Online detection method for oil pipe field

A detection method and oil pipe technology, which is applied in the field of oil and gas field exploration and development, can solve the problems of high cost and long cycle of oil pipe detection methods, and achieve the effects of improving safety and timeliness, low operating cost, and reducing operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

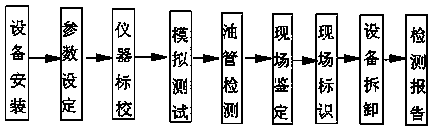

[0025] Such as figure 1 As shown, the on-line detection method of a kind of oil pipe scene provided by the present invention comprises the following steps:

[0026] (1) Equipment installation: Install the tubing detector on the wellhead flange plane with wellhead flange screws, then use a dedicated 12-core cable to connect the tubing detector to the control panel, and then connect the control panel to the computer through a USB communication line ;

[0027] (2) Parameter setting: turn on the computer, open the on-site tubing inspection application software, enter the well number and inspection date to be inspected in the dialog box that pops up, and confirm. Click "Settings" on the detection interface, select the appropriate "Detection Specifications", and then set the critical value of the first type of alarm (pipe wall hole) and the second type of alarm (wall thickness);

[0028] (3) Instrument calibration: Run a brand-new tubing pup joint of about 2 meters in the well wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com