulding and lifting of the precast column, and the supporting fixing bolt 9 Used for temporary fixing of prefabricated column installation, safety net fixing bolts 10 are used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com