Calibration method of coolant filling equipment

A technology of filling equipment and calibration method, which is applied in the field of calibration of refrigerant filling equipment, can solve the problems of non-recyclable refrigerant, complicated calibration procedures, and low degree of automation, and achieve the goals of reducing weight, improving automation, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

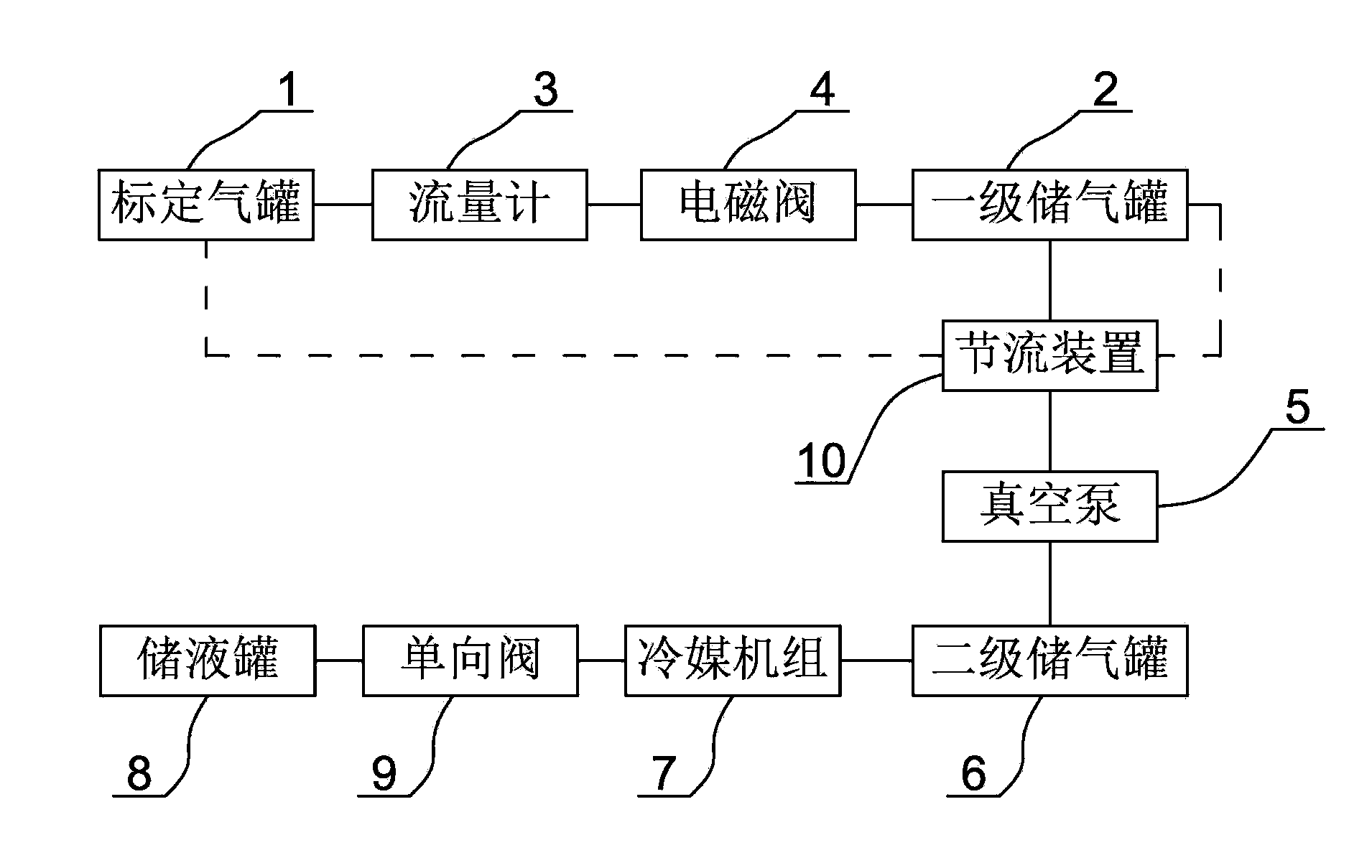

[0043] A method for calibrating refrigerant filling equipment of the present invention, the calibrating system it adopts is as follows: figure 1 As shown, it specifically includes the following steps:

