Split control anti-freezing gas water heater

A hot water machine, gas technology, applied in the direction of fluid heaters, mechanical equipment, water heaters, etc., can solve the problems of large power consumption, difficult maintenance, troublesome operation, etc., to prevent freezing, easy to use, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

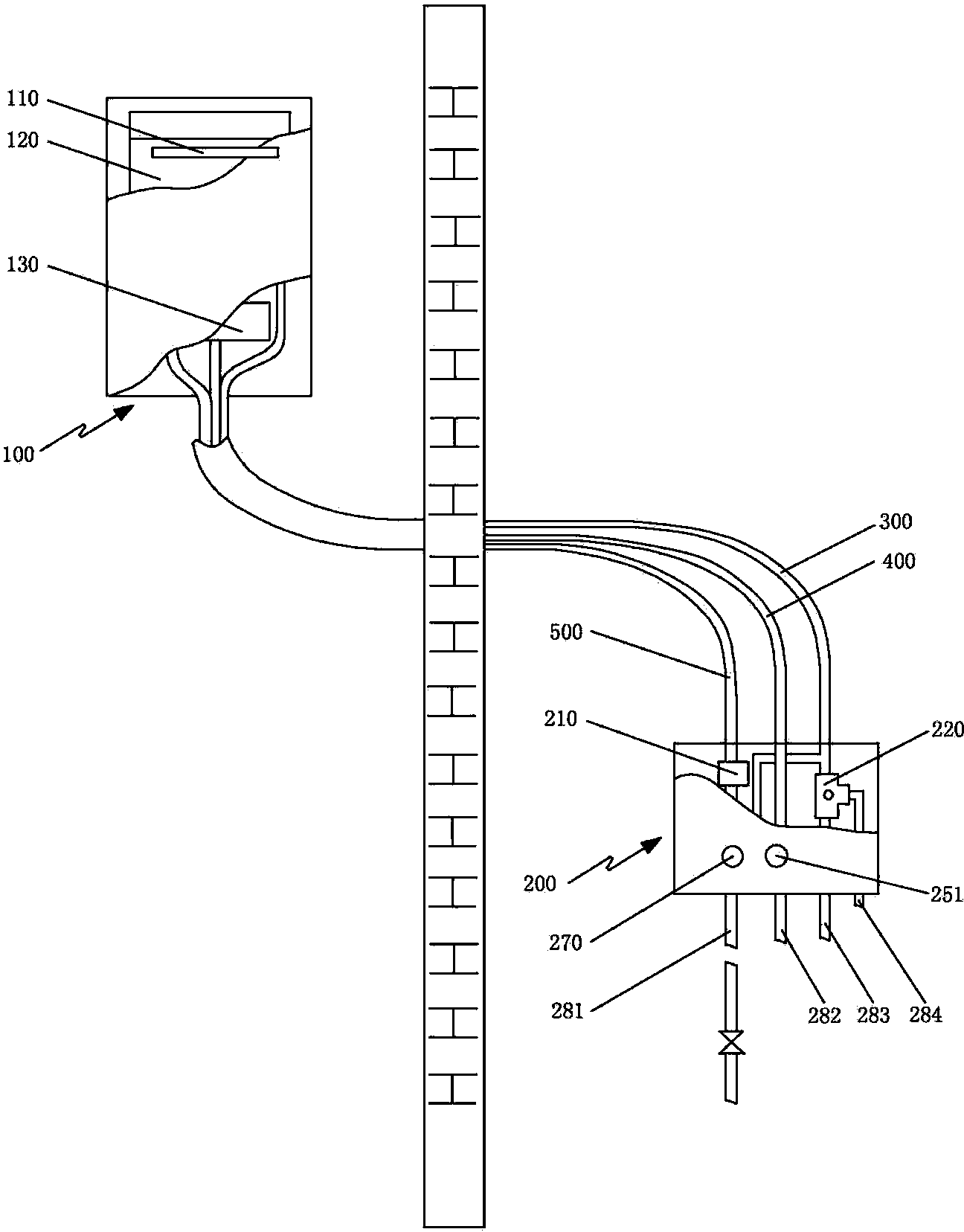

[0022] Example 1 Separate control antifreeze type gas water heater (combined type)

[0023] Such as Figure 1 to Figure 7 As shown, the split control antifreeze type gas water heater (combined type) is composed of a main machine (100) and an auxiliary machine (200), and the main machine (100) and the auxiliary machine (200) are of a split structure.

[0024] The host is provided with a smoke exhaust port (110), a heat exchanger (120) and a burner (130).

