Refraction and reflection light emitting device

A technology of catadioptric and light devices, which is applied in the field of catadioptric light emitting devices, can solve the problems of affecting the service life of LEDs, increasing the number of PCB boards, and the number of LEDs used, so as to improve the picture quality and reduce the number of LEDs used , the effect of increasing the irradiated area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

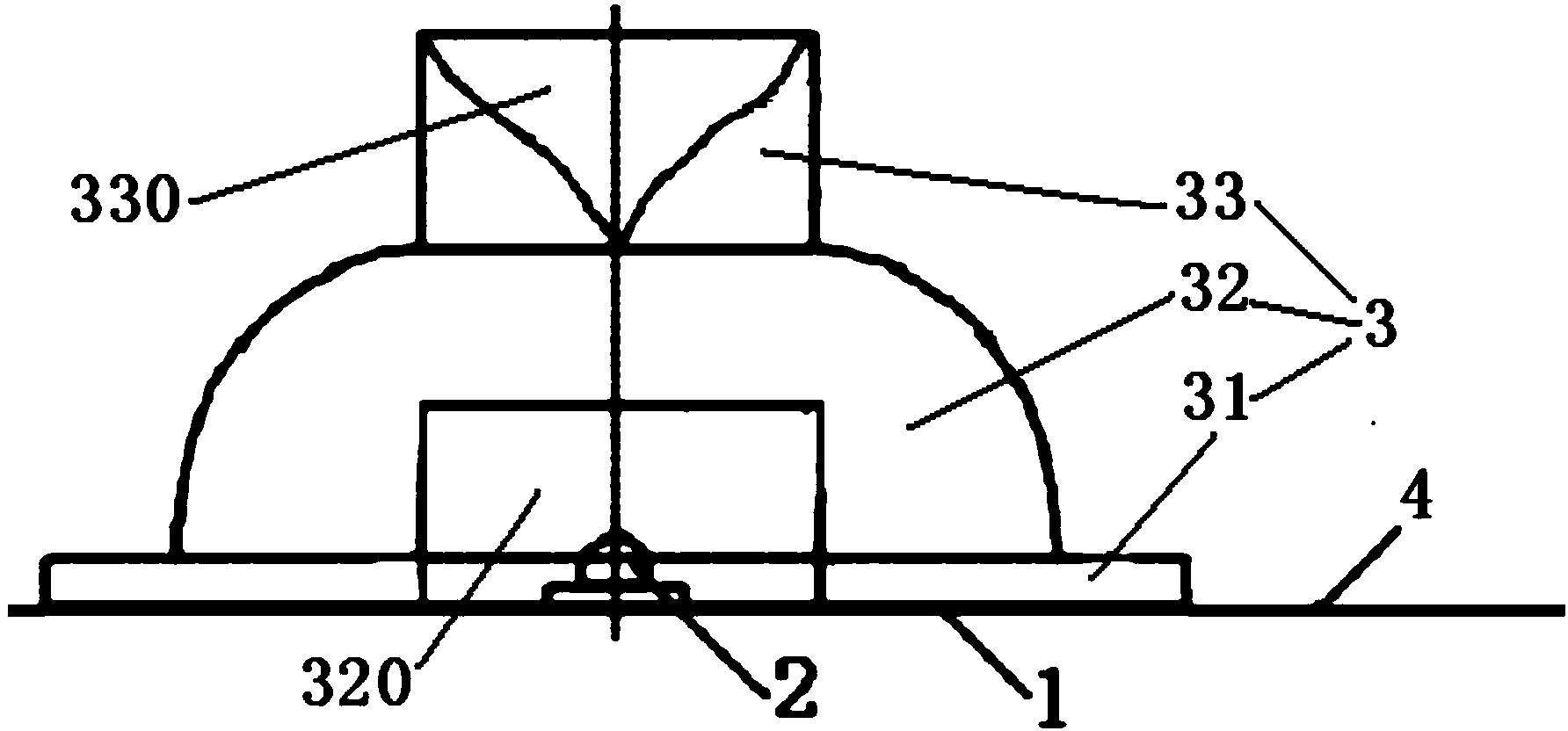

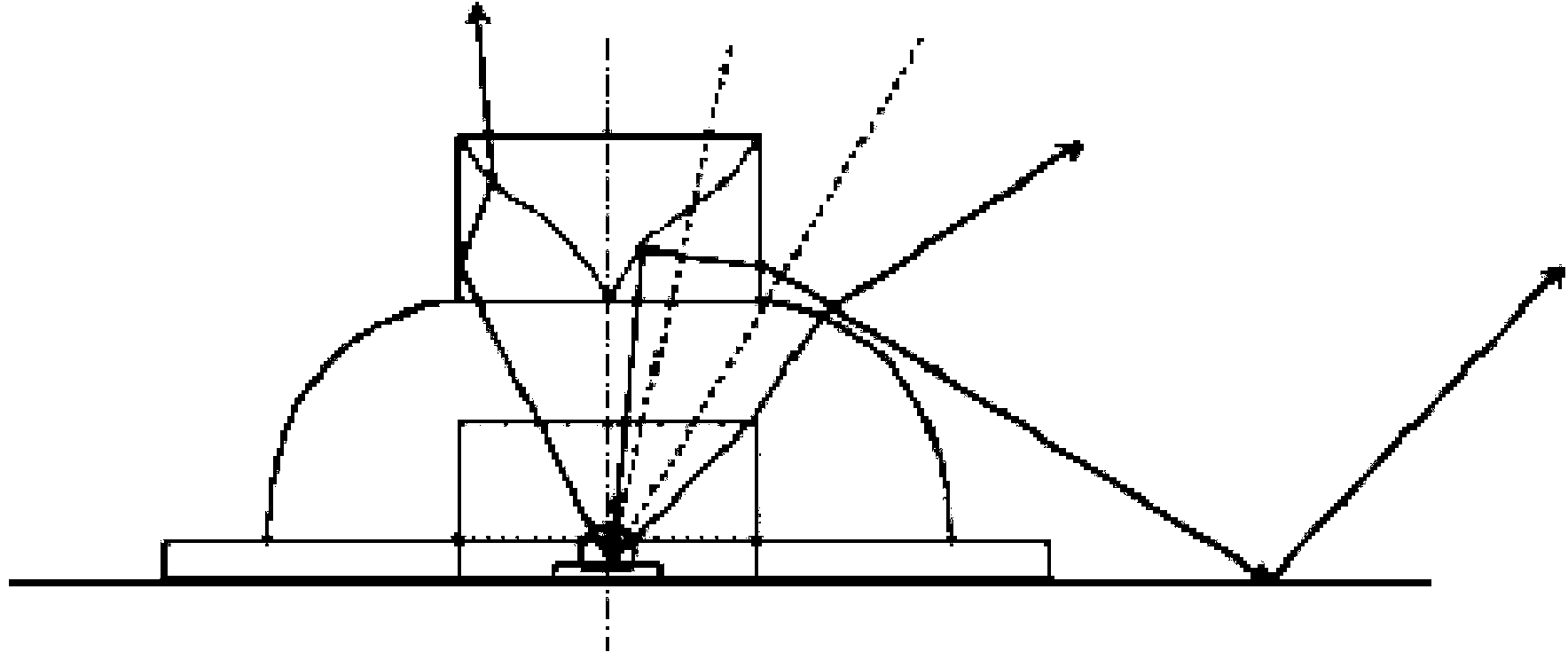

[0040] Example 1 Build a backlight module for a 32-inch backlight LCD TV

[0041] Such as Figure 4 As shown, using 10 LED light sources of 3W each, each LED light source cooperates with the large-angle catadioptric optical lens of the present invention, and the large-angle catadioptric optical lens divides the light emitted by the LED light source into three parts for processing respectively. The light emitted by the LED light source and its optical axis at an angle greater than 30° and not greater than 90° is refracted and incident on the diffuser plate, and the light emitted by the LED light source and its optical axis at an angle greater than 12° and not greater than 30° Through reflection and double refraction, the light facing the LED light source is formed. The light emitted by the LED light source and its optical axis within the range of an angle greater than 0° and not greater than 12° passes through reflection, refraction, and secondary reflection of the reflective s...