[0044] a. Set the refrigerant charging amount of the refrigerant charging machine according to the design standard of refrigerant charging, for example, the refrigerant charging amount of a general car is about 460 grams;

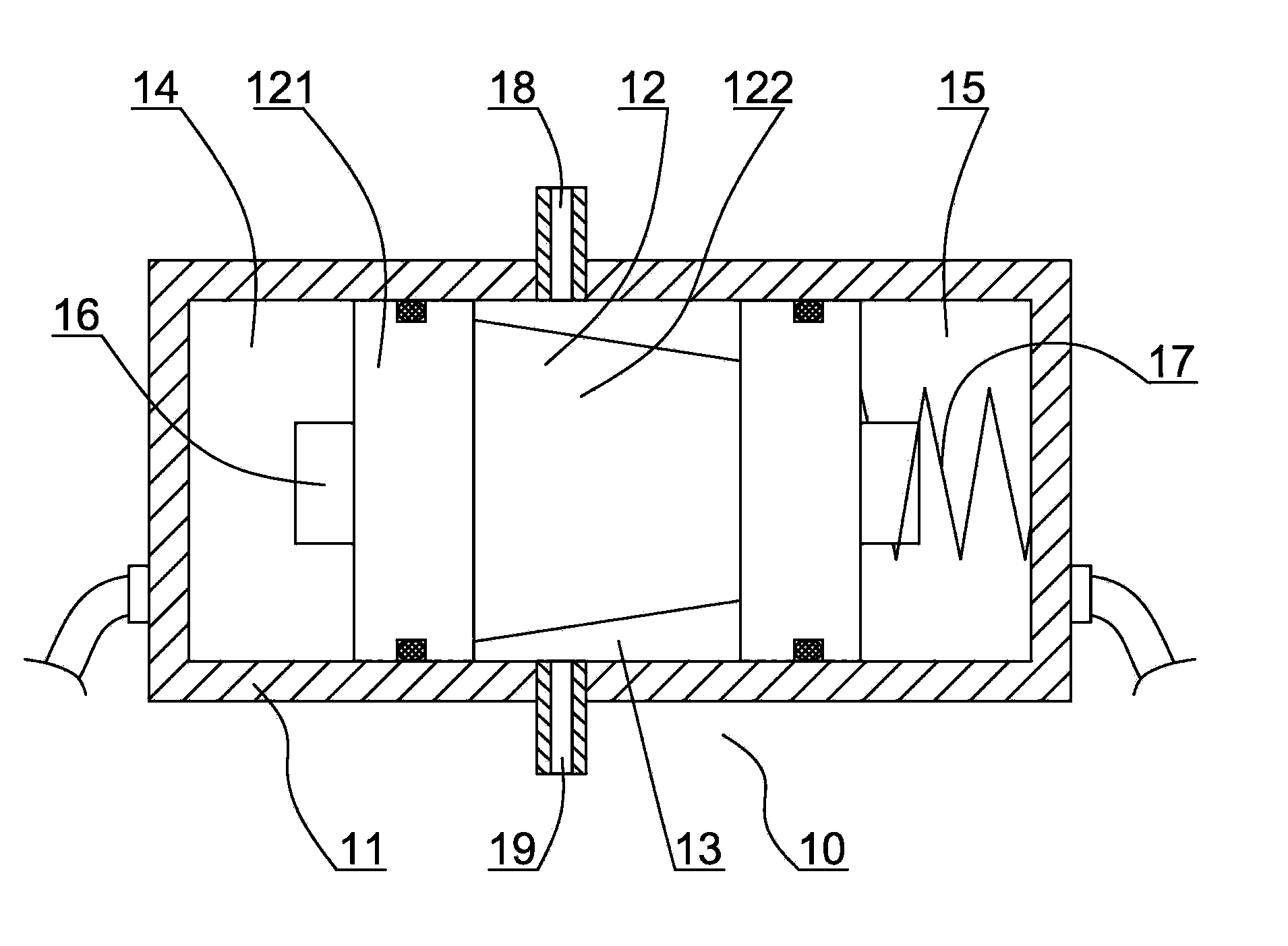

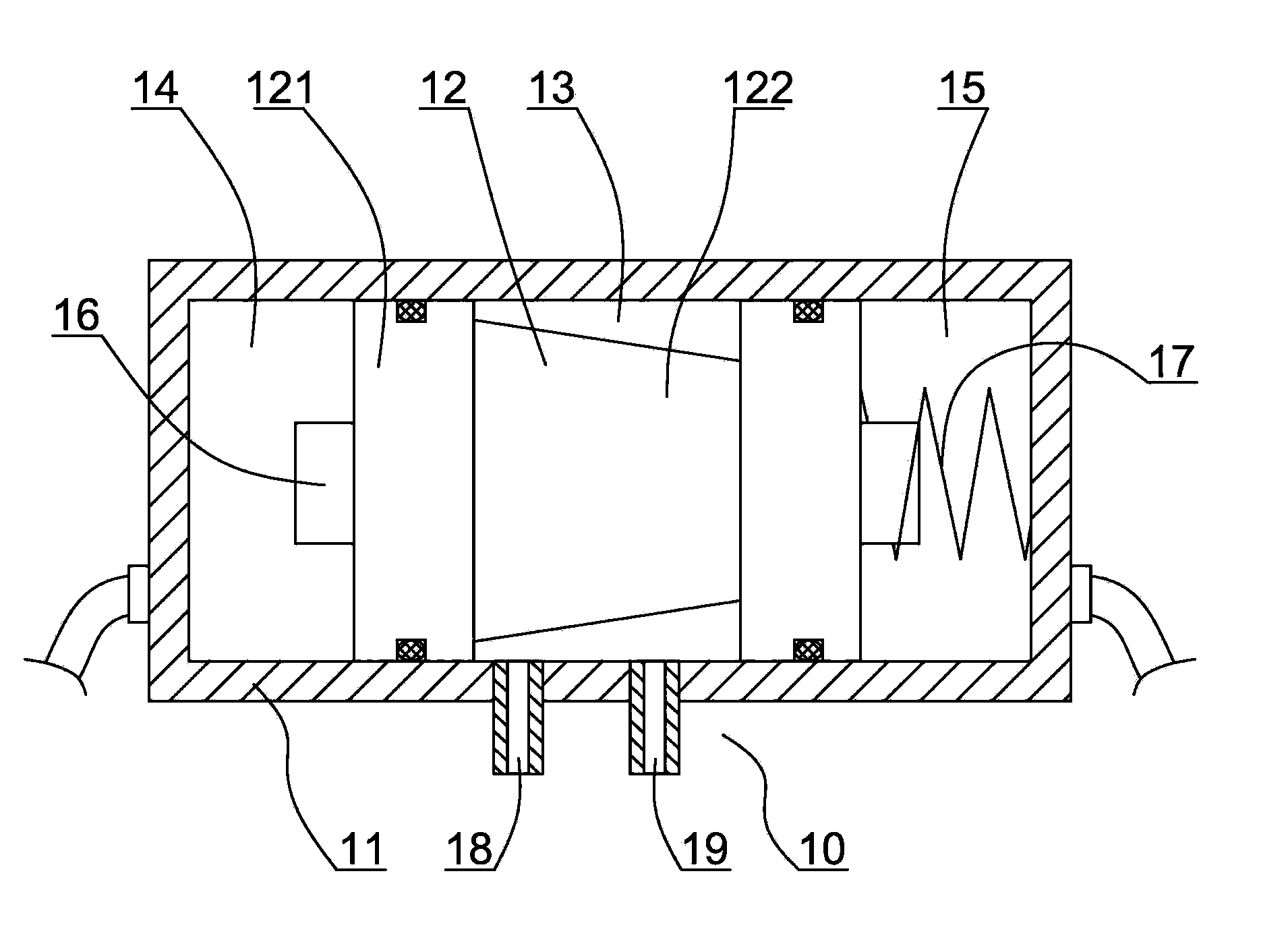

[0045] b. Connect the charging head of the refrigerant charging machine to the connection interface on the air inlet of a calibration gas tank 1. The connection interface adopts a quick connector that can be quickly connected to the charging head, and open the air inlet of the calibration gas tank. Valve, the valve can adopt existing structures such as ball valves, and a vacuum sensor for detecting the vacuum degree of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com