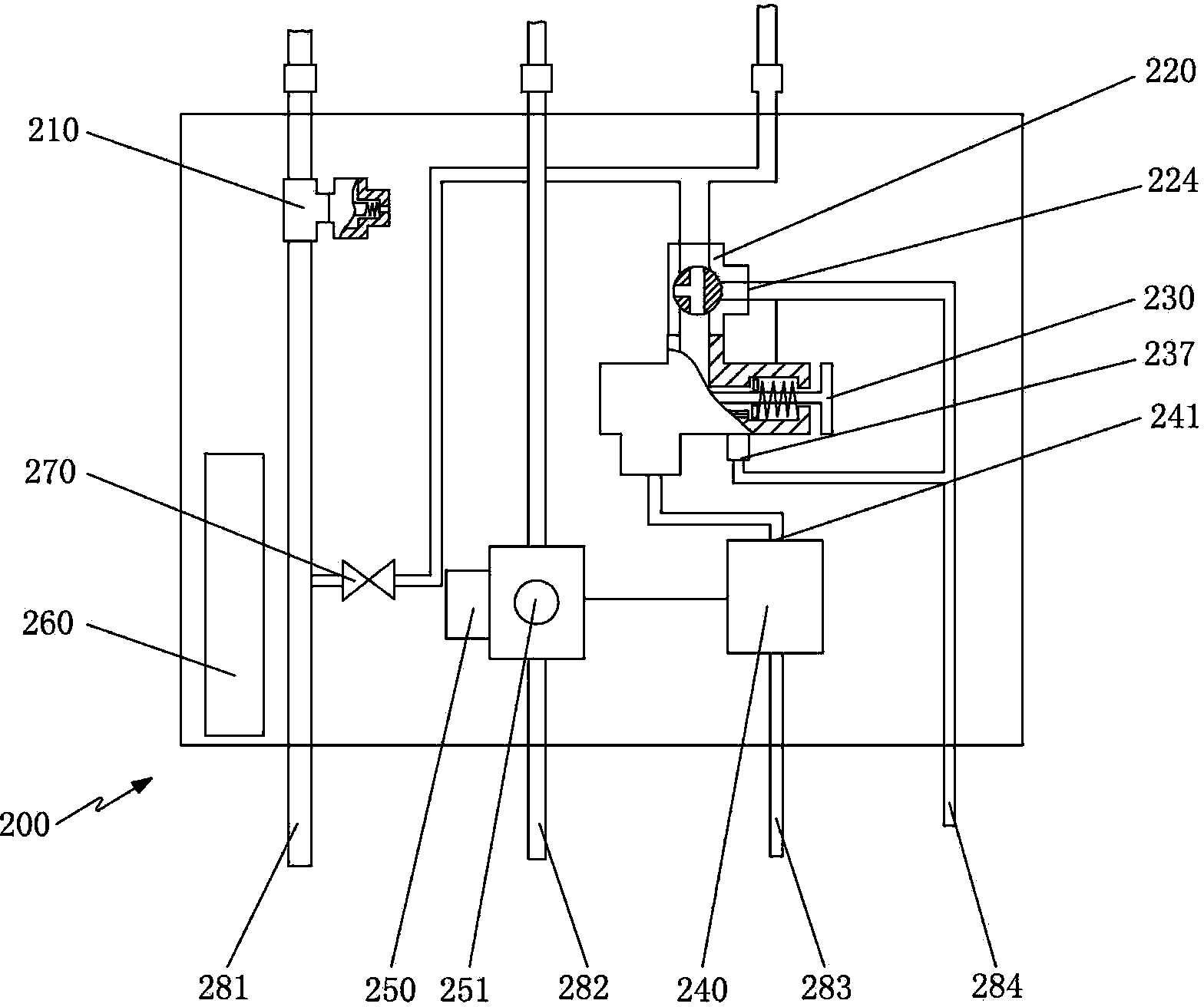

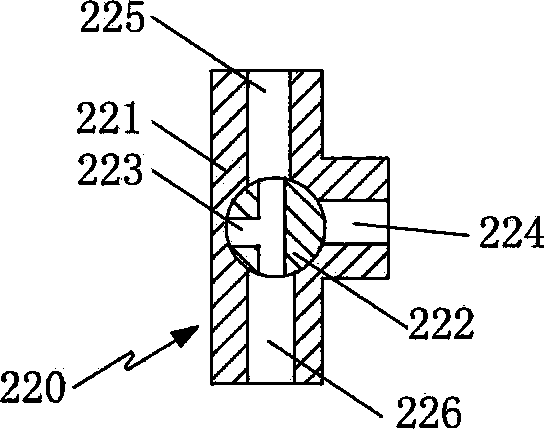

[0025] The structure of the auxiliary machine (200) is: an automatic replacement valve (210) is installed on the pipeline of the water outlet pipe (281); a gas solenoid valve (250) is installed on the pipeline of the gas pipe (282), and a There is a gas adjustment knob (251); a water control device (240) is installed on the water inlet pipe (283), and the outlet (241) of the water control device (240) is connected to an automatic drainage device (230) and a manual drainage device in sequence (220), drain port I (224) of t...

Embodiment 2

[0035] Example 2 Split control antifreeze type gas water heater (manual type)

[0036] Such as Figure 8 As shown, the split control antifreeze type gas water heater (manual type) is composed of a main machine (100) and an auxiliary machine (200), and the main machine (100) and the auxiliary machine (200) are of a split structure.

[0037] Other structures are the same as in Embodiment 1, the difference is that: in the auxiliary machine (200), a water control device (240) is installed on the water inlet pipe (283), and only the outlet (241) of the water control device (240) Connect the manual drainage device (220), the water outlet (225) of the manual drainage device (220) is connected to the water inlet connection pipe (300), the drain port I (224) of the manual drainage device (220) is connected to the overflow pipe (284) connect.

Embodiment 3

[0038] Example 3 Split control antifreeze type gas water heater (automatic type)

[0039] Such as Figure 9 As shown, the split control antifreeze type gas water heater (automatic type) is composed of a main machine (100) and an auxiliary machine (200), and the main machine (100) and the auxiliary machine (200) are of a split structure.

[0040] Other structures are the same as in Embodiment 1, the difference is that: in the auxiliary machine (200), a water control device (240) is installed on the water inlet pipe (283), and only the outlet (241) of the water control device (240) Connect the automatic drain device (230), the water outlet (239) of the automatic drain device (230) is directly connected with the water inlet connection pipe (300), the drain port II (237) of the automatic drain device (230) is connected with the overflow pipe (284 )connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com