example 2

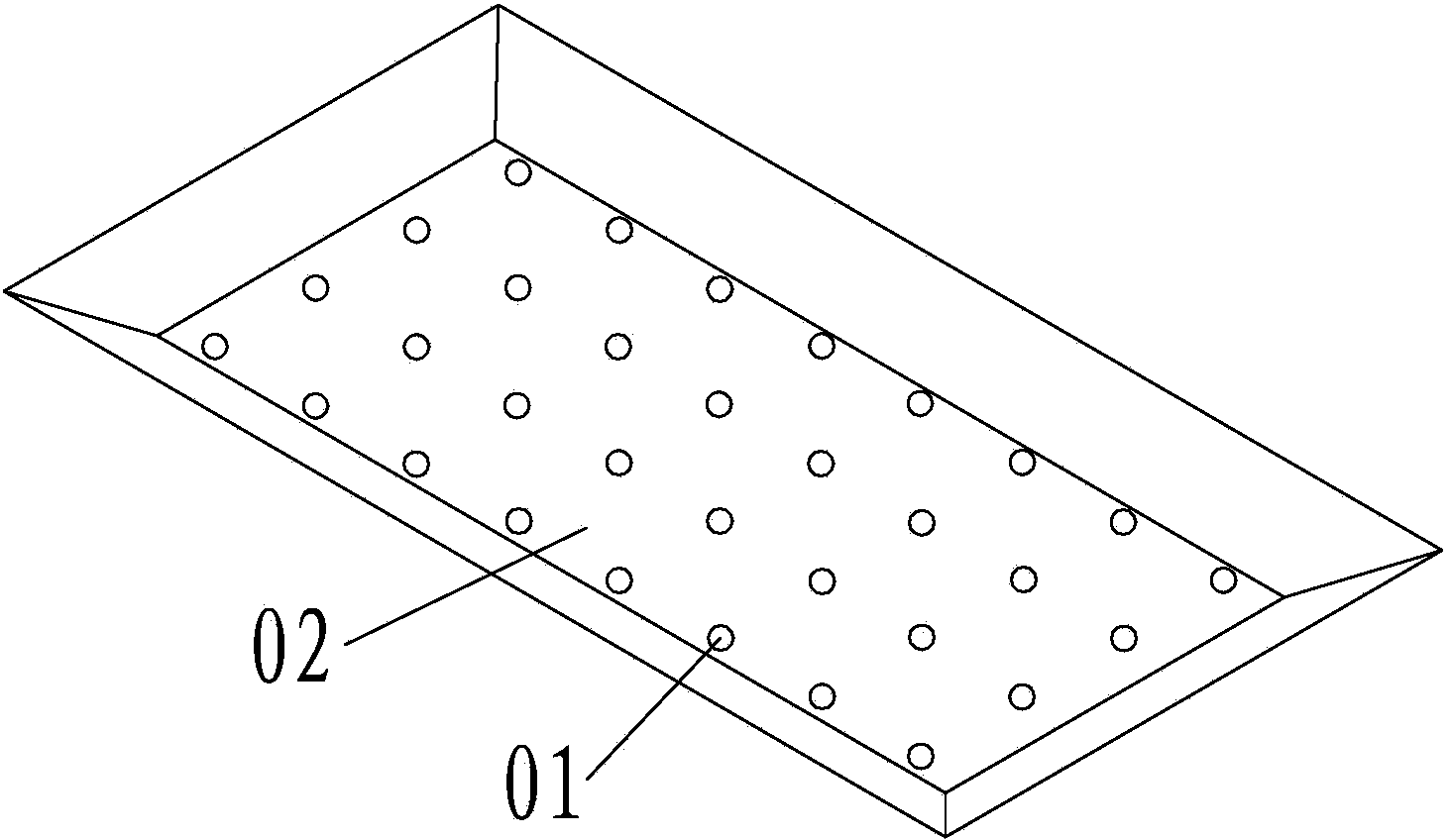

[0042] Example 2 Build a 10w panel light

[0043] Such as Figure 5 As shown, by using five 2W LED light sources, combined with the catadioptric optical lens and high reflectivity reflective sheet of the present invention, an efficient 10w panel light can be constructed.

[0044] Compared with the existing direct-type LED backlight module, the direct-type LED backlight module of the present invention has the following advantages:

[0045](1) The required number of LEDs can be reduced. For example, for 32-inch backlight products, the original 20-30 LEDs can be reduced to 10 or even less, thereby increasing the Pitch value and reducing the duty cycle. reduced costs;

[0046] (2) Due to the use of fewer LEDs, the consistency of LED light color can be better controlled and the picture quality of backlight products can be improved;

[0047] (3) Due to the use of high-reflectivity reflective sheets combined with catadioptric optical lenses for secondary reflection, the utilizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com